60

LNG

INDUSTRY

OCTOBER

2016

Stainless steel tubes are quite common for

applications connected to marine environments. The

classic austenitic composition of 18% chromium (Cr) and

10% nickel (Ni), with the addition of at least 2%

molybdenum, results in the appearance of one of the

most popular grades used for offshore products – TP316.

To address increasingly complicated conditions, a number

of other steels and alloys are constantly being developed.

A material is selected by weighing technical advantages

and costs. Tubes made of stainless steel need to be able

to reliably withstand design loads, but also endure harsh

conditions brought on by the proximity to salt water.

FLNG projects bring another dimension into consideration

– cryogenic temperatures.

Low temperatures are known to change the

mechanical properties of steels, often quite dramatically,

leading to decreased ductility and fracture robustness.

Unlike ferritic, duplex, and martensitic steels, austenitic

grades do not abruptly transition from being ductile to

brittle as temperatures drop, due to their stable

microstructure. The TP304L commodity steel compared

to TP316L shows lower values of elongation to breakage,

especially at lower temperatures. For instance, at -150°C,

the difference is approximately 20%, meaning that TP316L

has higher plasticity and, as such, better fatigue strength

and fracture robustness. Another advantage is resistance

to corrosion – the pitting resistance equivalent number

(PREN) of TP316L is 25% superior to that of TP304L.

Though expensive, TP316L must almost always be used

when considering a product’s full lifecycle, bearing in

mind that the typical design lifespan of a modern FLNG

facility is 20 – 25 years.

Case study

In 2013, Centravis began supplying

material to an FLNG facility developed

by Technip and Daewoo Shipbuilding

& Marine Engineering (DSME) for

Petronas (Singapore). Fulfilment of the

order attracted special attention from

an organisational and technological

point of view. It was important from

the outset to realise that such large

scale projects require a high degree of

responsibility, as even minor delays in

shipment and quality related problems

can easily snowball into major issues

further up the supply chain. One

way to minimise the risk was to

prepare and agree a thorough plan for

manufacturing, inspections, and testing

with the customer.

Stainless steel was used for pipes

both in topside and inside of the hull of

the FLNG facility. In order to

manufacture 1 in. SCH 10S – 8 in.

SCH80 (XS) pipes of TP316L, Centravis

used hot-forming and cold-forming

processes, depending on the product

size.

Manufacturing

process

To begin, the company received

round billets of raw material from the

suppliers, which were cut to precise

lengths and drilled to achieve the

internal bores necessary for high

precision diameter and wall thickness.

The billets were then coned and

faceted, heated in horizontal induction

heaters, expanded, reheated in

vertical inductors to at least 1070°C,

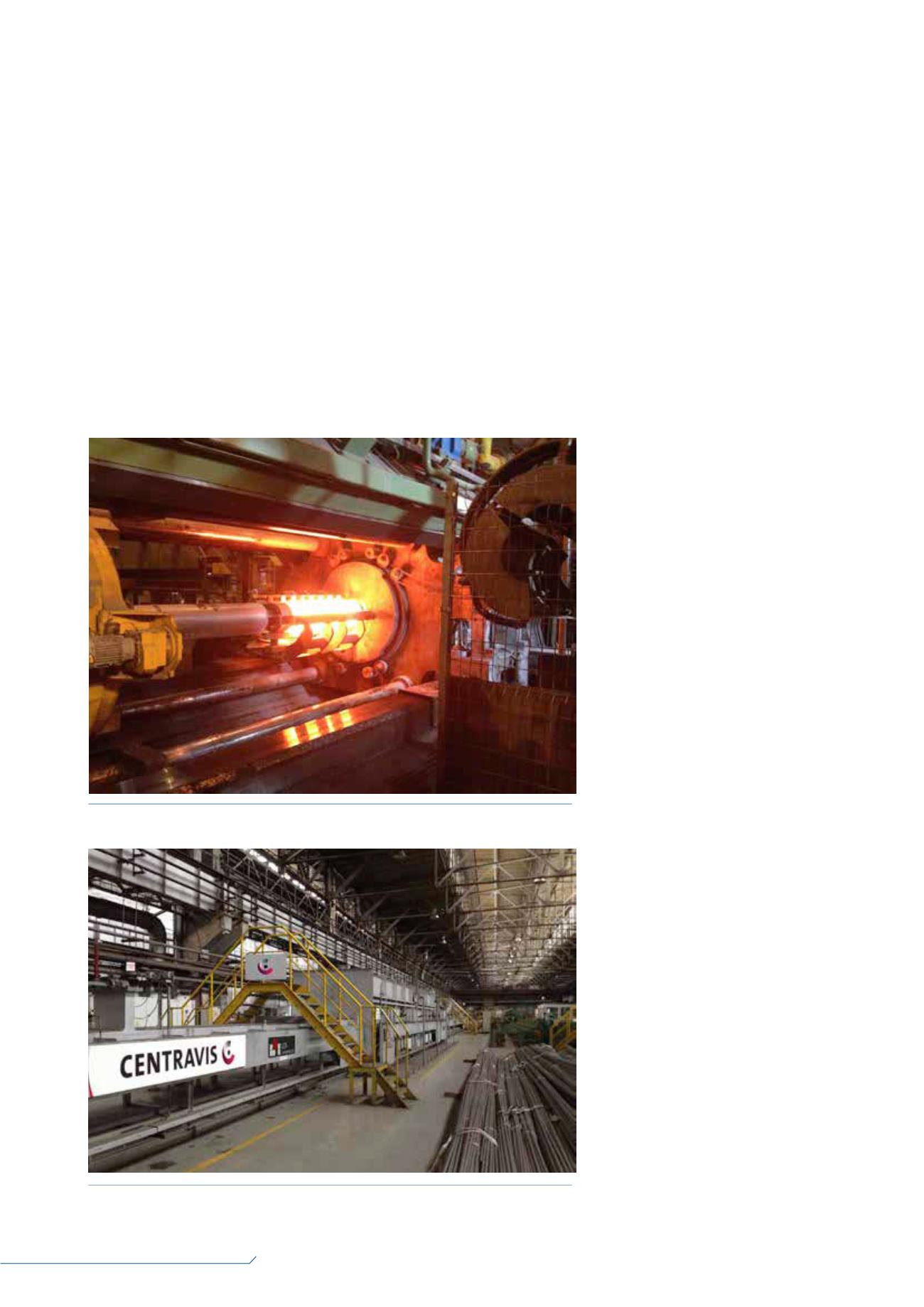

and hot extruded in a press (Figure 1),

able to generate a force of 4400 t.

Immediately following extrusion, the

Figure 1.

Extrusion of the pipe in the hot shop.

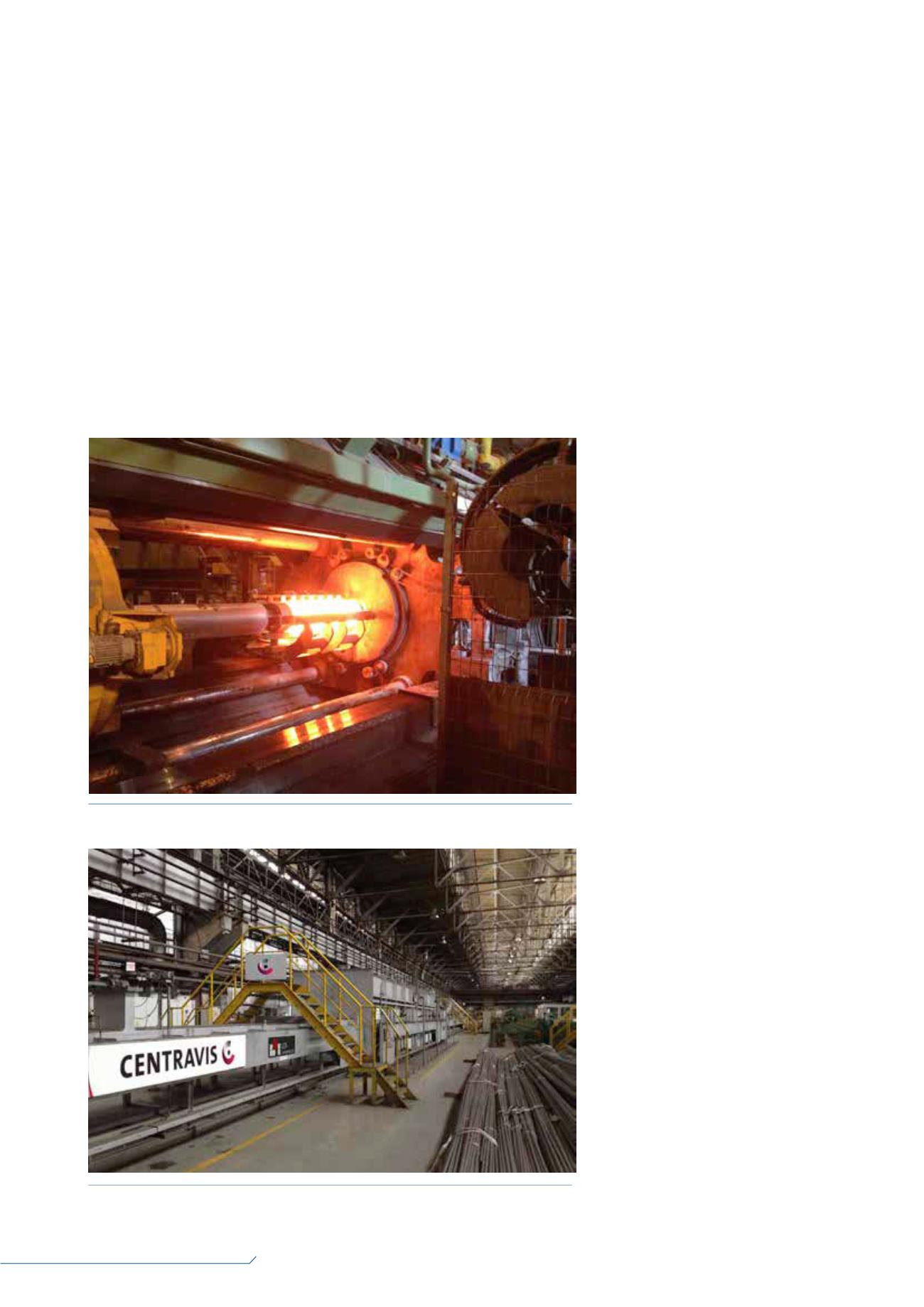

Figure 2.

Bright annealing furnace in the cold shop.