56

LNG

INDUSTRY

OCTOBER

2016

power generation and utilities, there is a new trend in the use of

LNG as a transportation fuel for trucks, trains and ships, instead of

diesel and heavy fuel oil (HFO).

New developments meet

increasing demands

Brazed plate heat exchanger (BPHE) technology has existed

for over 30 years and has served in multiple industries, with

the majority of sales in heating, ventilation, air conditioning and

refrigeration (HVAC&R) applications. With a normal operating

range from -196°C to +225°C and an ability to handle pressure in

the range of 40 bar, a BPHE is compact and has lowmaintenance

requirements. These characteristics are ideal for the handling of

liquefied gases. However, until now, the LNG industry has not

been able to fully utilise this technology in terms of capacity,

pressure and its common multi-stream arrangements.

What has changed is not only that the demand on the LNG

industry for small scale solutions has increased, but that there

have been significant developments in heat transfer technology

in recent years. The material race started 10 years ago, but 100%

stainless steel products have only been available frommost

producers in the last three years. Today, more exotic material

combinations for various corrosive fluids are entering the BPHE

market as well.

Approximately five years ago, the first products with seriously

asymmetric plate designs entered the market and it is anticipated

that more sophisticated solutions for a variety of applications will

be developed in the years to come. Simultaneously, there are

now BPHEs that are able to withstand 140 bar without any

external support structure and this development is spreading to

higher capacities. This is a giant leap for BPHE technology, as is

the step change in capacity where 4 in. pipes defined the

maximum capacity of this technology for over two decades.

Since SWEP, a Sweden-based company that specialises in BPHE

technology, introduced its 6 in. series in 2012, new opportunities

have opened up in the design of systems operating up to 30 bar.

In recent years, the small scale biogas liquefaction market

has established itself. Boil-off gas (BOG) liquefaction for new gas

carriers has become close to standard and a market has formed

for small scale upstream liquefaction.

The mixed refrigerant (MR) cycle is beginning to win ground

and there is a booming demand for LNG as a fuel for ships, trucks

and trains in isolated markets. Today, BPHEs can be found in

various midstream liquefaction systems, such as BOG for LNG

vessels and terminals, as well as in filling stations. BPHEs have

also proven reliable in the upstream sector with LNG and LBG

onsite production. They have also entered the LNG vaporiser

market.

Modular thinking for high

flexibility

Re-liquefaction of BOG from gas carriers for LNG/LEG/LPG

requires energy-efficient cooling without high CAPEX that might

deter some actors from using re-liquefaction systems, and it

requires a minimum of maintenance. With the basic elements of

a standard lubricant injected screw compressor and a number of

BPHEs, the modules can be combined in the most suitable way

to operate with a tailor-made mixed component refrigerant. The

BPHEs, used in the liquefaction system, play a vital part in the

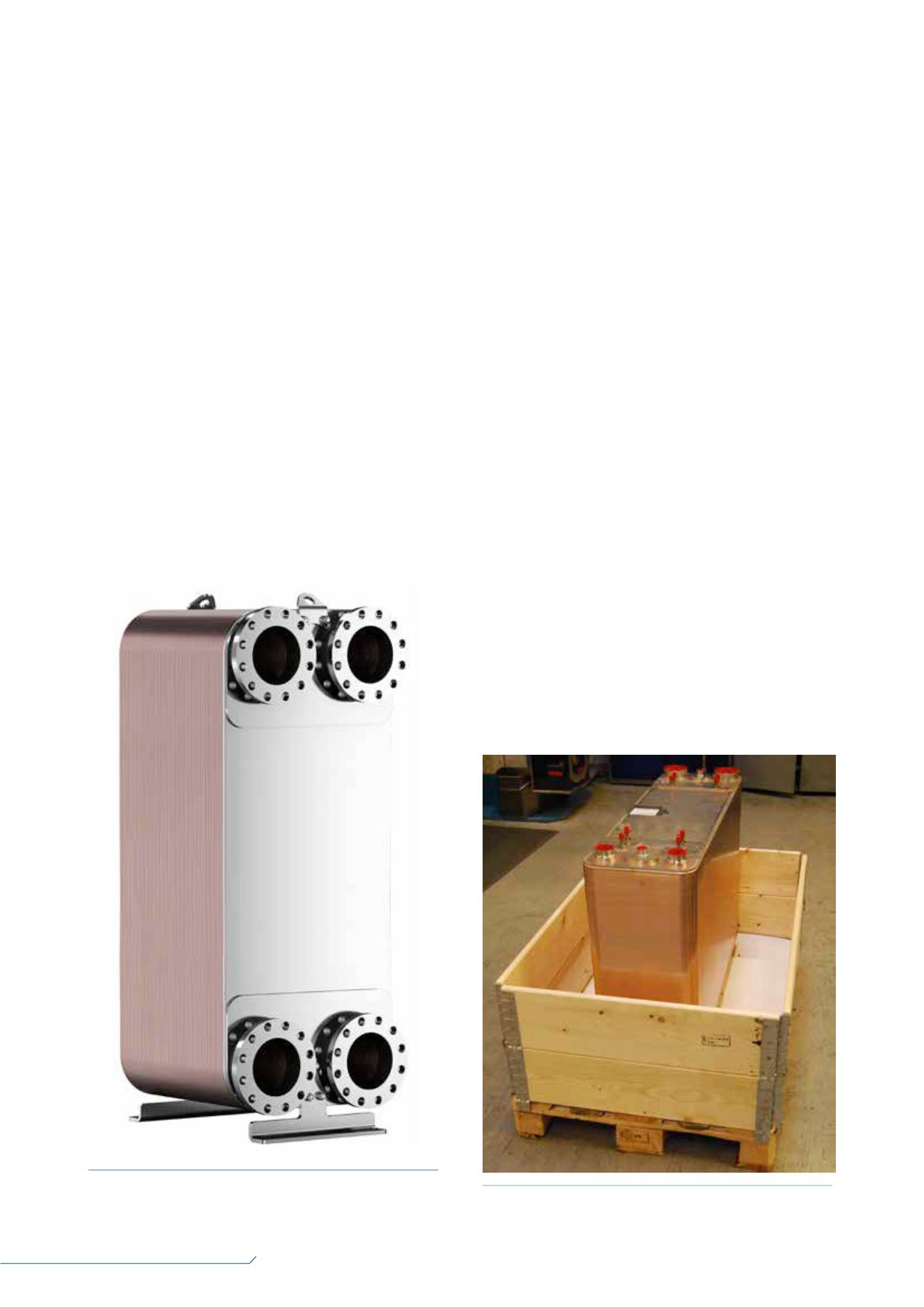

Figure 1.

A compact yet powerful brazed plate heat exchanger

(BPHE).

Figure 2.

A BPHE is easy to transport and store.