April 2020

2

9The rupture disc manufacturer can

work together with the design or process

engineers to select the rupture disc

which gives the best possible

performance for a specific process. Too

often, engineers underestimate the

importance of carefully considering this

safety critical device. Since the cost

investment in rupture discs is often less

significant than other instrumentation,

they can be seen as a commodity and not

given the attention they require. The

majority of spurious failures from rupture

discs can be avoided by working together

with the disc manufacturer to select the

ideal rupture disc for the process conditions.

Case study: rupture discs in an

LNG plant

Rupture discs can also be used in front of safety valves to

allow for regular in-situ testing. This reduces the need for

removal of the safety valves for extensive maintenance, which

can be particularly useful in corrosive environments.

Regasification plants are often located close to the LNG

terminal and, therefore, in a coastal environment. Such is the

case in a large European LNG terminal where REMBE rupture

discs are used to protect the safety valves and reduce

emissions. Such corrosive environments can make the

selection of the materials of construction for safety devices

extremely difficult. The tried and tested method of valve

maintenance is regular removal and replacement of the valve,

but operators want to minimise the maintenance schedules of

their processes in order to maximise uptime without

compromising on safety.

The use of REMBE KUB V series rupture discs allows for

in-situ lift testing of the safety valves to ensure that they are

still operational without having to remove them.

Additional benefits in lower costs can also be realised as

REMBE rupture discs can be removed, inspected and reused if

still in serviceable condition, while other rupture disc

manufacturers require the replacement of their disc when

they need inspection as they cannot be re-installed.

Overall, the use of rupture discs in combination with

safety valves presents a safe and cost-effective solution to

meet challenging emission requirements for LNG processes,

and at the same time maximising output by minimising

downtime of the plant.

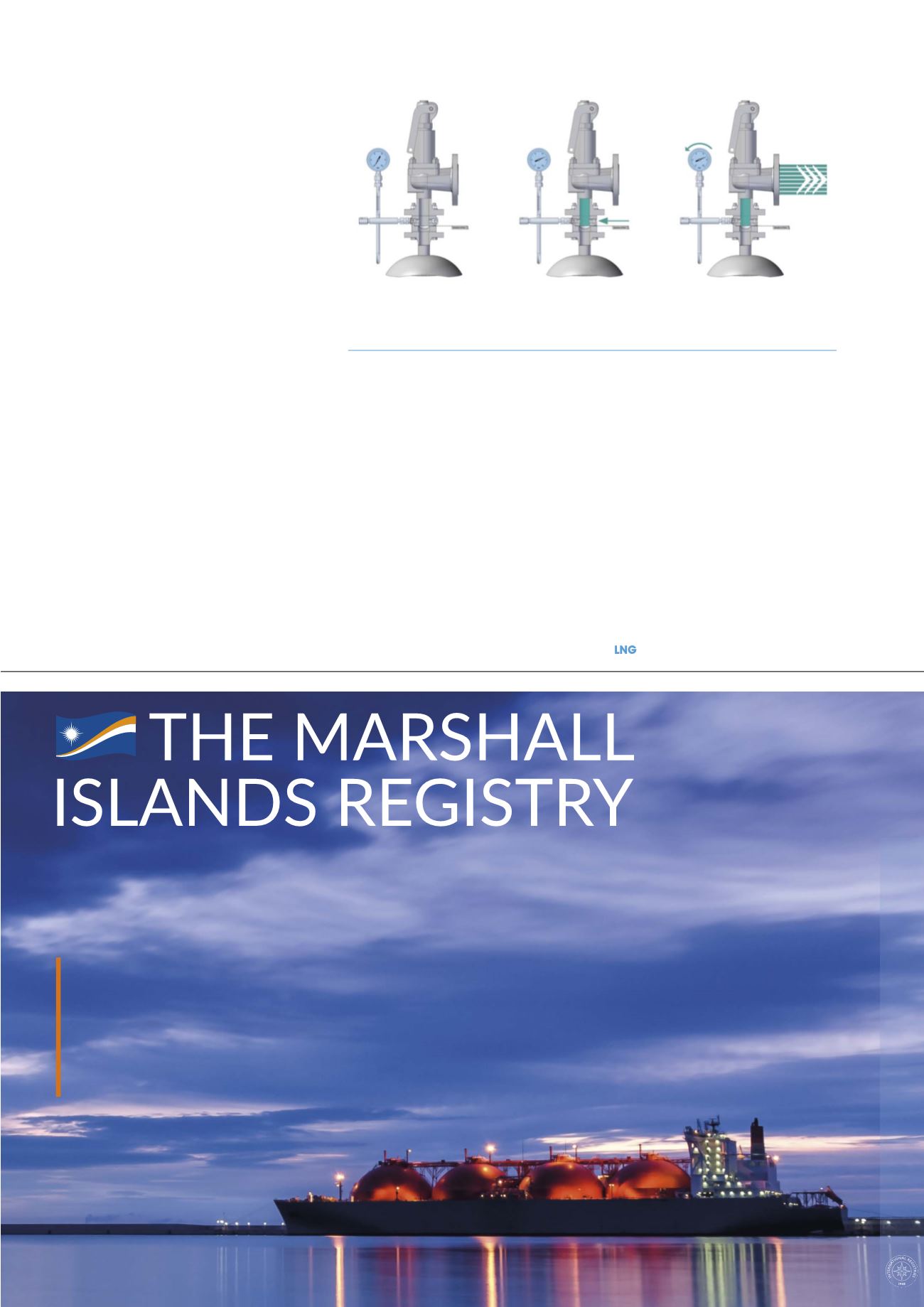

Figure 3.

In-situ test in order to test whether the safety valve is functioning

correctly.

m|;um-ঞom-Ѵ !;]bv|ub;vķ m1ĺ

bm -LѴb-ঞom b|_ |_; -uv_-ѴѴ vѴ-m7v -ubঞl; ş ourou-|; 7lbmbv|u-|ouv

blog.register-iri.com www.register-iri.com houston@register-iri.comSTEADFAST

QUALITY

UNMATCHED

SERVICE

$_; -uv_-ѴѴ vѴ-m7v !;]bv|u 1omvbv|;m|Ѵ

r;u=oulvĺ $_; u;1ou7 vr;-hv =ou b|v;Ѵ=ĺ

_oov; |o Y |_; ouѴ7Ľv Ѵo1-Ѵ Y-]ĺ