catastrophic failures. Three case study examples

highlight this.

A closer look at liquid expanders

The liquid expander plays a major role in the propane

precooled mixed refrigerant process (C3MR) to make

LNG. For the mixed refrigerant (MR) expander (there

is also an LNG expander downstream), a pressurised

MR stream from the heat exchanger is isentropically

expanded with a pressure drop in the MR expander

down to -130°C, so that it can be put back into the heat

exchanger for further cooling. The liquid gas expansion

is performed by the turbine portion of the liquid

expander, where work is extracted from the gas/liquid

mixture to turn the rotor, which in turn drives the

generator. As the liquid expander is a cryogenic machine,

the thermal loading on the components, and especially

on rolling element bearings, can lead to component

failure if not properly brought to load and controlled during

startup.

Different plant, same fault

At one particular LNG plant, the liquid expanders had been

operating without mishap for several years, until a bearing

fault was suddenly detected in one of the expanders during

a routine startup (Figures 1 and 2). Shortly afterwards, the

monitoring system detected a bearing fault on the same

middle bearing of another liquid expander on a different

train. In fact, the same fault was then also detected by

the monitoring system within the same time period at an

entirely different LNG plant. A diagnostic specialist was

called in from the monitoring system provider to do a root

cause analysis with the customer. After looking at the data,

it was determined that the premature failure of the bearings

was caused by a recent change in the startup sequence of

the machines.

The importance of startup

Startup is critical for a liquid expander, since the bearings

have to be precooled prior to operation. At ambient

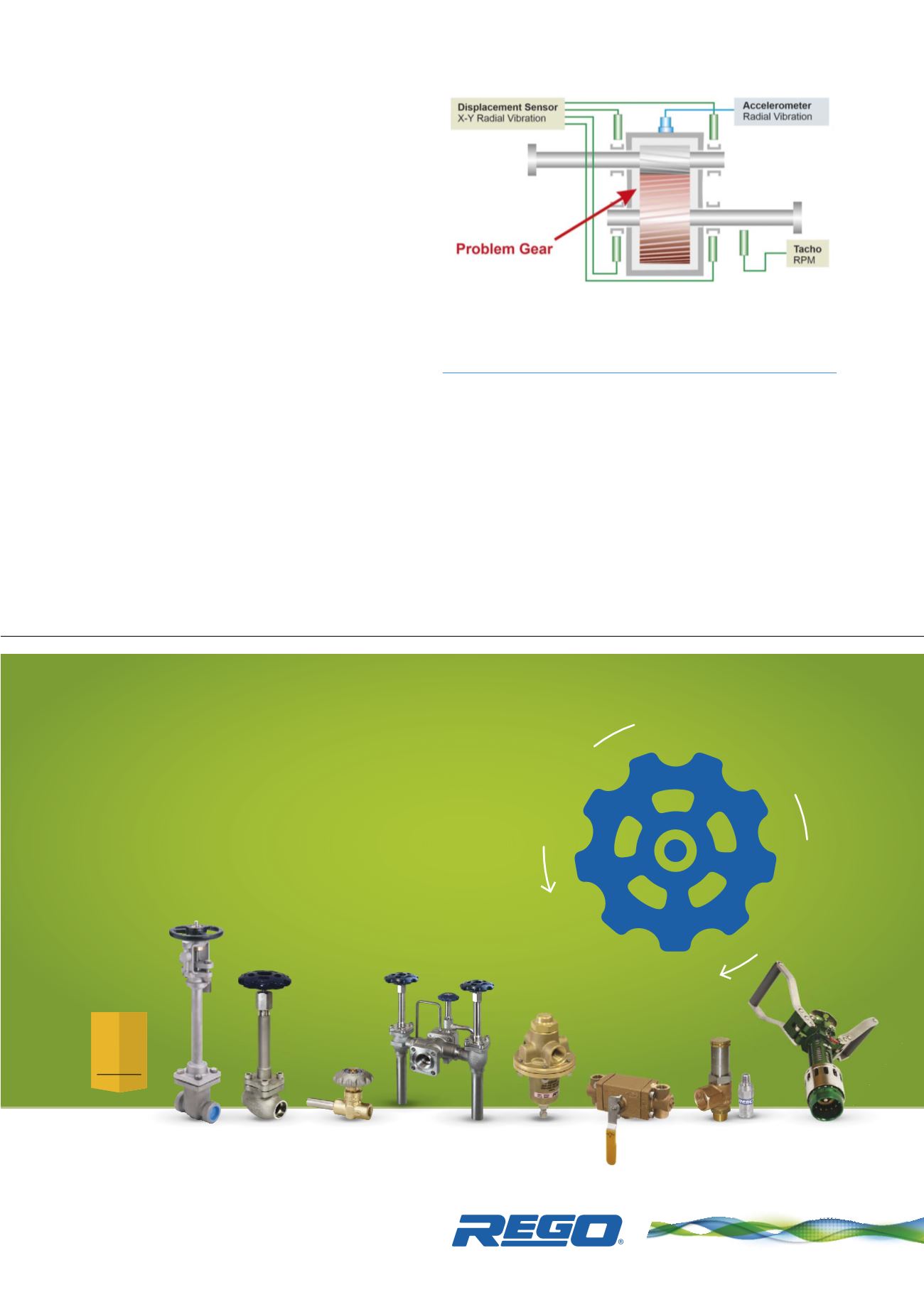

Figure 3.

Vibration sensor configuration of the propane

compressor gearbox. The gear where high vibration was detected is

shown in red.

10

REGO

YEAR

WARRANTY

For more than 110 years RegO

®

has been building a

complete line of expertly designed, long-lasting gas

& liquid flow and control solutions backed by the

industry’s best technical and sales support.

See the complete line at

regoproducts.com/lng +1 336.449.7707eŔɽ ˫ȶˁ ŔȥƎ ƃȶȥʋɭȶȍ ɽǫȟɢȍǫ˪ơƎࡳ

S

O

L

U

T

I

O

N

S

C

H

A

L

L

E

N

G

E

S

*Industry-standard 18 month warranty

MANIFOLDS

RELIEF

VALVES

REGULATORS

LIQUID

CYLINDER

VALVES

GLOBE

VALVES

GODDARD

GATE

VALVES

DIVERTERS

LNG FUELING

NOZZLES

*