Treating austenitic steels with heat strengthens the

final products, i.e. an increase of yield tensile strengths

(YTS) and ultimate tensile strengths (UTS). As seen in

Figure 6, these two characteristics are correlated. In

general, this may allow for more reliability in the tubes

bearing the same pressure.

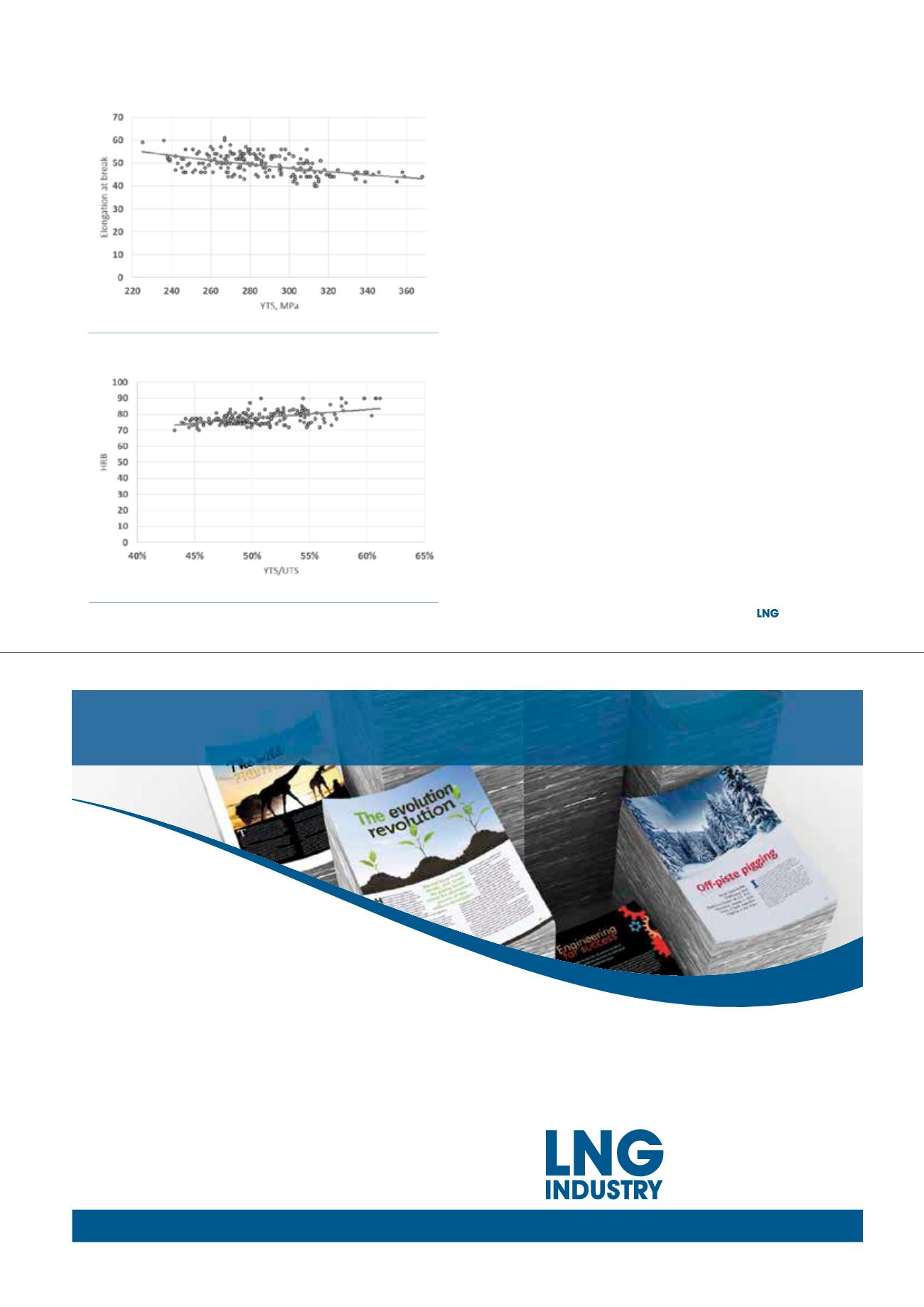

The increase of YTS, however, leads to decreased

plasticity of the metal, evidenced by lower values of

elongation at the break (Figure 7). As a side effect, this

may result in undesired lower formability of the product,

as well as higher sensibility to micro-cracks and impact

loads. In relation to the manufacturing of the tubes, it is

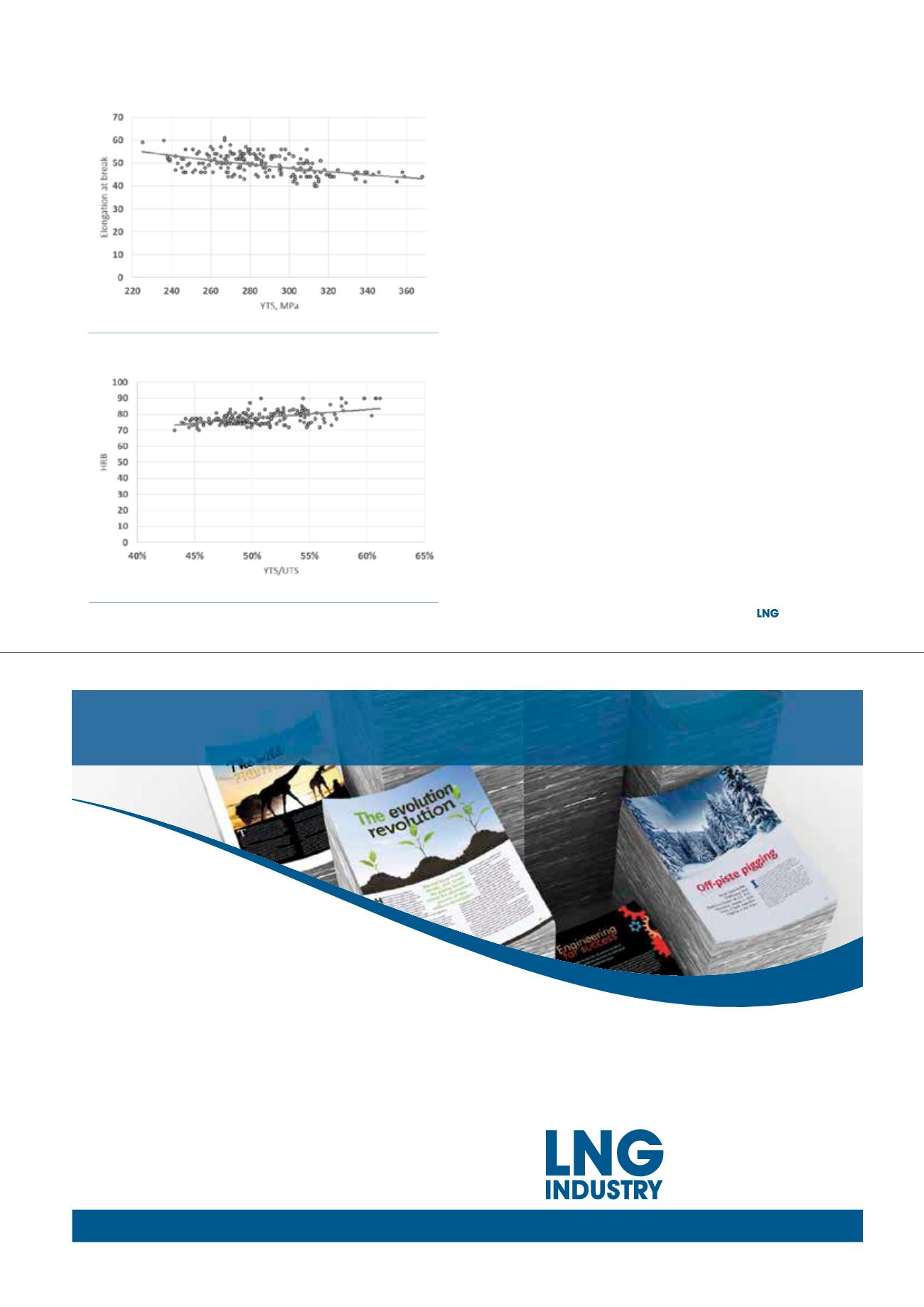

important to consider that higher YTS can lead to large

values of surface robustness as a result of applying higher

loads during straightening after annealing, leading to

higher stresses in contact between the pipe outside

diameter surfaces and rollers (Figure 8). If robustness

becomes too high, there is a risk of corrosion under stress.

Centravis has a proprietary technology that allows for

lower surface robustness and, therefore, the ability to

offer higher YTS, exceeding the minimum standard

requirement by up to 60%.

In order to maximise the value brought to the FLNG

project, the technology of tube and pipe production must

take into account a reasonable balance between all of the

parameters affecting the final product’s functionality. All

of these aspects were carefully addressed during the

execution of the company’s first FLNG order.

We can tailor to your

requirements,

produce 1 - 12 page

formats, print colour or

mono and more

Need a reprint?

+44 (0)1252 718999

Figure 8.

Hardness vs ultimate-to-yield strength ratio.

Figure 7.

Elongation at break vs YTS.