premature failure. Simply using harder materials does not go

far enough to address the problem and can introduce

unnecessary expense. It is more effective to address the

problem at source with applied engineering skill.

Severn primarily uses specially designed trims, such as

its own multi-labyrinth trim (MLT), to address some of the

most arduous challenges surrounding velocity and pressure

in cryogenic valves. With an MLT, the incoming flow medium

is segmented into smaller streams, each of which follows a

tortuous path of multiple flow turns which achieve

reductions in pressure and velocity. This technique removes

kinetic energy and lowers pressure in a controlled manner.

The number and nature of the turns is precisely calculated,

based on the expected fluid velocity at the inlet and the

optimum velocity at the outlet. In this way, flow speed can

be carefully controlled in each flow passage within the

valve, ensuring operation is managed purposefully across its

entire service range.

MLTs are especially well suited to compressor anti-surge

valves where performance is greatly enhanced through

well-controlled velocity of the cryogenic fluid. This solution

can reduce the vibration and noise typically associated with

LNG compressors, as well as improve reliability and extend

valve life.

Retrofitting cryogenic valves

It is not just new LNG projects that can benefit from

customised trims for cryogenic valves. When production

volumes increase at existing plants, the cryogenic valves

originally installed may no longer be fit for purpose.

Replacing them with new products is costly and often

takes too long, but strategic retrofit solutions offer an

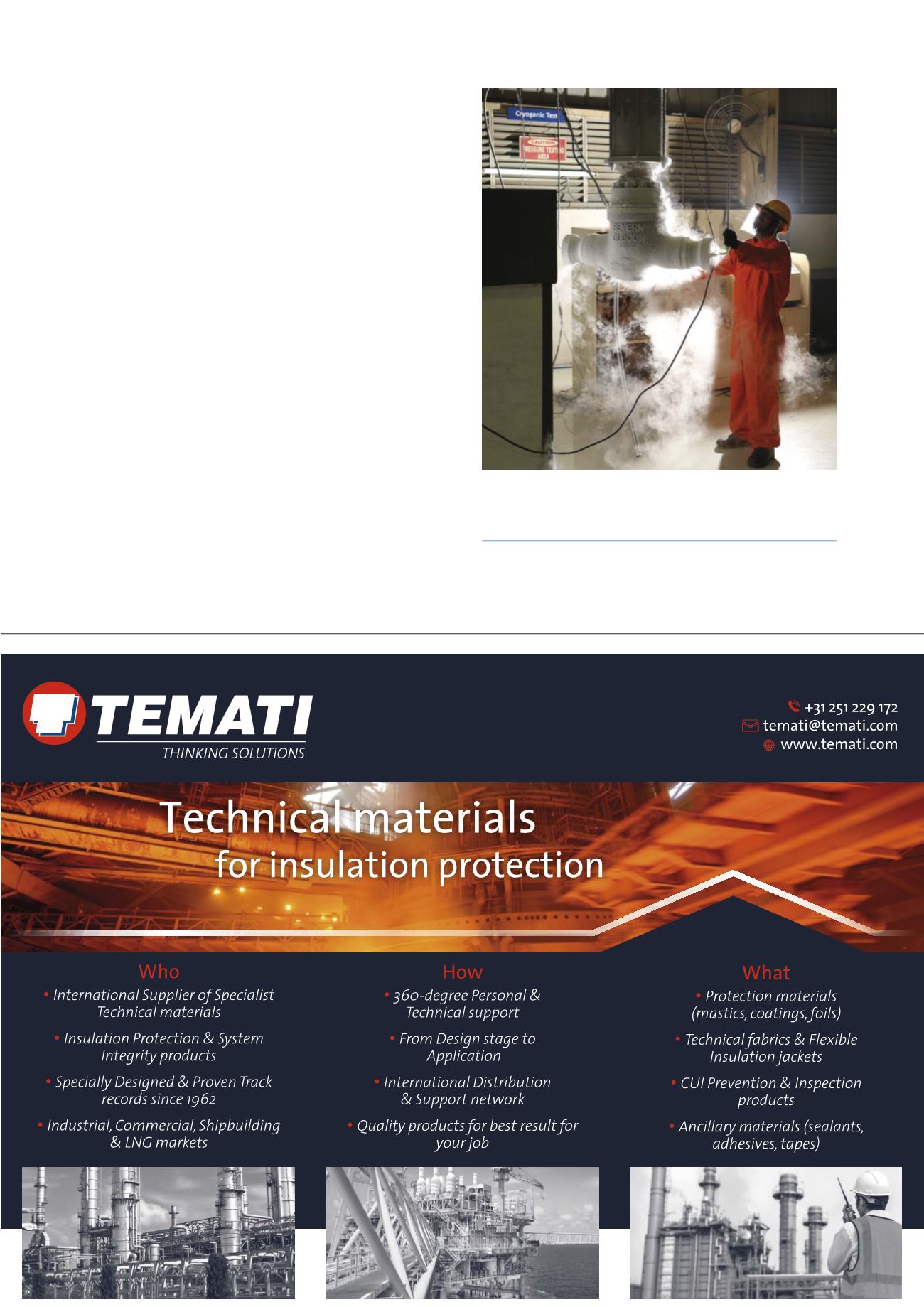

Figure 2.

Thorough cryogenic testing reduces the risk of

problems during startup.