66

LNG

INDUSTRY

OCTOBER

2016

Other safety codes now in place include the National Fire

Protection Association’s NFPA 57 for vehicular LNG piping

and NFPA 59 for LNG production, storage, and transfer.

The Society of Automotive Engineers (SAE) has created an

LNG code J2645 for vehicular system recommendations.

The Department of Transportation also addresses safety

with regard to LNG-powered vehicles. Beyond these, there

are 12 additional prominent organisations that offer safety

recommendations for the use of LNG.

2

These include,

but are not limited to, the American Gas Association,

Underwriters Laboratories, National Institute of Standards

and Technology, and the American Petroleum Institute (API).

Today, most owners and operators of LNG systems have

learned that safety is essential from both a moral

responsibility perspective and a litigation point of view.

Essentially, it is unwise to use LNG pipe and pipe systems

that are not designed, manufactured, installed and operated

in accordance with acknowledged good practices and well

known standards. Safety is ultimately the system owner’s

responsibility. The ASME B31.3 code states that: “The owner

of a piping installation shall have overall responsibility for

compliance with the code, and for establishing the

requirements for design, construction, examination,

inspection, and testing which will govern the entire fluid

handling or process installation of which the piping is a part.

The owner is also responsible for designating piping in

certain fluid services and for determining if a specific quality

system is to be employed.”

3

In some US states and

Canadian provinces, pipe systems are mandated by law to

be put into service in accordance with ASME B31.3. Thus,

safety is mandated and violators will be punished. It is also

good practice for the system owner to specify the system to

be in compliance with NFPA standards, which describes

definite requirements for additional safety.

What do all of these codes mean to the prospective

buyer of an LNG pipe system? Firstly, it means that it is the

owner’s moral, and sometimes legal, obligation to comply

with the codes by using piping and piping components

certified in writing as code compliant. Secondly, it means

that the owner will be assured that the selected system will

be safe within all reasonable means, provided that it is

purchased from a reputable code compliant provider.

NFPA 59

By complying with NFPA 59, the buyer is assured of the

following:

The piping is designed and built in accordance with

ASME B31.3.

The LNG containment and storage vessels are built in

accordance with ASME Section VIII.

The piping and pipe supports are designed to meet

specified seismic requirements.

The pressure relief valves are designed to adequately

relieve the system pressure in case of fire using

Compressed Gas Association formulas.

The gaskets, sealant, and materials are code compliant.

The installation performed is code compliant, e.g. all

cryogenic valves are angled at no more than 45° from

vertical.

ASME B31.3

If a provider complies with ASME B31.3, the buyer is also

assured of the following:

Designer qualifications: the designer that is in charge

of the engineering of the piping system must hold

an accredited engineering degree, be a professional

engineer, hold a two-year engineering technician’s

degree, plus 10 years of relevant experience, or have

15 years of design experience that includes pressure

calculations, load calculations, and pipe flexibility

calculations.

Material traceability all the way back to the mill.

Certified welders with appropriate documentation.

Certified weld procedures for every ASME weld.

Inspected welds examined to the customer’s

pre-determined requirements including, at the owner’s

request, 100% radiographing or other examination

procedure.

All examinations preformed by a Certified Weld

Inspector (CWI).

All components, including valves, meet the

requirements of B31.3 or referenced codes and are

plainly labelled.

Functional pressure testing and written certification.

Piping designed to meet the owner’s thermal cyclic

requirements.

Code compliant written certifications for file.

Copies of all calculations including the maximum

allowable working pressure (MAWP) and the pipe

support system stresses.

Test reports showing thermal cycle testing.

Selecting a provider

It is advisable to request to see the provider’s ASME Pipe

Quality Manual. The provider should also supply valves that

are clearly labelled as B16.34 compliant and all relief valves

should be tagged as certified ASME compliant.

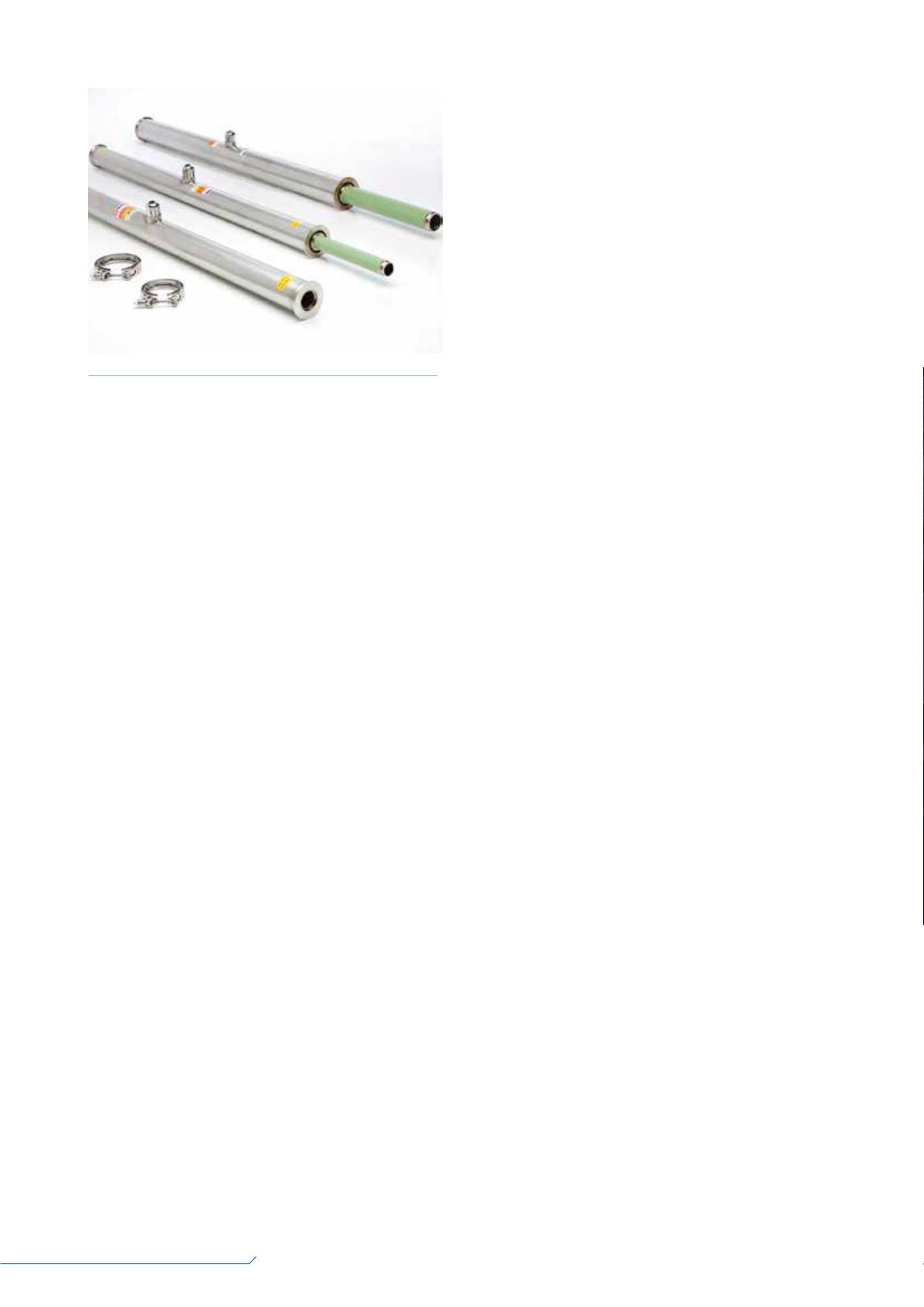

Figure 1.

Technifab Techniguard Vacuum Jacketed Pipe.

C

M

Y

CM

MY

CY

CMY

K