18

LNG

INDUSTRY

MARCH

2016

requirements for a large section of the FLNG facility and

will have a great impact on the overall vessel design.

There are a number of liquefaction process cycles that

are suitable for FLNG application.

1

These include the

AP-SMR

TM

single mixed refrigerant process, the AP-DMR

TM

dual mixed refrigerant process and the AP-N

TM

nitrogen

recycle process. Some key features of these processes are

summarised in Table 1. The AP-SMR and AP-DMR

processes utilise hydrocarbon refrigerants and have been

presented previously in

LNG Industry

.

2

Comparing liquefaction

processes: cooling curves

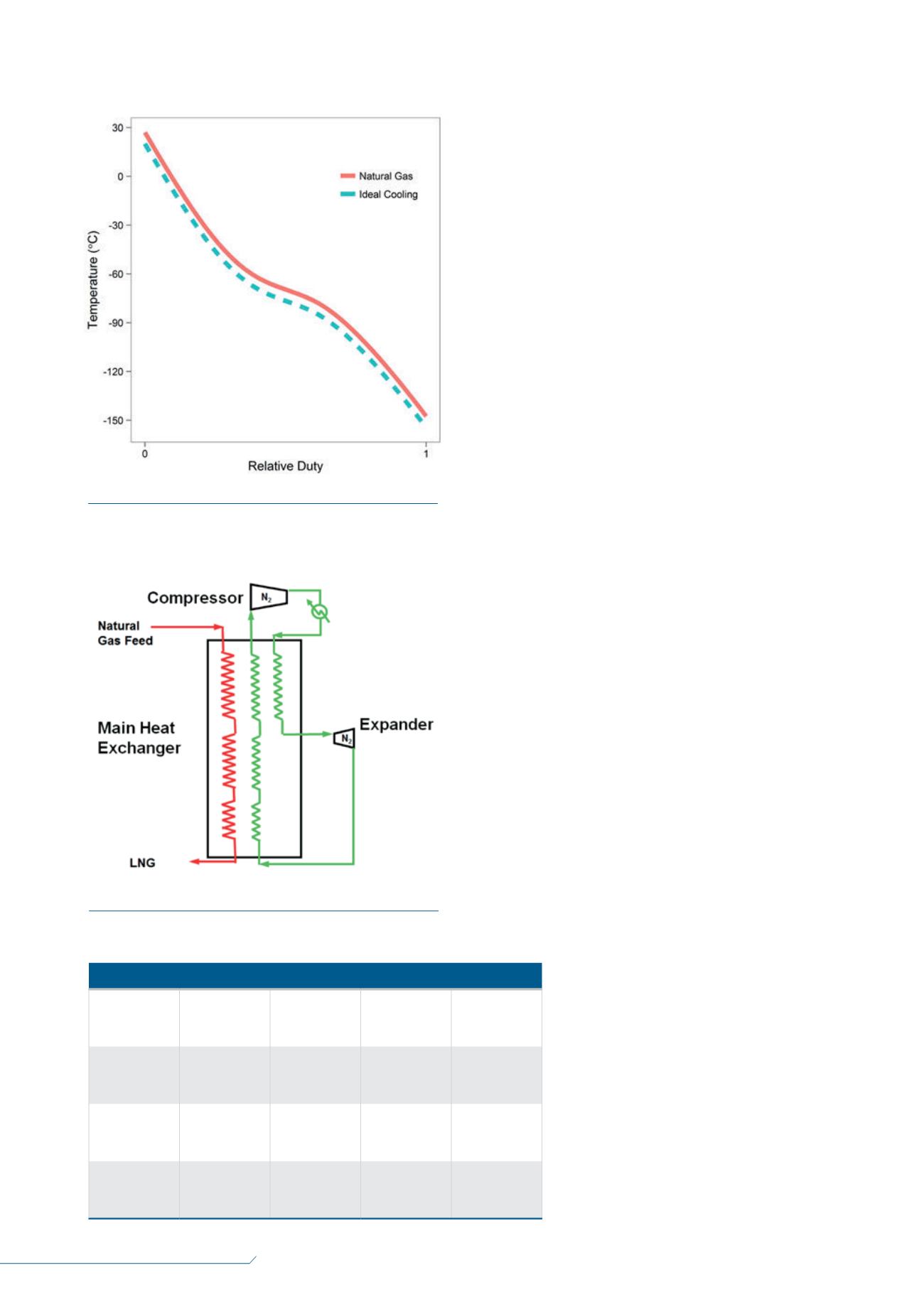

Process engineers often use cooling curves as one

measure to optimise and compare liquefaction processes.

An ideal cooling curve is given in Figure 1. The horizontal

axis for this plot is the fractional amount of duty removed

from the natural gas. The vertical axis is the temperature

of the process stream. In Figure 1, the feed stream is

the hot side; the natural gas stream and its temperature

is shown by the red solid line. The refrigerant stream

temperature, which is the cold side of the main exchanger,

is shown by the blue dashed line.

For the process given in this example, the natural gas

enters the exchanger as a gas at ambient temperature. At

first, sensible heat is removed from the natural gas and

the resulting cooling curve is relatively straight and the

slope is proportional to the heat capacity of the feed gas.

After the dew point is reached, the slope flattens and the

feed liquefies as latent heat is removed from the natural

gas. Once liquefied, the change in natural gas

temperature increases as sensible heat is removed to

subcool the LNG.

The blue dashed line is an ideal cooling curve for an

ideal refrigerant system, or combination of systems. It is

considered as ideal because the shape of the curve closely

follows that of the natural gas cooling curve. The

temperature difference between these two curves are

related to the efficiency of the process. For a given

liquefaction process, the closer these curves are to each

other, the more efficiently refrigeration is supplied to the

natural gas, reducing the refrigerant compression power

requirement. Also, the closer these curves are to each

other, the more heat exchanger surface area is needed. For

a given process, the optimal heat exchange surface area

and compression power is determined by

the project specifics and the trade-off

between CAPEX and OPEX.

Cooling curves can also be used as an

aid in liquefaction cycle development by

identifying areas for improvement, and to

compare liquefaction cycles.

Nitrogen recycle

expander process

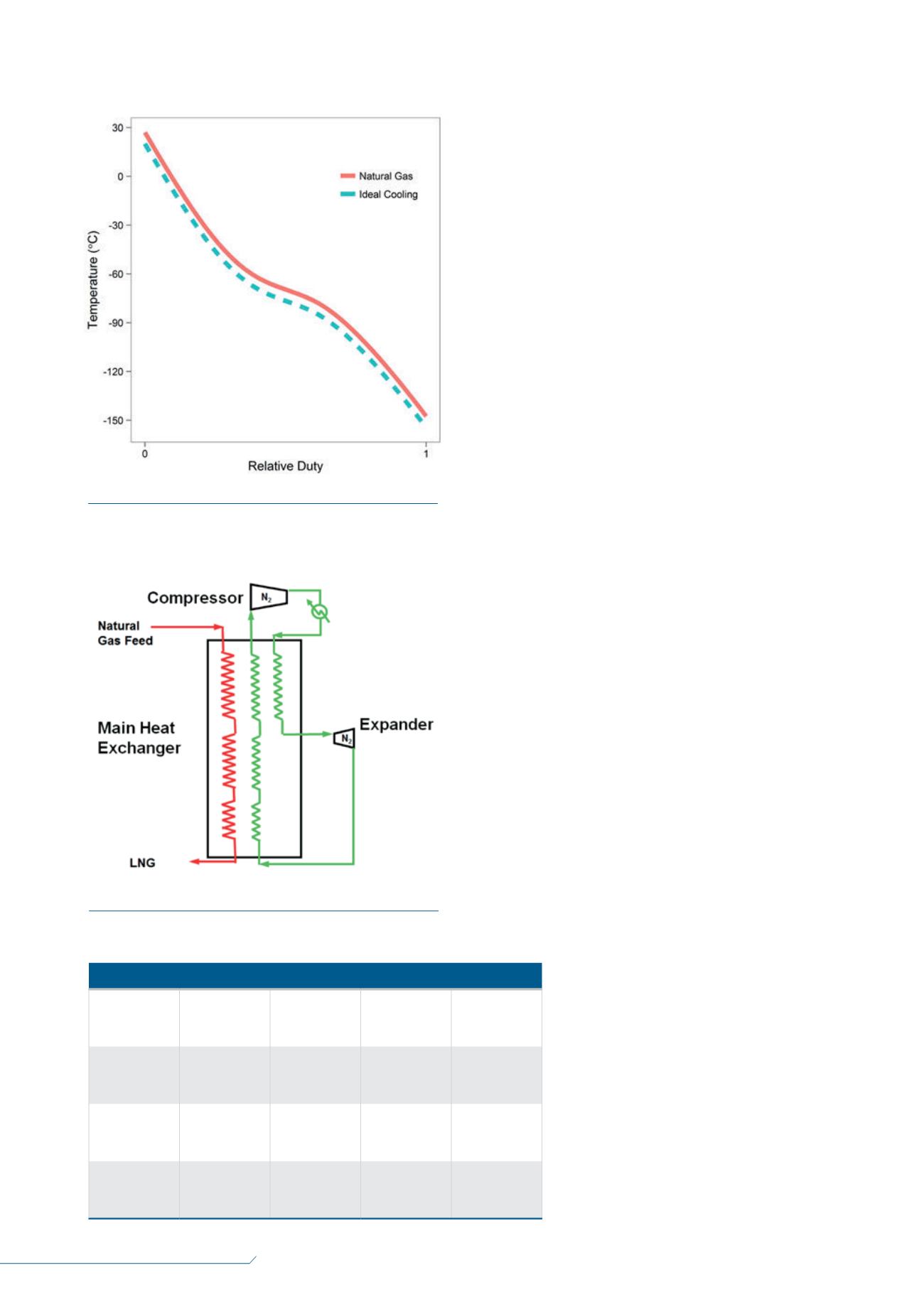

The nitrogen recycle expander process

is based on a Brayton refrigeration cycle,

which uses gaseous nitrogen as refrigerant.

The simplest nitrogen expander cycle has

only one expander, as shown in Figure 2.

In this process, nitrogen is compressed to

Table 1.

Air Products’ natural gas liquefaction processes for FLNG applications

Process

Relative

efficiency

FLNG train

capacity

(million tpy)

Type of

refrigerant

Feature

AP-DMR

1

3

–

4

Boiling

hydrocarbon

mixture

High capacity

AP-SMR

0.88

<2

Boiling

hydrocarbon

mixture

Simple layout

AP-N

0.72

<2

Gaseous N

2

Non-flammable

refrigerant

Figure 1.

Ideal cooling curve.

Figure 2.

Standard nitrogen cycle.