50

April 2020

systems are replacing fuel fired heating systems. Electric

heating systems also provide added benefits when

compared to fired heating systems, including: reduced

footprint, lower installation and maintenance costs,

reduced downtime, and extremely accurate temperature

control.

In the past, the biggest restriction to considering

electric process heaters was the large amperage

requirements when using low voltage (up to 690 V)

for the power supply to the heating systems. With the

advancement of Chromalox’s DirectConnect™ technology,

large process heaters can now be operated on medium

voltage (up to 7200 V) and reduce amperage and wiring

size requirements by a factor of at least nine times.

Electric heating systems have reduced footprint due to

the ability to directly heat the process fluid. By

comparison, most fired heaters indirectly heat the process

fluid. The direct heating capability of electric heaters

allows for a more compact footprint to deliver the same

heat energy as a similar sized fossil fuel fired heating

system. Electric process heaters also have design

flexibility and can be installed in either horizontal or

vertical orientations.

Lowers installation cost

When comparing the installation costs between electric

and fired heating systems, the entire installation

and process associated with the project needs to be

considered. As noted above, fuel fired heating systems

typically indirectly heat the process medium, which

requires additional equipment, such as a heat exchanger

and the required piping to and from the fuel fired heat

source. The additional equipment and piping not only

adds cost to the project, but also the time to design

and install piping, which may require high temperature

and pressure valves and piping. With electric process

heating systems, the piping runs to and from the process

are limited since electric heaters can easily be placed

outdoors and in Class 1, Division 1&2 electrical hazardous

rated areas. The ease of installation and closer proximity

to the processing area drastically reduces installation time

and costs, while increasing overall safety at the facility.

Maintenance for an electric heating system is almost

negligible when compared to fossil fuel fired heating

systems. Electric heating systems include a flanged

immersion heater, which has many individual resistance

heater elements attached to the flange tube sheet. The

flanged heater bundle is then installed into a

pressure vessel or storage tank. There are no

moving parts, tuning of the fuel train, blowers

and soot clean out required with an electric

heater bundle. Regular checks on the electrical

connections is all that is required. The heater

control panel can feature many diagnostics and

communications to confirm the operational

health of the electric heating system. Electric

heating systems also do not require a dedicated

operator since electric heating systems are

considered an unfired vessel and do not need

the same operator and inspector investments.

Fast maintenance

turnaround

Downtime is one of the most costly issues which

affects LNG and other gas processing facilities.

Electric heating systems have no moving

parts and do not burn fuel to generate heat,

Table 1.

480 V construction

Product

Process heaters

US$1 917 000

Power control panels

US$1 692 000

Startup service

US$78 000

Sub-total

US$3 686 000

Installation

Transformer

US$1 196 000

250 ft run to panel

US$1 686 000

500 ft run to heater

US$3 371 000

140 labour hours

US$63 000

Sub total

US$6 316 000

US$10 001 000

Table 2.

4160 V construction

Product

Process heaters

US$3 728 000

Power control panels

US$1 355 000

Startup service

US$78 000

Sub total

US$5 160 000

Installation

Transformer

-

250 ft run to panel

US$183 000

500 ft run to heater

US$438 000

50 labour hours

US$34 000

Sub total

US$655 000

US$5 815 000

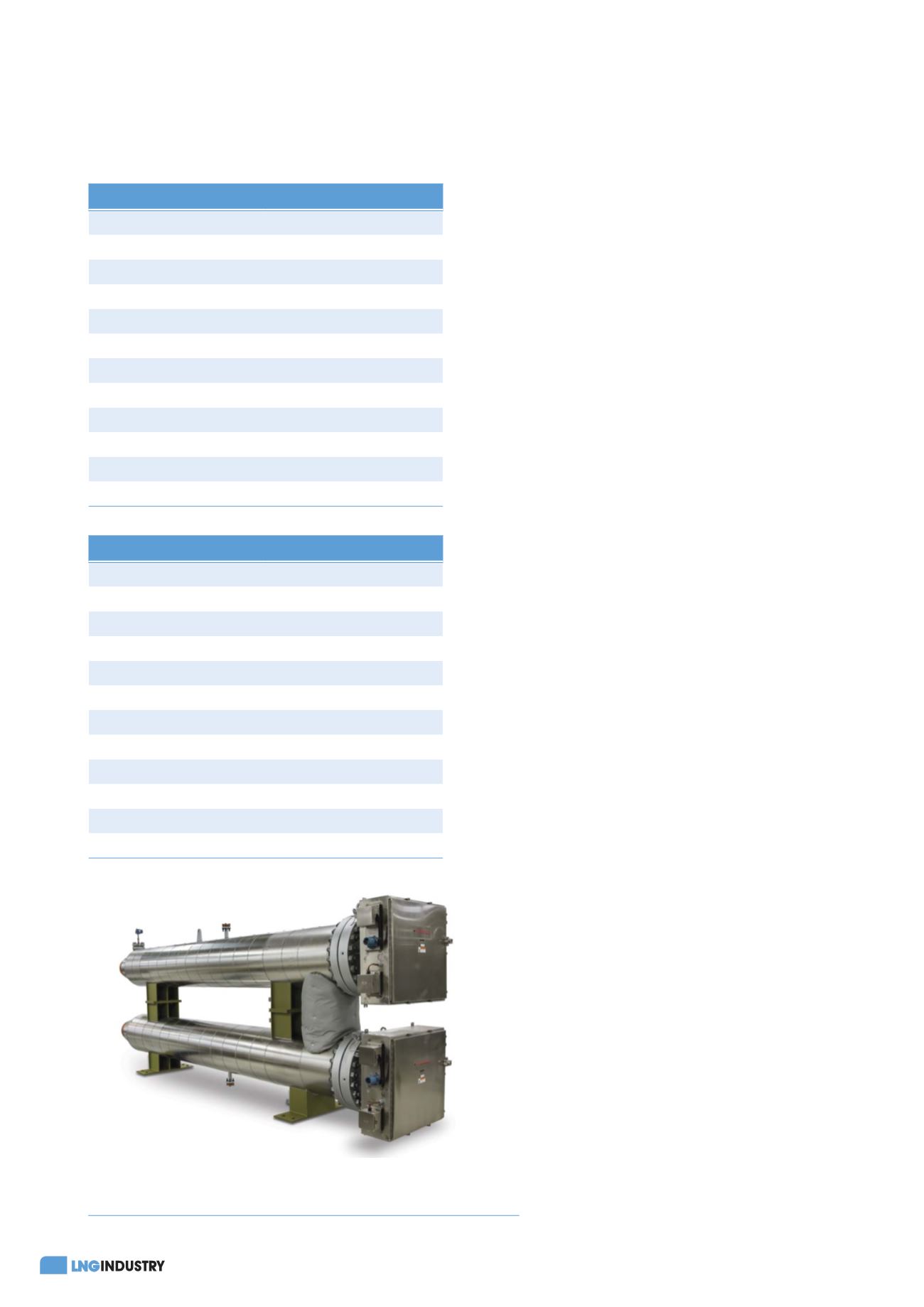

Figure 2.

Chromalox DirectConnect™ medium voltage electric systems.