28

April 2020

the requirements visualised for future zero targets. No safety

valve is 100% leak-tight and they struggle to meet the

exacting requirements of the legislators. An alternative

solution is needed.

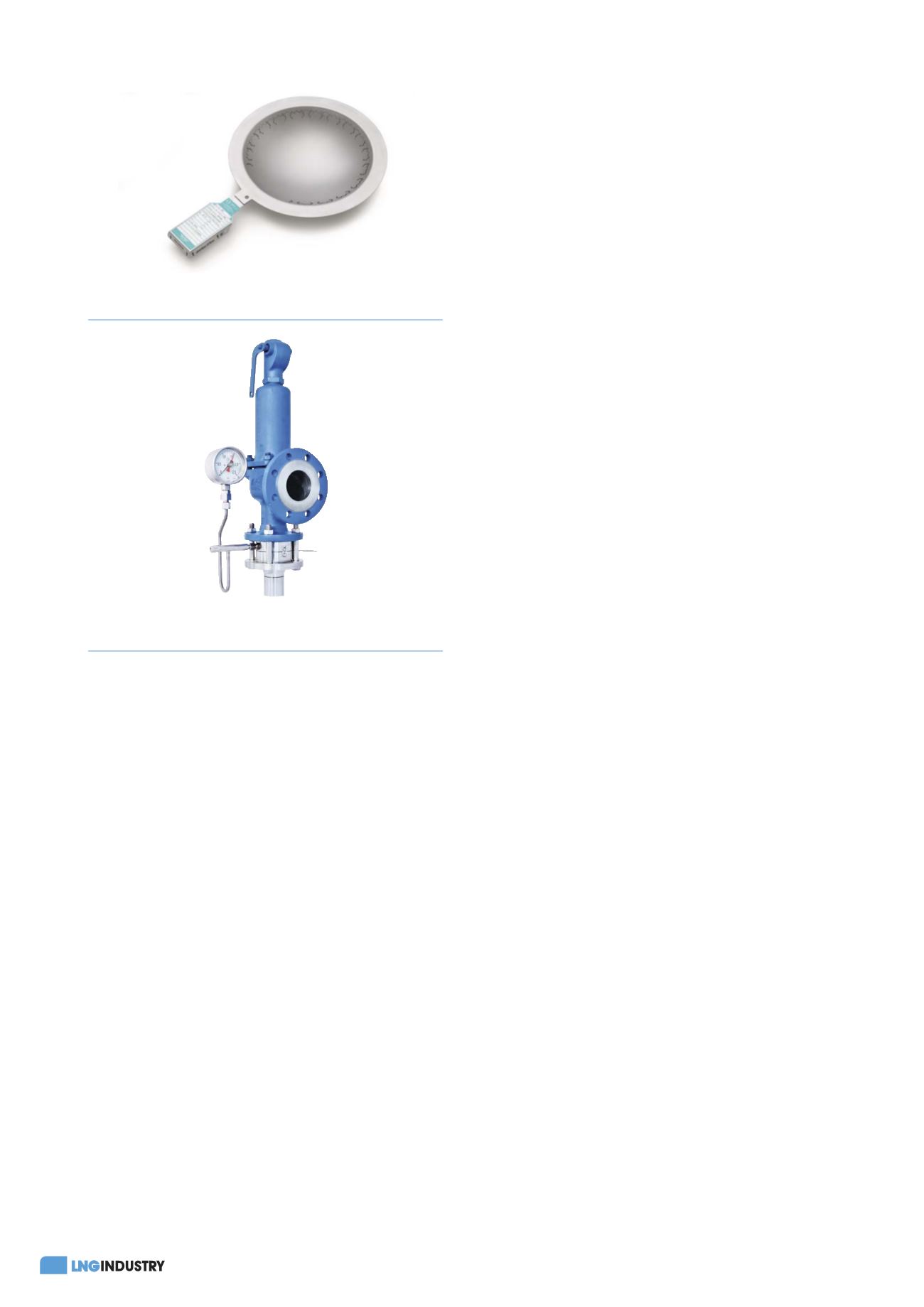

Rupture discs: an

underappreciated safety device?

Although rupture discs have been around for several decades,

they have often been considered to be nothing more than

a secondary solution to be used where there is a chance

that the safety valves may fail and lead to a dangerous

overpressure. Some might say they are a poor relation to the

safety valve, which is a title they certainly do not deserve. The

lack of understanding of the rupture disc amongst engineers

and operators who install and maintain them continues to

this day and results in a number of myths around rupture

discs which are passed on from generation to generation.

It is often perceived that the disc is a ‘problem’ when it

opens and lets the pressure out. Due to the fact that rupture

discs do not reclose, every disc activation results in a process

stop while the cause of the problem is identified and the disc

is replaced. This nuisance downtime leads many operators to

associate rupture discs as a ‘problem’. In fact, opening is

exactly what the rupture disc is designed to do. It is still

unrecognised by many operators that, when the disc performs

correctly, it is not the problem, but the solution.

So how can the rupture disc help the safety valve perform

better in use? Rupture discs are 100% leak-tight. Therefore, by

installing a rupture disc in front of a safety valve, you get a

solution which can meet emission requirements. This has

been a common solution for a number of years to meet strict

legislative requirements.

The belief that this arrangement adds more cost into a

project has been proven to be false. In fact, the opposite is the

case; costs come down. Plant managers are now beginning to

appreciate that a properly engineered rupture disc will help

lower operating costs and increase the up-time for a plant.

In a typical installation, a safety valve may be in contact

with a process with a high concentration of corrosive media,

increased temperatures and an operating pressure close to

the safety valve set pressure. This tests the limits of safety

valves, and we see poor performance below the expected

levels needed for operational stability and no leaks. High

maintenance costs are needed to keep the valve as close to

the original specifications as possible, increased downtime to

the production for routine valve servicing and/or repairs, and

higher manpower costs to cover the work scopes.

Reduction in CAPEX

The solution provided by safety valve manufacturers is a

higher specification valve, more exotic materials with higher

CAPEX costs, and increased cost of spares to maintain the

valves. Consider a typical petrochemical plant with several

hundred safety valves. The CAPEX mounts up to be a

significant increase in the cost of the valve inventory.

A rupture disc installed upstream of the safety valve, in a

material that withstands the process conditions, isolates the

valve from the process and permits the plant owner to install

a safety valve in lower grade materials, whilst still meeting all

the requirements of the design, but with significant reduction

in the safety valve CAPEX.

The rupture disc and holder will be a minor cost

compared to the exotic or higher specification safety valve

and, if you also consider the lower maintenance costs, the disc

and holder costs nothing. In fact, you are on a win-win path

with greater production uptime, fewer emissions and greater

safety, as well as overall lower maintenance costs and a

smaller spares inventory.

However, there are still examples of safety valves,

protected by a rupture disc upstream, failing, needing

maintenance and stopping production or causing safety issues.

The protection of safety valves with rupture discs has

become increasingly common in recent years across several

industries. However, many operators miss the opportunity to

fully protect the safety valve by also isolating the valve from

potential corrosive elements on the outlet side of the valve.

In many cases, the valve outlet is not a separate discharge

line, but is connected to other parts of the plant via a

manifold which allows process gases/vapour to enter the

outlet of the valve. If there is a risk that the process media

can damage the valve via the inlet, this is also the case

downstream and this is what causes such failures.

This is something easily eliminated by isolating the safety

valve outlet via rupture disc to prevent any contact with the

process media. The rupture disc will also block any back

pressure from entering the safety valve and remove those

concerns during valve selection.

With burst sensors installed both upstream and

downstream, rupture discs can be monitored and connected

back to the control room for system reporting across the plant

so operators know instantly which valves and discs are in a

green or red state.

Figure 1.

Rupture disc for isolating safety valves.

Figure 2.

Ideal combination – safety valve and rupture disc.