20

LNG

INDUSTRY

MARCH

2016

high pressure and heat is rejected into the atmosphere

through the compressor intercoolers and aftercooler.

The refrigerant is further cooled in the main cryogenic

heat exchanger (MCHE) and then expanded to cryogenic

temperature in a turboexpander. Once expanded, the

nitrogen enters the cold side of the MCHE, where it

precools, liquefies and subcools the feed, as well as

initially cools the warm nitrogen. After leaving the MCHE,

the low pressure refrigerant returns to the compressor

suction.

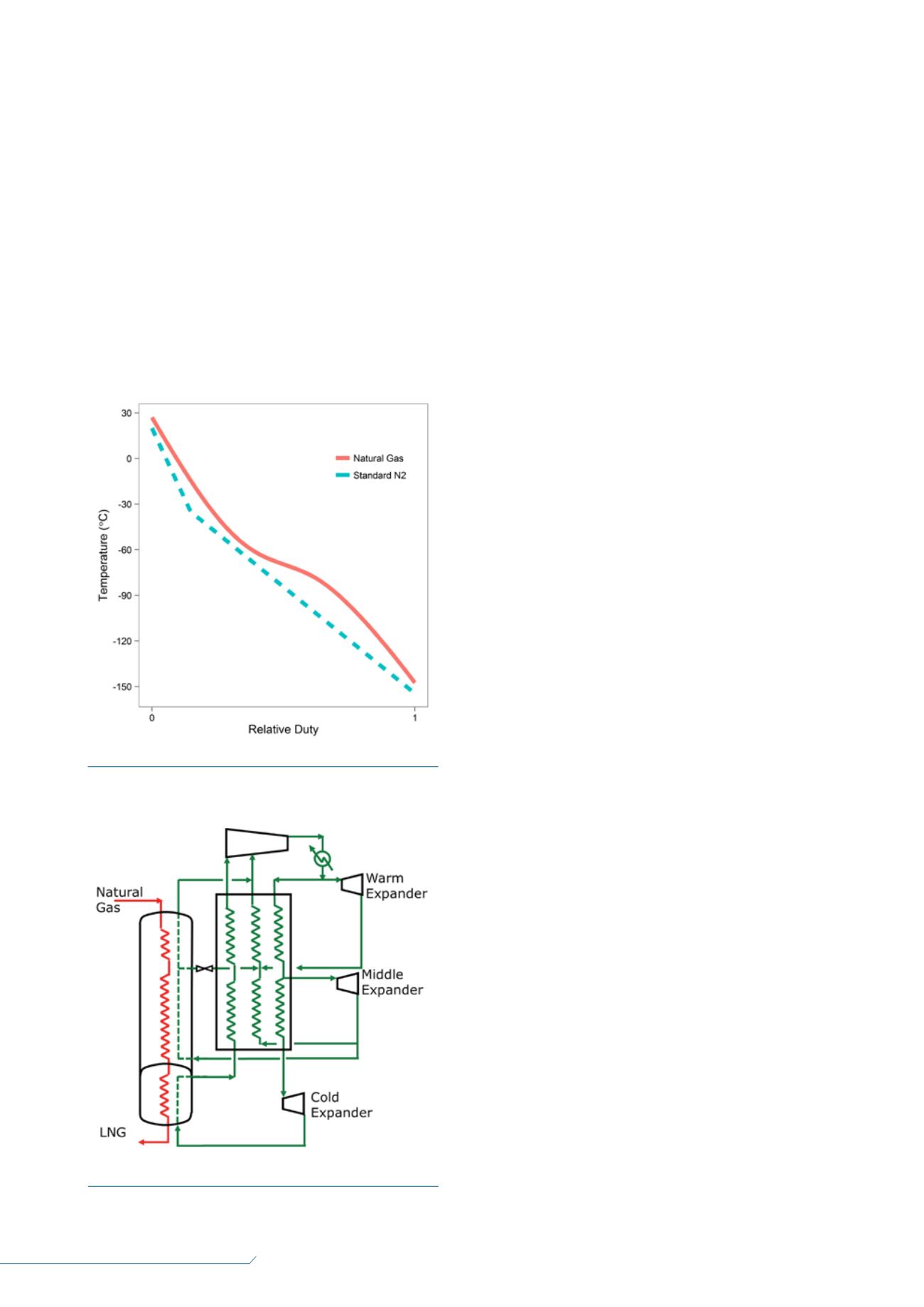

The cooling curves for this process are given in

Figure 3. In this figure, the hot side temperature, shown in

red, is the temperature of the natural gas feed as it is

precooled, liquefied and subcooled. The curvature in

temperature line is due to the latent heat removal from the

condensing mixture. The temperature profile for the

nitrogen, cold side, is straight without any curvature. This

is because warming of the cold nitrogen vapour is all

sensible heat as there is no phase change.

The bend in the nitrogen line is where the ‘hot side’

nitrogen exits the main exchanger and enters the

expander. Notice that the difference between these two

cooling curves changes through the exchanger. The larger

gaps show that there is underutilised refrigerant, which

translates to inefficiencies in the process or, conversely,

represents room for process improvements.

This standard process is simple with minimal

equipment. It is often used in small plants, such as peak

shavers where the production is only a few hundred tons

per day.

3

However, as this process is scaled up to

capacities relevant for FLNG, it becomes less simple, since

the expander duty will increase to the point where

multiple units in parallel will be needed, as well as their

associated piping. In addition, the number of brazed

aluminium heat exchangers will increase such that

multiple cold boxes and the associated piping will be

required.

Another factor to be considered is thermal stresses on

the heat exchange equipment. The cold side of the

exchanger will have cryogenic liquid and the hot side will

have cryogenic vapour. During upset conditions it will be

quite easy to get an imbalance in duty, creating large

thermal gradients in the exchanger because the refrigerant

flow is independent of the natural gas feed flow. The

likelihood of these gradients occurring also increases with

the size of the piping system and number of cores and

cold boxes in parallel. Coil wound heat exchangers have

years of operating experience, demonstrating that they

can withstand these stresses. In addition, the process tube

bundles in the coil wound heat exchanger are enclosed

within a pressure vessel shell, providing an additional

level of containment in the unlikely event of a leak due to

maloperation.

Case study

Two FLNG projects that are in construction,

Petronas FLNG

Satu

and Petronas FLNG

Dua

, will use the

AP-N liquefaction process.

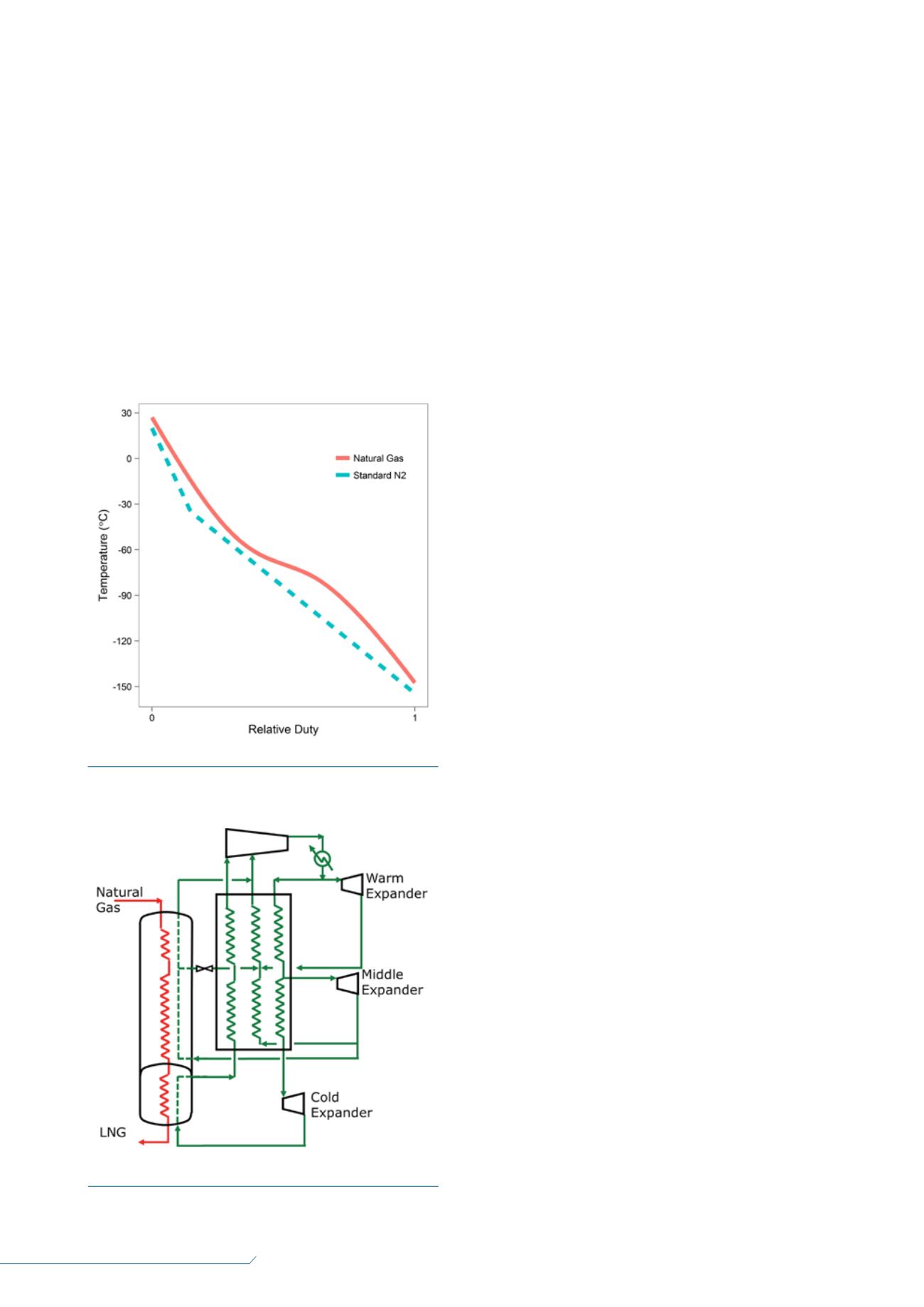

For these large capacity liquefiers, the patented AP-N

liquefaction process

4

takes advantage of the multiple

expanders required and coil wound exchangers to improve

the robustness and efficiency of the process for FLNG

service. As shown in Figure 4, the natural gas, shown in

red, is liquefied in a coil wound exchanger. The gas is

precooled in the top section (often termed ‘bundle’),

liquefied in the middle section and, lastly, subcooled in

the bottom section. Those familiar with the use of coil

wound heat exchangers in land-based mixed refrigerant

(MR) cycle plants will notice that the coil wound heat

exchangers for the N2 cycle are ‘cold end down’ rather

than the typical ‘cold end up’ configuration. This is

because the refrigerant, being all vapour, does not need to

make use of gravity as in processes where the warmed

refrigerant condenses to a liquid. The nitrogen economiser,

which has nitrogen vapour on both the hot side and cold

side, can be brazed aluminium exchangers, since the fluids

Figure 3.

Cooling curves for standard nitrogen cycle.

Figure 4.

AP-N liquefaction process.