32

April 2020

use of very large gas compressors. For the best utilisation of

cargo, large compressors ranging from 10 to 70 MW are used

to compress gas to 1/600

th

of its initial volume.

Many of the large LNG compressors in use today are

driven by gas turbines. These offer acceptable reliability, as

well as the convenience of using some of the gas being

compressed as a fuel source. However, burning gas as fuel

releases nitrogen oxides (NO

x

)

–

a family of poisonous, highly

reactive gases known to cause asthma.

2

This

hazard presented by NO

x

prompted the US

Environmental Protection Agency (EPA), on 6 April

2018, to retain, without revision, the current

national ambient air quality standards (NAAQS) for

oxides of nitrogen.

2

Taking this into account, large

capacity electric motors, powered by variable

frequency drives (VFDs), can offer a solution to

help localities to reduce NO

x

concentrations, and

to manage their compliance with emissions and

environmental regulations. Indeed, the primary

benefit of electric motor-VFD systems is that they can be used

to drive large compressors without directly burning fuel.

More uptime and higher

efficiency

The facts above and the steady development of power

semiconductors have revealed the advantages of using

the electric motor-VFD system. For example, an electric

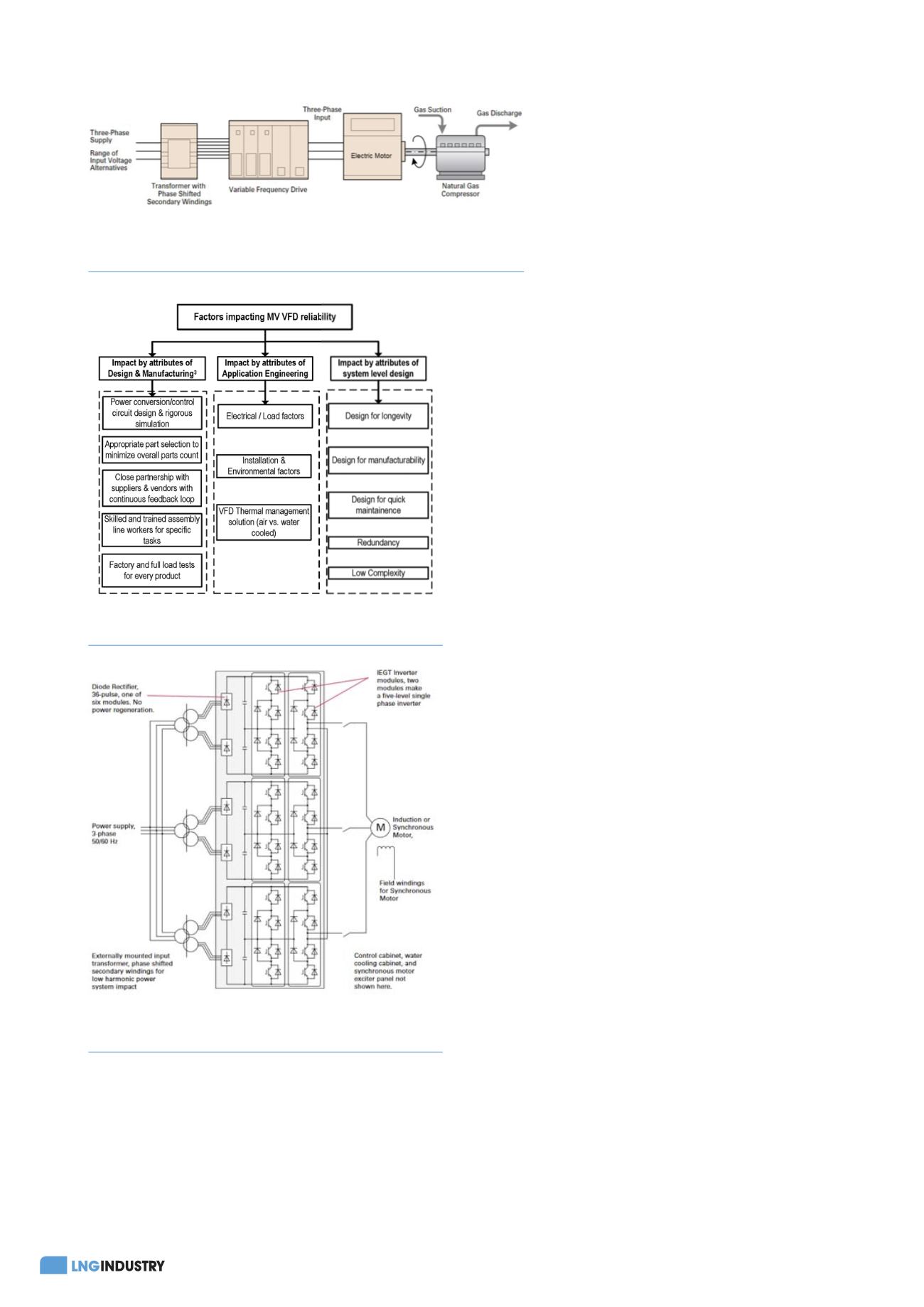

motor-VFD system, as depicted in Figure 1, permits controlling

flow and pressure through speed control and can improve

the power factor of the power supply. Concerns with regards

to harmonics have been addressed with proper isolation

transformers and by the continuous development of VFD

technology.

As with all new technology, or a new application of an

existing technology, some operators are cautious about using

the electric options of a motor-VFD system. Most reservations

about the use of electronic apparatus and VFDs have origins

in bad experiences caused by procurement decisions,

misapplications and maintenance difficulties due to the

intrinsic quality of the VFD. Conversations often start with the

question, “how reliable is the VFD?”, and, naturally, the

invoking of the word ‘reliable’ elicits many responses. The two

most relevant questions are whether the system can operate

uninterrupted between planned shutdowns, and, in the case of

unplanned maintenance, how soon the system can return to

production? These concerns are swiftly put to rest by a

comparison of the upside and perfomance of the motor-VFD

system with that of a gas turbine.

A motor-VFD system provides more uptime than a gas

turbine, thus it is less expensive to own. Furthermore, a

motor-VFD system boasts superior efficiency compared to a

gas turbine: 97% versus 20 – 40%, respectively, depending on

the load and temperature.

4

Table 1 shows some quick cost

comparisons of a gas turbine and an electric motor-VFD. The

comparisons do not reflect the costs with precision, but they

are effective in highlighting the proportions.

In terms of LNG production, unplanned and long

interruptions can cause losses of thousands of dollars per

hour, not only due to maintenance costs, but due to loss of

revenues at a rate of US$1 million per day.

5

Reliability is defined as the probability that a product or

service will operate properly during its lifespan, under

intended operating conditions. It must be intrinsically

designed into the product (in this case, into the VFD).

6

At the

design stage, in the name of ‘building-in’ reliability, significant

effort is expended to ensure longevity, manufacturability and

ease of operation and repair.

Besides the intrinsic quality of the design, the

manufacturing practices and the correct application of the

VFD are also determinants of reliability (as summarised in

Figure 2.

Factors determining the reliability of large VFDs.

Figure 1.

High power motor variable frequency drive (VFD) system driving

an LNG compressor.

Figure 3.

Configuration of a VFD using a small number of

silicon devices.