70

LNG

INDUSTRY

OCTOBER

2016

Challenges in detailed design

There are a number of challenges to consider when

designing pipe supports for cryogenic applications,

including the following:

The length and diameter of pipes shrink and expand with

each change in temperature.

Any insulation material used as an insert will shrink

differently to the pipe in terms of thickness, length and

diameter.

The support fastening system, which is separated from

the pipe by means of an insulation material, is subjected

to the changing ambient conditions and also shrinks and

expands.

Due to a water vapour pressure differential caused by the

temperature differential over the insulation, moisture is

driven into the insulation towards the pipe.

Vibration and shock resistance.

From an economical point of view, it seems logical that

standard pipe support designs, as used for non-insulated

pipes, are suitable when it comes to resting supports,

slides and guides. An insulator is required between

cryogenic pipe and the metal cradle. The choice of

insulation material depends upon the combination of

both insulation value and physical properties. However,

it can be difficult for a material to have the physical

properties to resist loads, while also providing an

adequate insulation value.

In the 1970s, hardwood (oak, irocco, okoume and

merbau) blocks were used extensively in cold

applications as loadbearing inserts between the pipe

support and the steel pipe due to the material’s

combination of high compressive strength and insulation

properties. These inserts, which were of a 60° or 90°

design, were placed between pipe and pipe

clamps. Non-loadbearing insulation, such as

cork, was used in the remaining space between

the clamp and the support.

Not only was this design proven to be

inadequate in terms of thermal performance,

but moisture ingress and icing also occurred

after only a short period of operation,

defeating its purpose.

Polyurethane was discovered by

Dr. Otto Bayer around 1930, and higher

densities in rigid foams were developed

around 1950 – 1960. The manufacturing

technique includes block forming and cutting,

injecting, spraying and precision molding.

In 1973 – 1974, R&D work resulted in a high

density precision molded polyurethane

product with high density skins as loadbearing

insulation for cryogenic supports. The unique

features of this product were that it combined

Figure 3.

Guangdong LNG terminal; China’s first LNG receiving terminal (courtesy of Saipem).

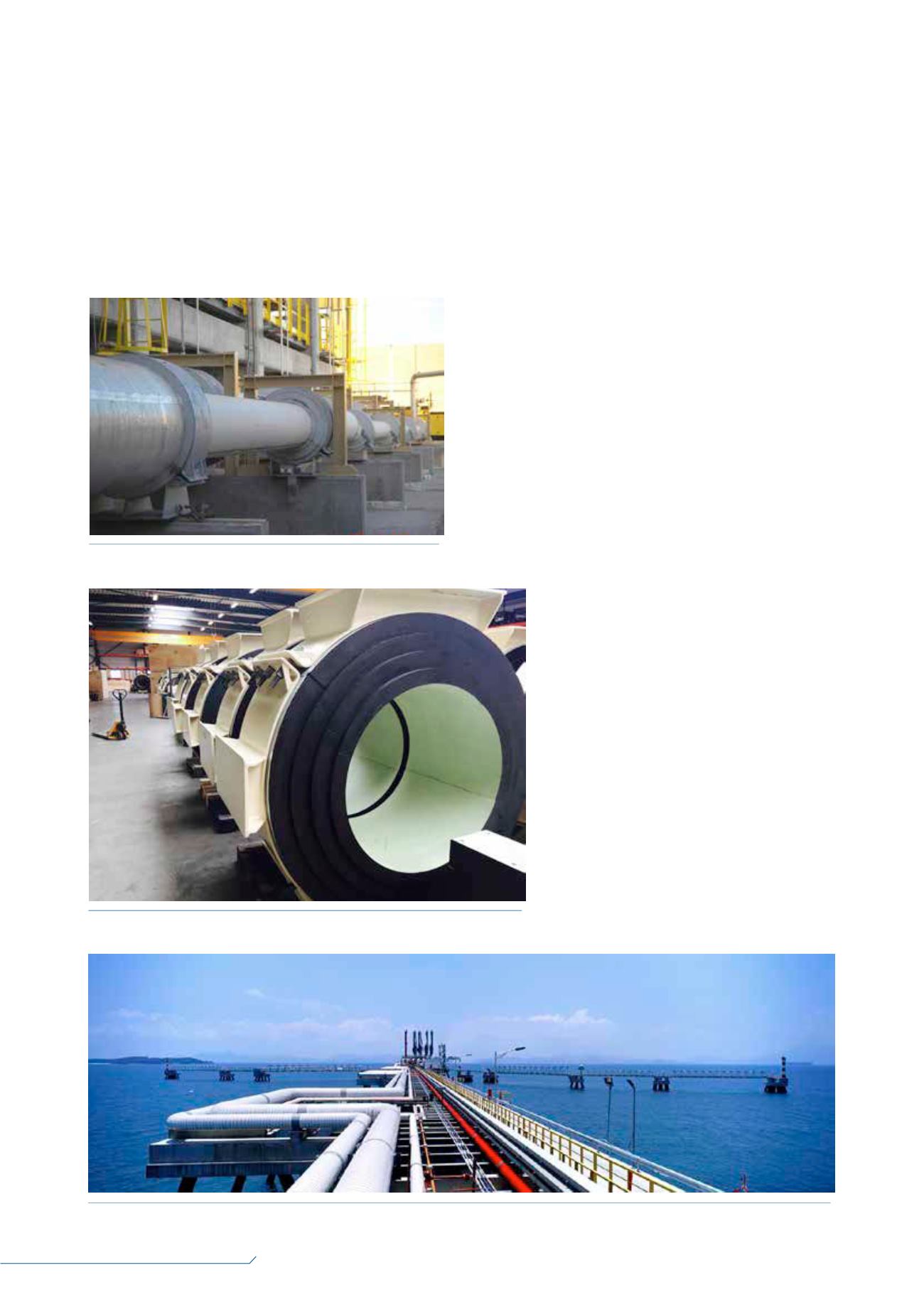

Figure 2.

Yamal LNG; 36 in. cryogenic supports awaiting inspection.

Figure 1.

Sagunto LNG terminal.