26

LNG

INDUSTRY

MARCH

2016

Quickly introducing large increases in capacity and

technology remains problematic for the LNG industry as it must,

at all costs, deliver the LNG product to contracted buyers.

Therefore, repeatability is the first choice means of improving

project economics. Repeat designs mean negligible project risk

in execution and operation, schedule gains through the reuse of

engineering, and the optimisation of the construction sequence.

The founding principle of the long-term (generic) gFLNG Master

Agreement – entered into in 2009 between Shell and the

Technip Samsung Heavy Industries Consortium (TSC) – is to

enjoy repeatability gains with multiple orders over an extended

period. This approach offers a predictable and repeatable

project model that facilitates investment decisions.

The Browse joint venture (JV) has announced its proposal to

develop resources in the Browse Basin, Australia, through an

FLNG concept. This is based on the deployment of three FLNG

facilities. The design of the proposed Browse FLNG facilities will

be predominantly the same as for the Shell

Prelude

FLNG

project, with minor modifications required due to the different

characteristics and water depth at the location of the Browse

reservoirs.

Innovation

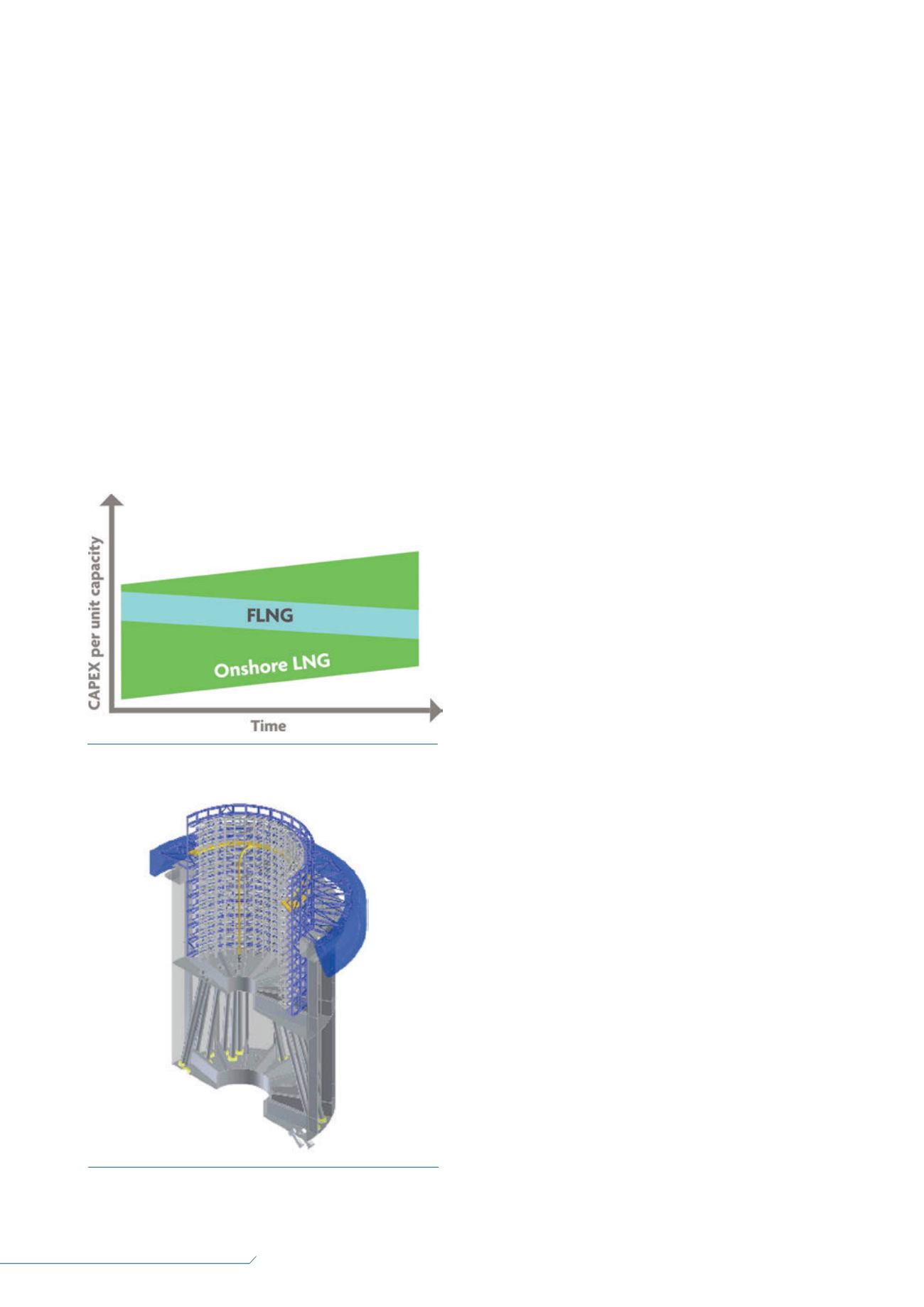

FLNG is at an entirely different juncture to the mature area of

onshore LNG. It is new and ripe for further innovation. There is a

clear opportunity for FLNG to have its place among the lowest

cost solutions available to owners of offshore gas reserves,

enabling projects to go ahead while meeting the expectation of

lower delivered LNG prices.

The initial projects went ahead, sometimes using

conservative choices for processes, equipment or layout

whenever reliability or safety could not be guaranteed based on

what was known at the time. The feedback from execution

enables good solutions to be maintained and alternatives to be

found when problems in engineering, procurement or

construction (EPC) have been evidenced. Above all, there is the

possibility of targeting a substantial increase in the output of

LNG and other hydrocarbon products.

Shell has described the Lean FLNG concept, whereby LNG

production is increased from fields that do not benefit from the

coproduction of LPG and hydrocarbon condensate.

1

This trend to larger production rates is further reflected in

the plans announced for the ExxonMobil facility planned for

Scarborough, offshore Australia.

2

The large capacity is justified

by the size and quality of gas reserves.

Production intensification

This implies producing more product from the same offshore

structure. A reasonable target is 8 million tpy of LNG, as this

is effectively proven onshore. Increasing production requires

attention to all areas of the FLNG platform, either to increase

the capacity of each unit, or to free up deck space that can be

used to increase liquefaction capacity.

Feed gas

Bringing substantially more than 1 billion ft

3

/d of wellhead gas

onto a weathervaning floating production facility is a novelty.

One alternative is to spread moor the FLNG facility by designing

for increased deck movement or by adopting heading tolerant

hull designs.

If a turret with weathervaning for heading control is

desirable, then the following solutions can be used:

Mechanical swivel stacks, although there may be some

development needed to improve fluid flow capacity, fluid

pressure and power handling capability.

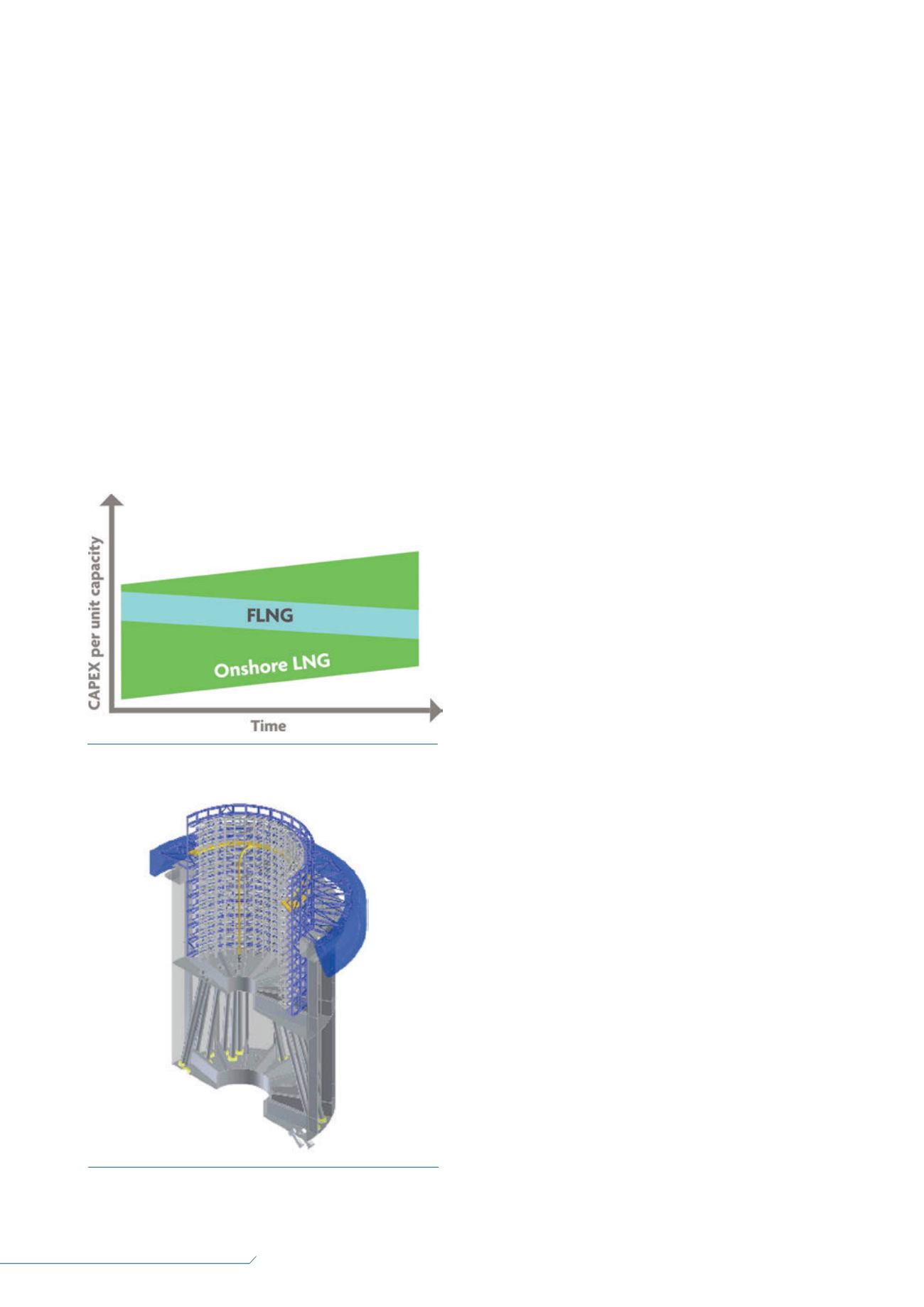

Technip’s Spiral Swivel Stack (SST) is a solution with a

coiled flexible pipe, offering high capacity and intrinsic

safety through flanged joints with no dynamic seals. Risers,

electrical cables and control lines enjoy an unbroken

connection from the deck to the subsea equipment on the

seabed.

Process technology

Pretreatment

Methods for the intensification of acid gas removal, dehydration

and heavy hydrocarbon removal have all been described, but

can be studied and developed in the new context of FLNG.

Liquefaction

The natural gas liquefaction process best suited to high

capacities offshore is the dual mixed refrigerant (DMR) process.

Figure 3.

Technip’s Spiral Swivel Stack (SST).

Figure 2.

FLNG will be increasingly attractive thanks to scale,

replication and innovation.