OCTOBER

2016

LNG

INDUSTRY

57

development of the SINTEF micro LNG concept. SINTEF Energy

Research has shown that BPHEs fit well into this concept and

can withstand rapid temperature changes. Having first applied

the method full-scale on board a multigas carrier in 2009, the

SINTEF research shows that the installation of a micro LNG unit

is both environmentally and financially sound.

Amicro LNG liquefaction plant often focuses on local

distribution where LNG is regasified and fed as pipeline natural

gas for local power generation, but the technology and the

concept is essentially the same as for marine BOG

re-liquefaction, with LNG filling stations connected to the gas

grid, or LBG production at a landfill site. The BPHE technology is

also a key component for cost and size efficient MRmicro LNG

systems. Small scale LNG plants have been acknowledged as

the best option for monetising marginal and stranded gas

reserves.

1

By compacting gas volume up to 600 times denser

than the standard atmospheric pressure, an LNG plant is the

safest and most efficient way to utilise natural gas.

The theory with a micro LNG plant is to standardise the

components, which substantially decreases manufacturing lead

times. With an off-the-shelf strategy, the components of the

heat exchanger can be combined into custom-made installations

at a lower investment. The plants can easily be packed up and

relocated to a new gas resource. Previously, the natural gas

sector had to choose between expensive low volume

components, or whatever mass produced parts were available,

but SWEP can now customise its existing range to fit the specific

needs for liquefaction, and can develop new products for the

LNG vaporiser market.

Unlike large capacity technologies and even mini LNG

systems, the micro LNG plant is commercially able to recover

waste gases from various organic processes, and in remote

areas. Biogas, flare gas, landfill and coal bed methane (CBM)

have so far not always been financially viable, but the micro LNG

concept allows for quick adaptation for projects where it is not

technically or economically feasible to build pipelines to

end-users. Turning previously unutilised reserves of gas into

liquid fuels decreases carbon footprint while meeting the

increasing demand of the market. One example of this is

North Dakota, US, which recently adopted tough new

restrictions on gas flaring. Much of the natural gas produced

alongside the crude oil production has been burned off at

thousands of wells, since inadequate pipeline and gas

processing infrastructure have made it impossible to capture the

gas. Amicro LNG plant would make it possible to utilise this

source of energy.

When it comes to retrofitting equipment in restricted spaces

and transportation of pre-produced racks with rail or truck to the

customer, the smaller size and decreased investment cost of a

micro LNG system is beneficial. With compact components, it is

possible to utilise existing vessels and to use other means of

transportation than across the sea. The adaptation of selected

equipment, MR and operational conditions for each application,

as well as natural gas composition, also allows for customised

solutions in older vessels.

The MR system has recently also been introduced in the

cargo handling product line-up fromWärtsilä. The company

claims that, for conventional LNG carrier capacities, MR

re-liquefaction technology is the most cost-effective solution,

and for these systems, BPHEs offer both an attractive price and

short lead times.

Case study

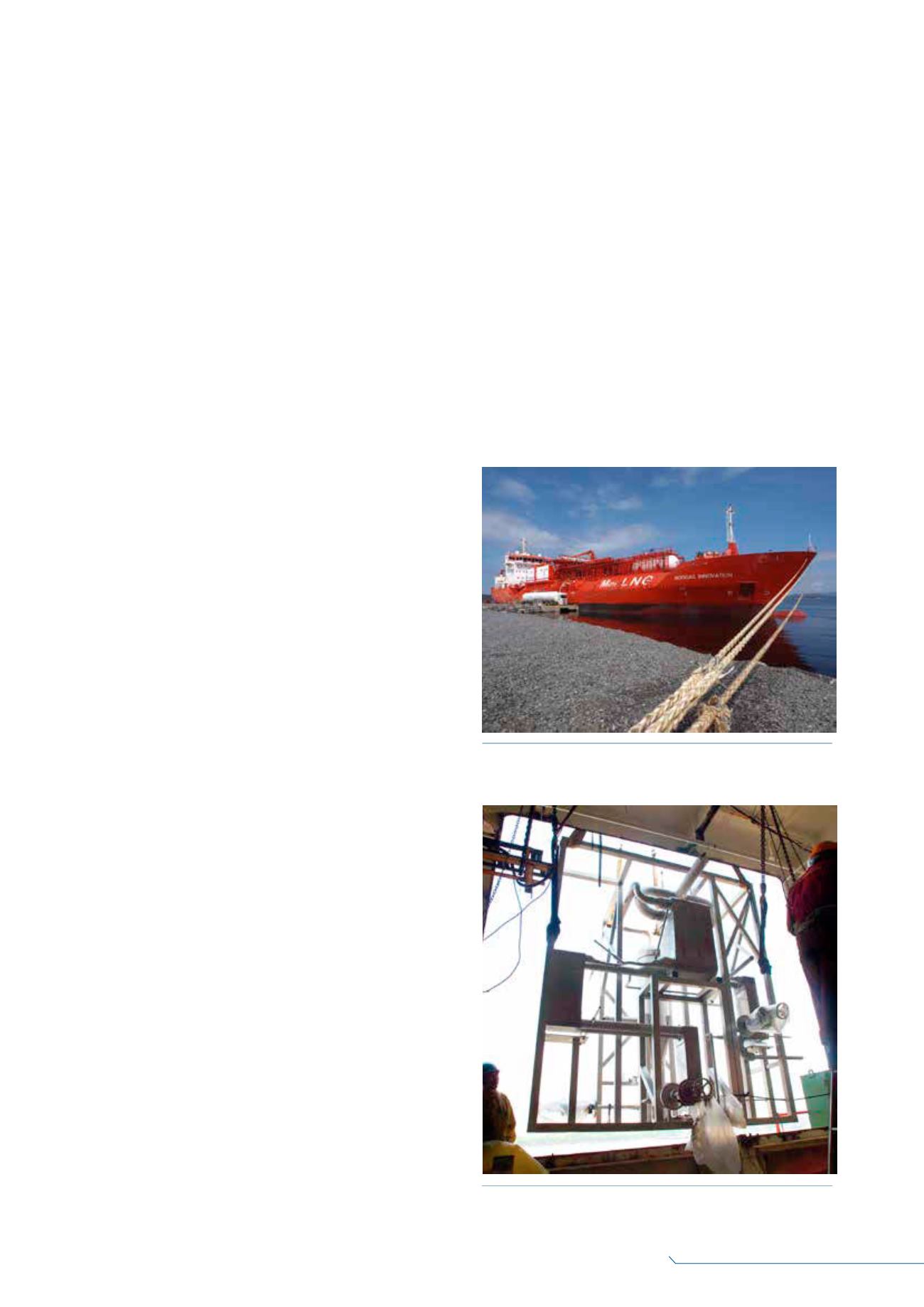

Norgas Carriers Private Ltd, a member of the

I.M. Skaugen Group, is a leading integrated shipping company

involved in the global transportation of petrochemical gases,

LPG, chemicals and LNG. The company has recognised the

growing need for environmentally friendly transportation and

fuel usage. In the past, Norgas vessels were designed for short

haul, and for cargo at a temperature of -104°C, which means

liquefied ethylene, but not methane. The re-liquefaction capacity

was only sufficient to maintain tank temperature and pressure

after loading. Later, the company developed vessels for long

haul with super coolers that were not only able to maintain the

temperature of the cargo, but also cool it down 2.5°C per day.

However, Norgas sought further improvement. Over the

years, the company has increased the cooling capacity, from

super coolers to winter coolers and multigas. In late 2009, the

first full scale plant for marine applications was installed on

board the multigas carrier,

Norgas Innovation

, in cooperation

with SINTEF and SWEP.

Norgas Innovation

featured SWEP’s

Figure 3.

Norgas Innovation

with a pioneering boil-off gas

(BOG) system.

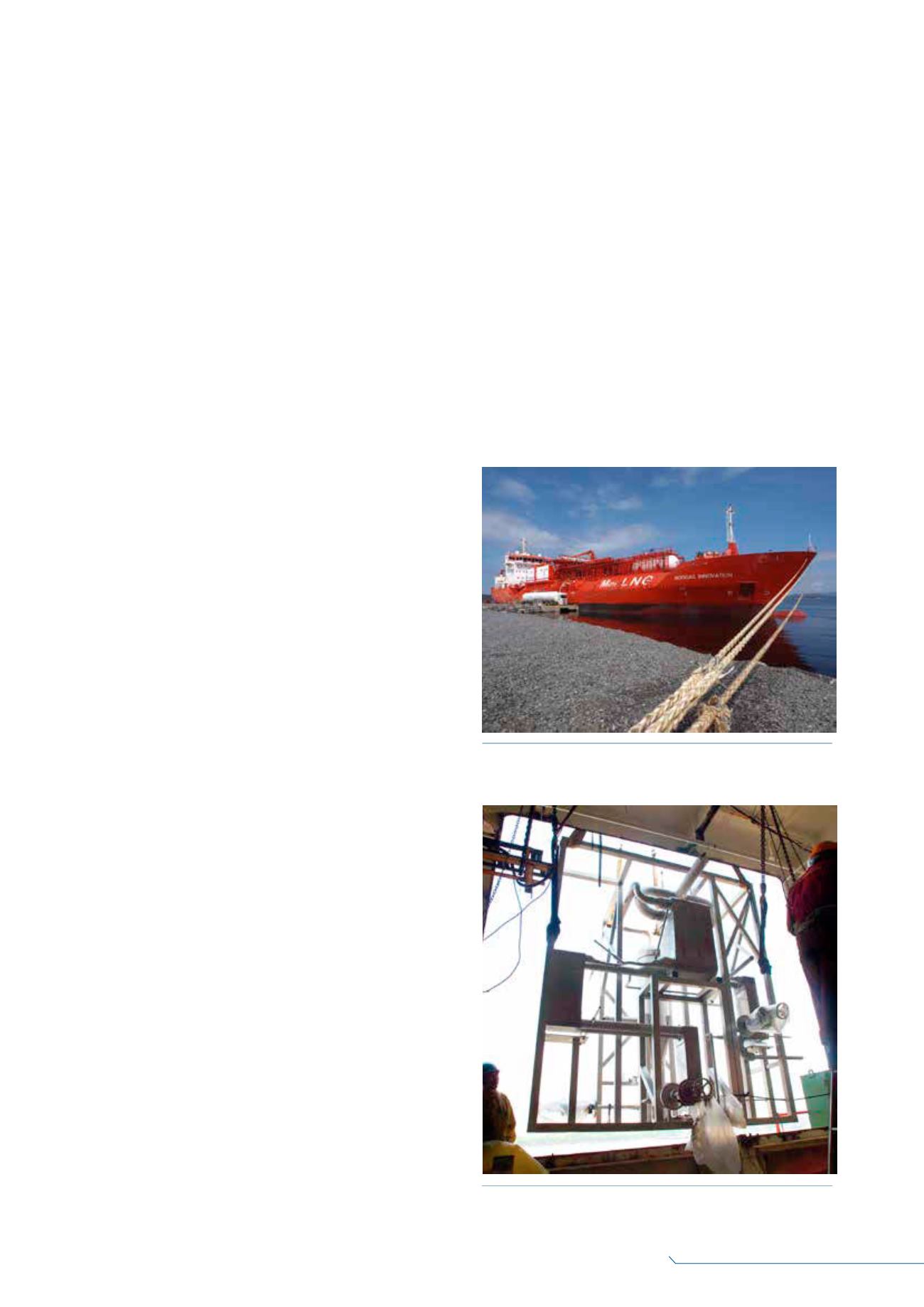

Figure 4.

Retrofit installation of a BPHE-based BOG system.