38

April 2020

thermodynamically efficient, which will result in lower

operating costs. The downside to this, however, is that

actions such as this can sometimes be undertaken at the

expense of adding additional equipment and complexity to

production. This will also have to be monitored. In other

areas, the production trains are becoming larger, which

results in lower production cost. Nevertheless, in this case

the cost of downtime becomes more expensive if the train

is unexpectedly down. Ultimately, the benefits of developing

technology in either case become much more significant if

the risks can be mitigated.

Regardless of the chosen course of development,

machine condition monitoring will play an even more

important role in ensuring uninterrupted reliable production

in future scenarios. Performance monitoring of machines is

already standard practice for many existing machines and

larger machine sizes present no monitoring obstacles.

Condition monitoring is already geared for these and other

future development requirements, based on past experience

of successfully dealing

with existing operation

and maintenance

challenges.

Asset

healthcare

challenges

today

Machines in an LNG plant,

especially those involved

in the liquefaction process,

are subject to extreme

operating conditions. The

thermal expansion of a

refrigerant compressor,

pump or liquid expander

between startup and full production at cryogenic

temperatures is intense, thereby subjecting the bearings

and other machine components to severe loads during

startup and shutdown. Even small variations in the

process can have significant effects on the overall

loading of the machines. As many machines are

operated at variable speeds and loads, this basically

renders calculated mean-time-before-failure values

for the machine components to spread out and be

unpredictable.

As in many other sectors of the petrochemical

industry, ensuring the reliable operation of these

machines is not a trivial task – especially when

considering the reduced numbers of maintenance staff

and specialists onsite at plants, and the increasingly

competitive nature of the industry.

Condition monitoring solutions

are evolving

Very few people in the LNG industry dispute the merits

of effective condition monitoring, but there is a wide

disparity on what constitutes an effective monitoring

solution. Some simply continue to use their legacy

system without being aware that condition monitoring

technology itself has evolved over the years.

However, it is now possible to detect developing

symptoms from a wider range of potential failure modes

earlier and more reliably than 10 years previously. In a

similar fashion, diagnostics have become more accurate in

assessing fault severity and establishing the need for

maintenance action within an accurate timeframe.

Advancing data science technology enables process data to

be more readily correlated with fault monitoring data, so

that diagnostics and root cause analysis can be performed

faster and more accurately. Automatic fault prognostics and

decision support become a reality after many years of

monitoring data has been accumulated and can now be

analysed by artificial intelligence (AI) and machine learning

(ML).

Case studies

Current condition monitoring technology provides early

healthcare awareness for all the critical machines and

much of the balance-of-plant to reduce downtime and

maintenance costs, while at the same time avoiding

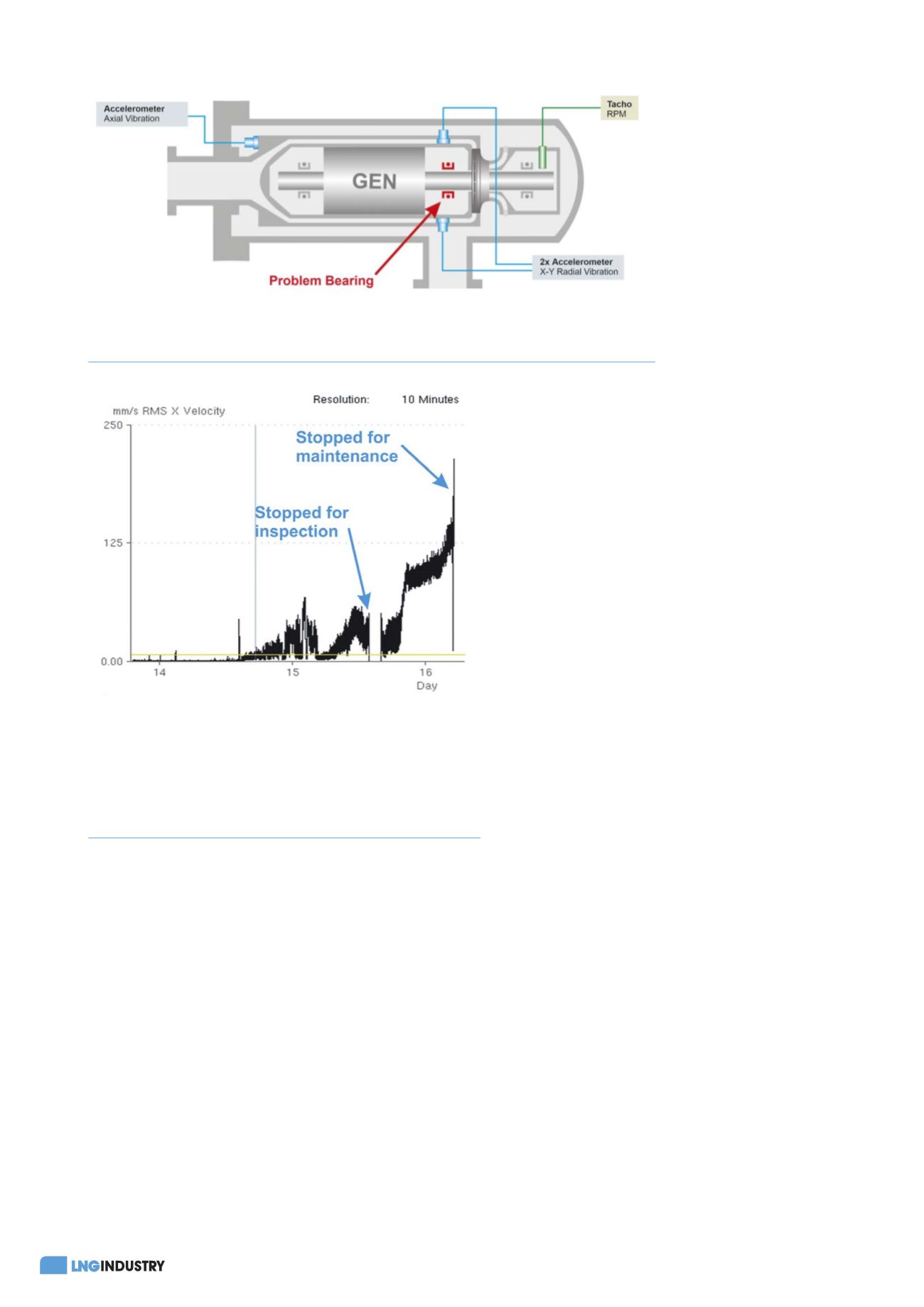

Figure 1.

Vibration sensor configuration of the liquid expander. The bearing where high

vibration was detected is shown in red.

Figure 2.

The vibration trend progressively increased after two

startups, so the liquid expander was shutdown for inspection. No

damage was found so it was started up again, but the vibration

continued to increase. Finally, it was shutdown for maintenance

and this time it was observed that the bearings showed signs of

damage.