40

April 2020

temperature, there is insufficient bearing clearance for

operation. Cooldown MR gases pass over the bearings

through channels to ‘shrink’ the bearings and open up

bearing clearances to enable operation. Even during

operation, the bearings on each side of the 1 MW generator

require cooldown gases because of the nearby heat energy

coming from the generator. This is especially true for the

middle bearing.

The liquid expander cools down approximately 300 tpd

of MR, but, during the startup sequence, the entire

production is delayed because the bearings have to be

precooled before operation. The plant manager and the

expander OEM decided to shorten the startup time by

allowing cooldown gases to flow through the expander and

bearing channels at the same time in order to speed up the

cooling process. This recommendation was also given to

another plant.

After the new startup sequence was implemented, there

were problems. Although there was no load on the

compressor, the rotor started to spin due to the cooldown

gas flow through the impeller, thereby putting stress on the

bearings before they were at operational temperature. This

is what caused the bearings to begin to prematurely fail.

Benefits

After this discovery, the new startup sequence was

discontinued and the original one was re-implemented.

Fortunately, while the new startup sequence was in use,

there was no catastrophic failure of the liquid expanders

because the monitoring system was capable of detecting

and diagnosing the rapidly progressing fault in the liquid

expanders at both LNG plants, before the protection system

tripped. This lead-time allowed for a proper shutdown

sequence.

Early detection of a propane

compressor gearbox fault using

diagnostic measurements with trend

alarms

The propane compressor train gearbox in this case

study connects the axial compressor to the 75 MW

Frame 7 gas turbine. There is also a variable speed starter

motor/generator at the other end that is used to help start

the gas turbine, and afterwards the unused power from the

gas turbine turns a generator which supplies power to the

grid. The four-stage single casing centrifugal compressor

uses propane at four different pressure levels to supply

refrigeration to the incoming natural gas and precooling of

the MR (C3MR process).

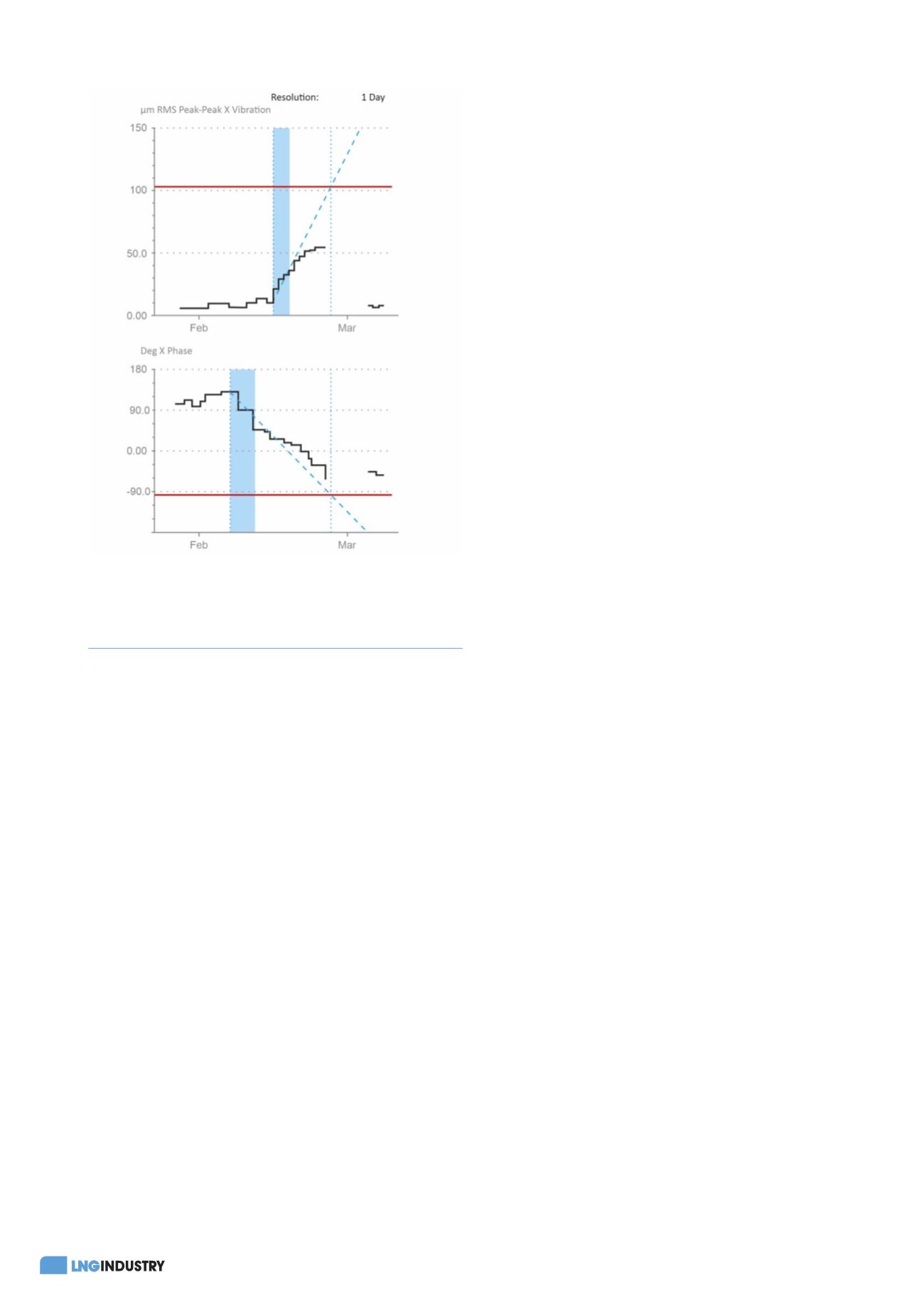

Trend alarm warning

Not long after service, one of the propane compressor

trains at a major LNG plant gave signs of trouble at startup

(Figure 3). The overall vibration amplitude was within

limits, but the specialised fault detection measurements

of the monitoring system told another story (Figure 4). An

alarm trend warning for the first order phase measurement

indicated that the detected fault trend in the propane

compressor gearbox would reach a danger alarm limit

within 14 days. As the fault severity was determined to be

low, operations continued, but maintenance preparations

were already being made. Four days later, the first order

magnitude measurement gave an alarm trend warning of

10 days, but still no alarms related to the overall vibration

(Figure 4). Eight days after this, there was an exceeded

alarm limit for the overall vibration signal. Thankfully a

decision had already been made to perform a machine

shutdown to investigate, therefore preparations were

already underway.

Not a defect or wear issue

Machine condition monitoring is not limited to detecting

component damage or wear. In this particular case, it was

the spur gear on the output side of the gearbox that was

found to be improperly mounted.

Benefits

The specialised measurement techniques with a trend

alarm proved to give much earlier and more reliable fault

detection than the overall vibration measurements. This

extra lead time can be very important when dealing with

fast deteriorating gear faults, such as this one, in order to

cost-effectively prepare for maintenance.

Defect bearings installed on the

instrument air compressor

The instrument air compressor serves a critical role in an

LNG plant, as well as in other industries. It provides clean,

dry air that is used in a range of control and shutdown

valves. There are three oil-free centrifugal compressors

per train at the LNG plant. The three-stage instrument

air compressor is driven by a motor though a gearbox

Figure 4.

Automatic trend alarms for the first order magnitude

(top) and phase (bottom) measurements from the middle bearing

accelerometer. The phase trend alarm occurred four days before

the magnitude alarm.