28

LNG

INDUSTRY

MARCH

2016

Investment in new fabrication facilities for the coil wound

exchangers used in the precooling cycle and as the main

liquefier has effectively removed previous limits.

Refrigerant compressors and drivers

Over five decades, the LNG industry has seen constant

innovation to increase capacity and improve efficiency, despite

a culture of risk aversion. The onshore LNG business has done

this through landmark projects.

The main step changes in capacity have come with the

introduction of new machinery, such as the following:

GE Frame 5 gas turbines in the 1980s led to the

abandonment of steam turbines.

The introduction of the GE Frame 7 in the early 1990s saw a

threefold increase in gas turbine shaft power.

10 years ago, the GE Frame 9 for the AP-X trains in Qatar

raised shaft power by another 50%.

New high power output marinised gas turbines are the key

to high capacity FLNG. Such machines should ideally also have

high availability, be lightweight and offer high efficiency,

although these may be secondary considerations. Several

manufacturers have new machinery solutions operating

onshore, sometimes in power generation service. Given the

LNG industry’s track record in qualifying new machinery, these

gas turbines are likely to be available for the next generation of

projects.

Layout

Process schemes and equipment selection need to be

reviewed again, with a view to identifying opportunities for

intensification.

Improvements in risk-based modelling results in more

efficient safeguards and mitigation measures. The use of blast

walls rather than, or in combination with, safety gaps needs to

be evaluated.

The use of wireless networks should also be promoted to

reduce layout footprint and topside weight.

A better understanding of operation and maintenance can

be used to define new approaches that can help reduce the size

of the living quarters.

Cooling

Indirect seawater cooling with a deep inlet riser to take

advantage of cold temperatures is a major advantage

compared to onshore LNG. It increases LNG capacity by

reducing the precooling refrigerant condensing temperature

and can optionally be used to cool the gas turbine inlet air

to increase the available power in warm weather and hence

production.

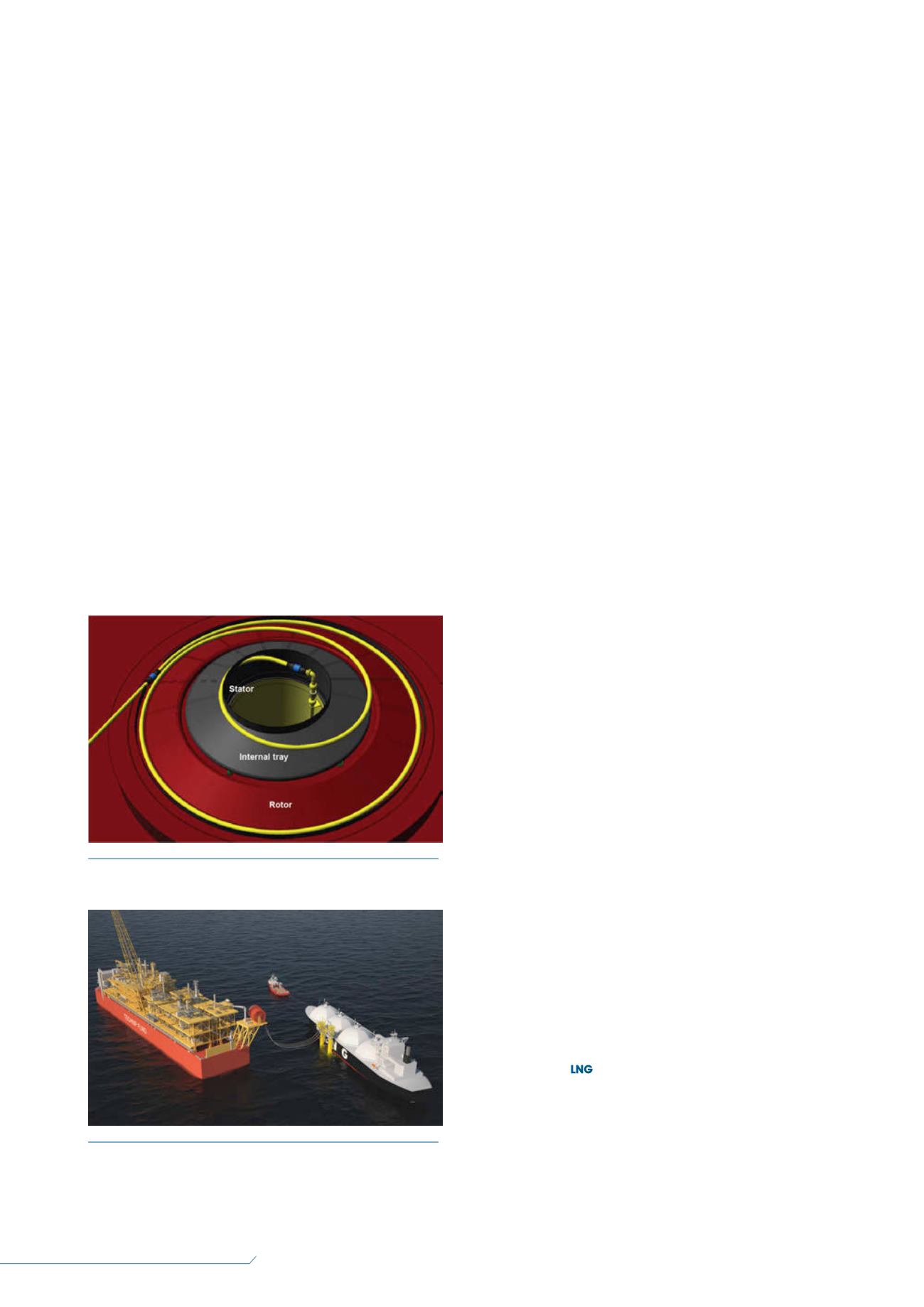

LNG handling

As LNG production is intensified, the ratio of storage to

production declines so that frequency of offloading to tankers

must increase. HiLoad LNG is one solution:

Connection and uninterrupted loading in sea states above

4 m wave height (H

s

).

Approximately 100 m separation distance at all times

between the LNG carrier and the FLNG facility.

Use of any LNG carrier without modification: connection to

the LNG carrier midship manifold without any load on the

flanges.

Control of LNG carrier heading and movement by HiLoad.

Proven components: Sevan HiLoad (references in oil

transfer) and Technip cryogenic flexible pipe.

Summary

Whatever solution is adopted, FLNG has an important

advantage over onshore LNG. It allows a more sustainable

development of offshore gas reserves by avoiding disruption to

sensitive and valuable coastal environments.

Replication will remain a key feature of FLNG, as it brings

schedule and cost certainty.

If the large capacity FLNG concept is developed, Technip

believes that its widespread replication and application will

follow. FLNG will thereby benefit from both routes – innovation

and replication.

References

1.

LNG17-proceedings/12-1-Barend_Pek.pdf

2.

/

scarborough_enviro_final.pdf

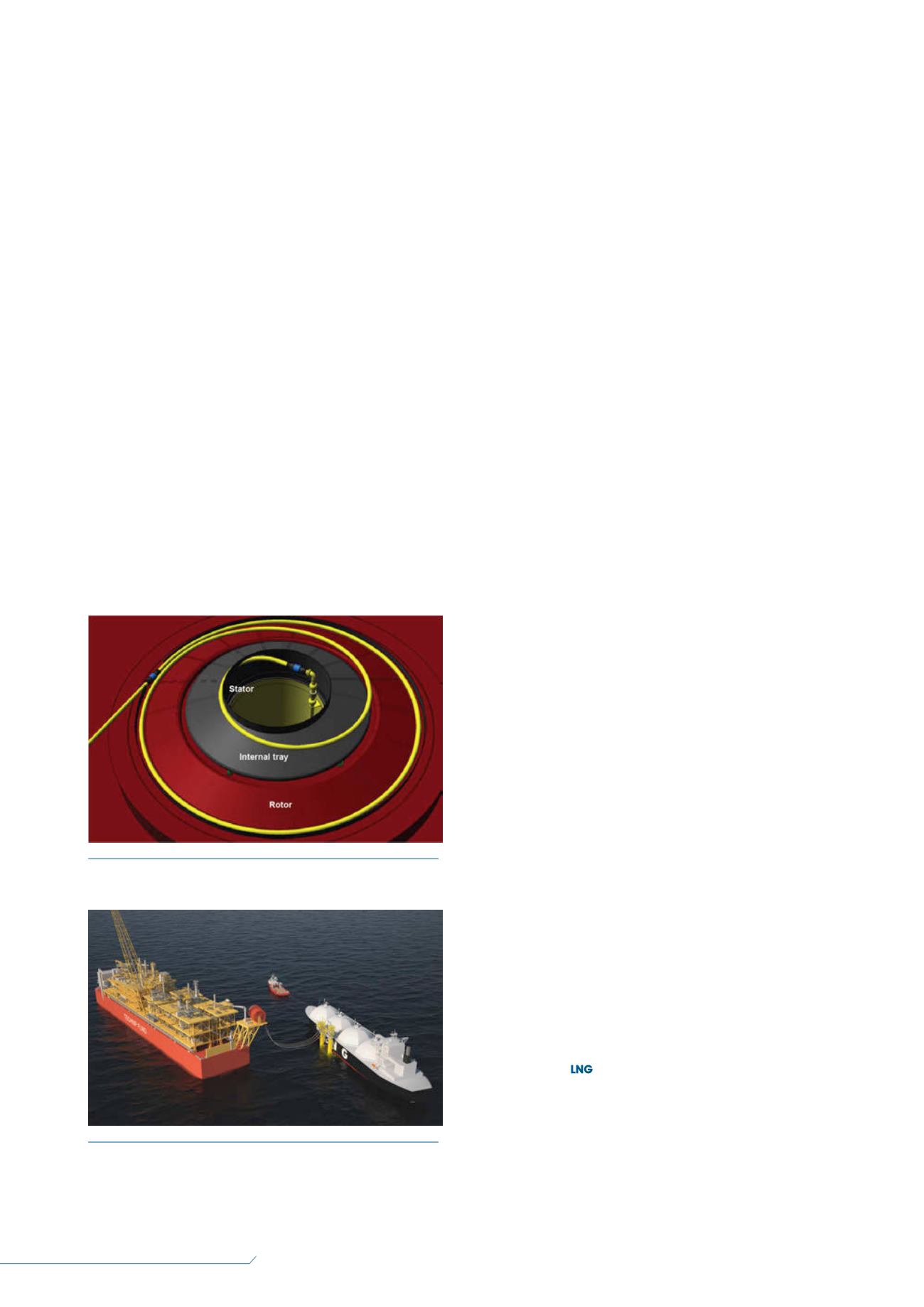

Figure 4.

Technip’s SST typical layout.

Figure 5.

The HiLoad LNG Parallel Loading System using

Technip’s ALLS cryogenic flexible flowlines.