42

April 2020

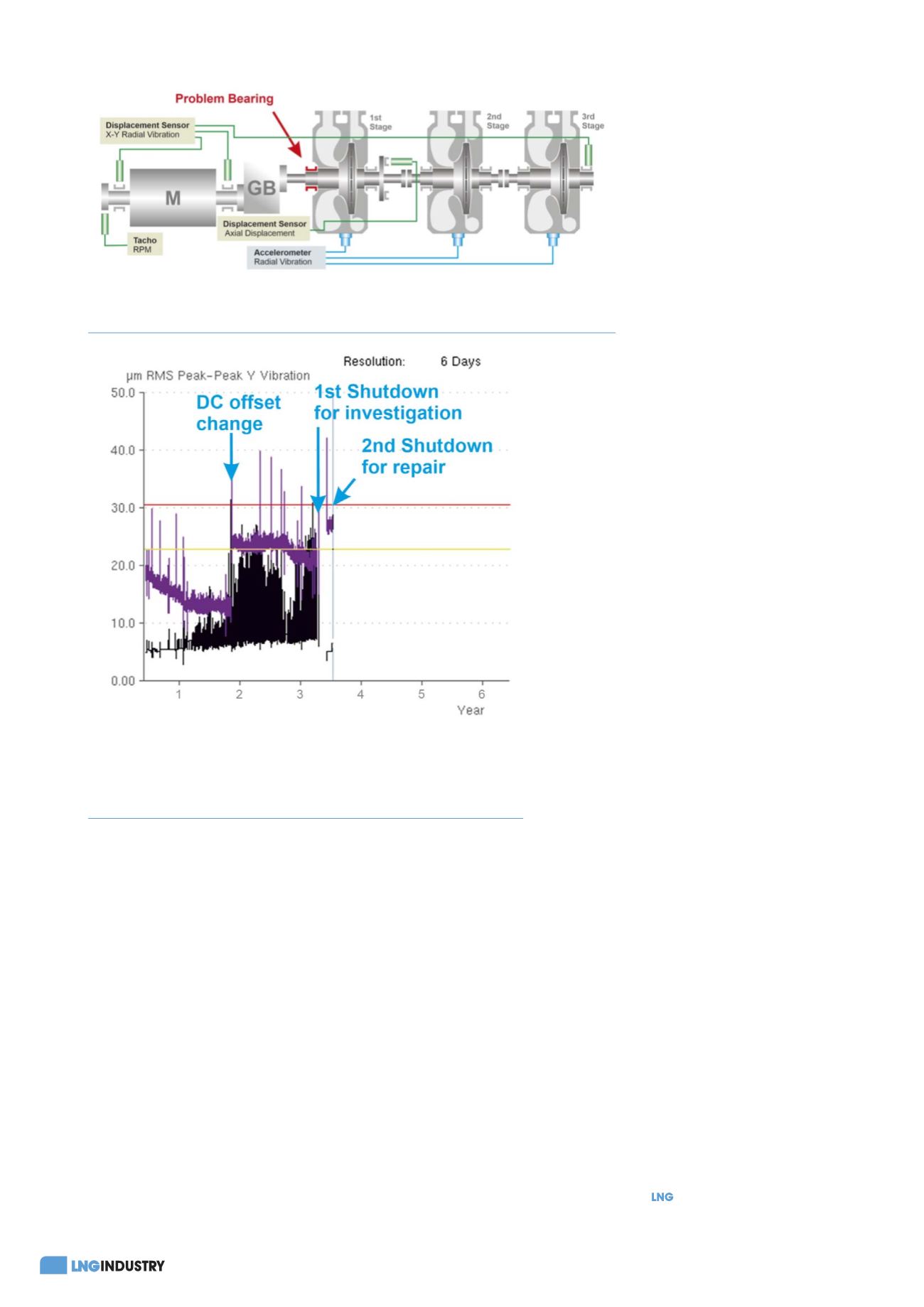

using tilting pad journal bearings (Figure 5). The units were

relatively new and still under warranty at the time of this

case study.

Observations

The third order bandpass vibration level on the inboard

bearing of the first stage impeller had steadily increased

for one year since startup (Figure 6). It subsided for a

few months, but then began to increase again, and, after

two years, it exceeded the alert alarm limits. Nothing was

found after a quick investigation so the compressor was put

back into service.

The vibration levels remained above the alert alarm

limits after startup, which led to a series of tests being

performed to try and identify the problem (e.g. changing the

lubrication). The customer was not able to reduce the

vibration levels, so the monitoring system supplier was asked

to look into it and evaluate the problem. As the vibration

levels began increasing towards danger alarm limits, the

machine was shut down. Due to the compressor still being

under warranty, the manufacturer

was contacted to investigate the

bearing.

Diagnostic analysis

It was surmised that vibration

level increased for a while,

decreased, and then increased

again as a result of a bearing fault

that initially sorted itself out for

a while and then redeveloped

again (Figure 6). The DC vibration

displacement shown in the same

figure shows a more or less linear

change in shaft position over a period of more

than three years. This indicates gradual wear of

the bearing.

Root cause analysis

The manufacturer has determined that the

fretting on the first stage bearing was due to poor

bonding of the bearing surface, as a result of a

manufacturing defect. This evaluation is based

on the fact that the high vibration levels had

already started an upward trend not long after

commissioning. All bearings were subsequently

replaced.

Benefits

The monitoring system successfully detected

a fault at an early stage of development while

the compressor was still under warranty. The

monitoring system played a vital role here since

four harmonics of the vibration signal were

individually monitored. The vibration response

of different machine faults manifests itself with

different harmonics, and in this case it was the

third harmonic that gave the earliest indication of

a bearing fault. The fault was slow to develop, so

long-term trend capability was necessary.

Conclusion

The operation and maintenance of LNG assets is extremely

demanding, due to the inherent nature of LNG processes and

production. For this reason, machine condition monitoring

plays a critical role in ensuring maximum uptime and reduced

lifecycle costs.

Component degradation due to fatigue and wear covers the

majority of faults that are typically detected, but, as seen in the

case studies, some faults can also be caused by assembly and

manufacturing errors. An effective condition monitoring solution

is critical to the detection of these kinds of faults early and

reliably, and especially before a machine’s warranty runs out.

More importantly, legacy condition monitoring systems that

are 10 – 15 years old may no longer be able to provide the

potential value that modern solutions offer today. Indeed,

technology has changed, fault detection has become more

refined, diagnostics are becoming more automated, data science

has advanced and statistical analysis and prognostic capability

is becoming more reliable and accurate with the vast quantities

of data that are now available.

Figure 5.

Vibration sensor configuration of the liquid expander. The bearing where high

vibration was detected is shown in red.

Figure 6.

The third order bandpass vibration trend (black) from the

inboard bearing of the first stage impeller over a period of several years.

The DC vibration displacement (purple) shows shaft position. (Note: an

offset change was made at the end of year 1, as can be seen in the figure.)