34

April 2020

the multiplication of the reliability of each component. Since

there are many components, the reliability can be estimated

using the reliability of some key modules such as the diode

assemblies, power module assemblies, etc. The reliability of

the VFD will be less than the reliability of the least reliable

module:

Where ‘R

VFD

’ is the reliability of the VFD, and ‘R

M

’ is the

reliability of each module. For example:

Other than intrinsic reliability, redundancy can be built in

many configurations with the increased number of

components. One form of creating redundancy is installing

duplicate systems in parallel, known as hot redundant

systems. In this configuration, the components or modules

operate all the time, sharing the load. When a path fails, other

paths continue to operate, ensuring power delivery. Only when

all paths fail will the entire system fail. Because the parallel

circuits run at the same time and share the load, they age

equally and can be affected by large technical failures.

When the failing rates of each chosen module (F

M

) have

been accounted for and recorded, the reliability of the VFD

can be estimated using:

Where ‘n’ is the number of modules under consideration, ‘t’

is the time of operation and ‘F’ is the probability of failure.

But, since failure rate can be expressed as Fi(t) = 1– Ri(t),

where ‘F’ represents the probability of failure of the ‘i

th

’

module, and ‘Ri’ represents the reliability of ‘i

th

’ module, the

reliability can also be calculated using:

There are other configurations of circuits or components

in use in VFDs to create redundancy, as well as many

combinations of redundancy methods, all of which add more

components and complexity to the equipment.

When standby modules, circuits or components exist, the

reliability can be calculated as:

Where ‘n’ represents the number of standby modules or

circuits or components, ‘t’ represents time, and ‘

λ

’ represents

the failure rate. When only one standby module, circuit or

component exists, the expression becomes:

The same expression can be used when a whole VFD is

used to standby for many other equal VFDs in a production

facility, or the operation employing one VFD is supercritical.

VFDs are maintainable and, in most cases, preventive

maintenance is economically viable and highly preferable over

corrective maintenance. To plan for maintenance works, the

uptime availability of the VFD can be used.

The uptime or steady-state availability is defined by:

Where ‘A’ is the availability of the VFD, MTBF means

mean time between failure, and MTTR means

mean time to repair exclusively dedicated to the repair. In

other words, excluding, for example, waiting times for parts,

tools and setup time. Figure 6 highlights steps accounted for

as MTTR.

Over time, the availability of a VFD can be retained

through weekly-monthly inspections observing the following:

z

Changes in the installation environment, such as

temperatures, appearances of dust, humidity and gases.

z

Abnormal sounds or vibration in the transformer, or

cooling fans.

z

Unusual smells of insulating substances, peculiar to

electric circuits failure.

In addition to regular inspections focusing on:

z

Maintaining the interior of the cubicle and keeping the air

filters clean.

z

Looking for part discoloration, deformation, leakages of

components, circuit boards and wiring.

Identification of fault on

VFD panel

Repair or set up

Removal of

faulty part

Installation of

new part

Preparation for

operation

Turn supply

power on

Checks before

powering

Closing doors

Figure 6.

High-level repair process.

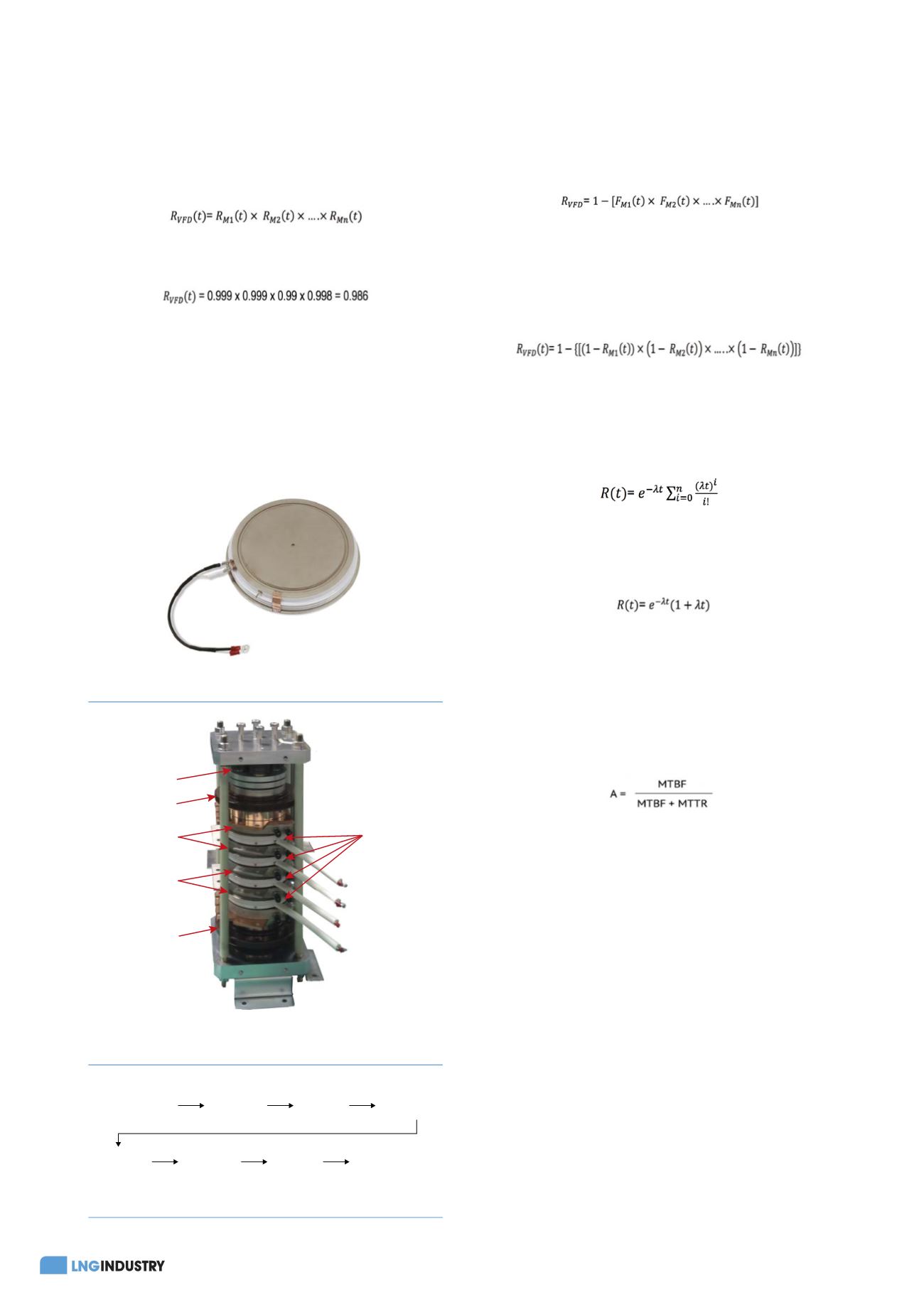

Press Pack

IEGT

Spring

Insulator

Cooling Heat

Sink

Insulator

Cooling Heat

Sink

Figure 5.

Example of a PPI assembly (stack).

Figure 4.

Injection enhanced gate transistor (IEGT).7