22

LNG

INDUSTRY

MARCH

2016

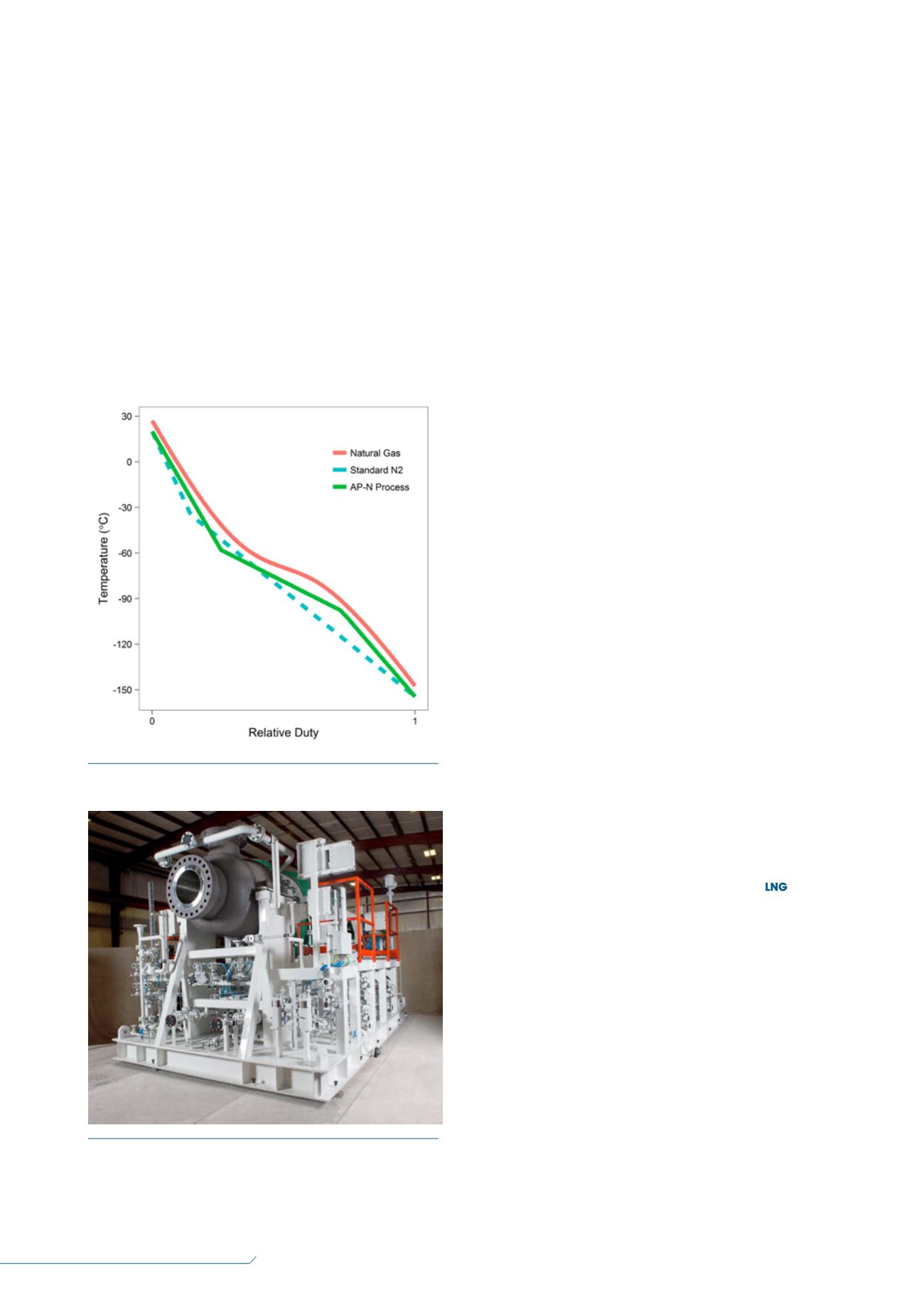

are all gas phase and the hot and returning cold flow are

inherently balanced.

Instead of simply scaling up the standard nitrogen

process by placing the three expanders in parallel, they

are arranged to optimise the cooling curves for both the

liquefaction exchanger and the economiser exchangers.

The cooling curve for the AP-N liquefaction cycle is given

in Figure 5. The arrangement of the expanders allows for

two bends in the refrigerant cooling curve, such that this

refrigerant curve follows more closely with the feed

cooling curve, creating a more efficient process.

One expander is used on warm nitrogen to provide

precooling refrigeration and another larger expander is

used on colder nitrogen to provide the refrigeration for

the liquefaction. The third remains on the coldest

nitrogen to provide refrigeration for subcooling.

Turboexpanders

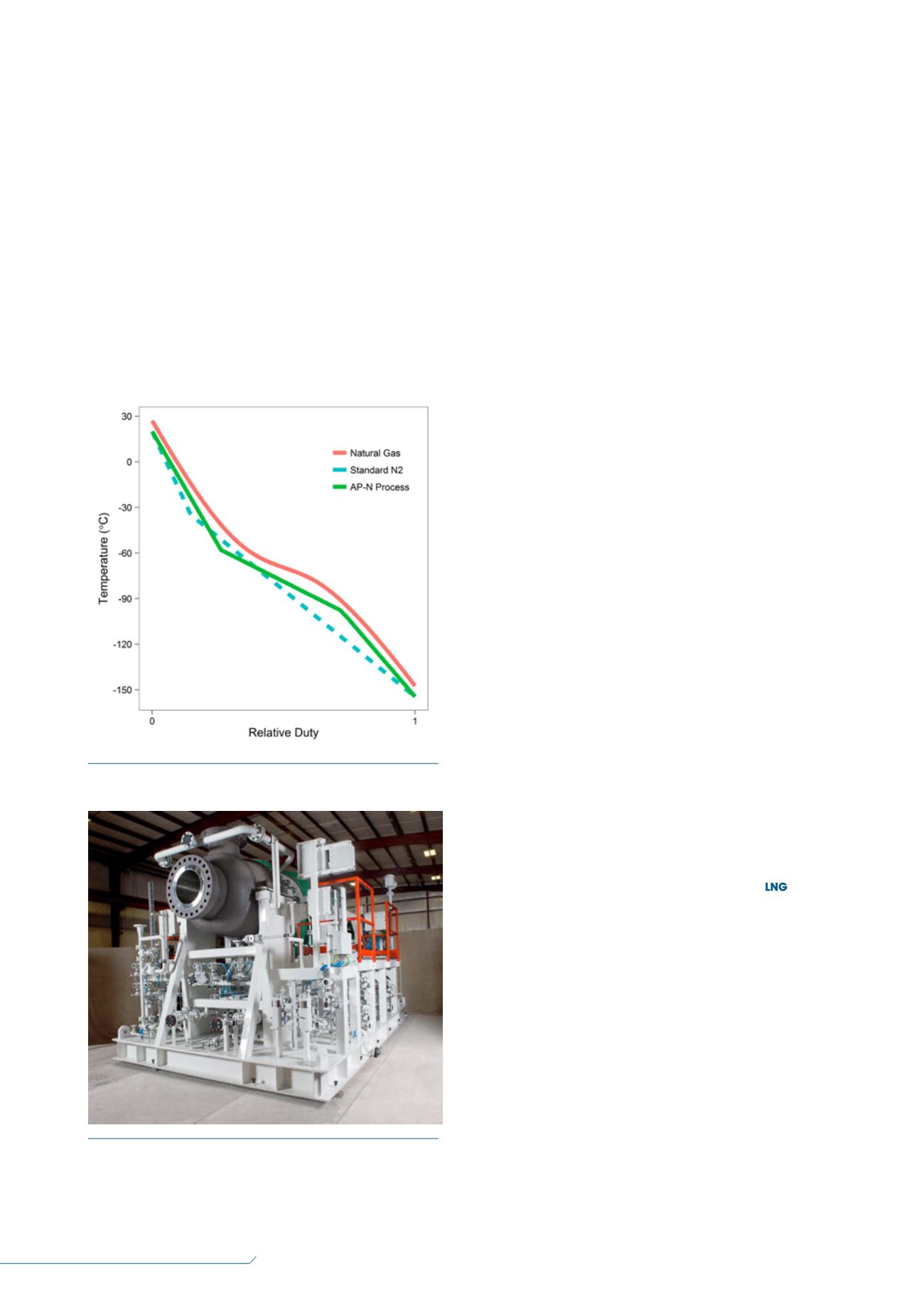

The expander arrangement in the AP-N liquefaction

process is such that each has a separate refrigeration

duty. Although not shown in Figure 5, the work generated

by the expanders is used to provide the final stage of

compression in a parallel compressor arrangement. This

arrangement requires that the expander-compressor

(compander, Figure 6) units work harmoniously together

while providing the individual adjustability to properly

balance and regulate the refrigeration for each service.

Therefore, the compander design team must work

closely with the process engineering team to ensure

that the companders will be able to provide the required

refrigeration and compression, as well as the operational

flexibility and durability required for all steady state and

transient operating conditions.

As with all shipboard equipment, there are challenges

and trade-offs with respect to weight, deck space,

maintainability, operability and reliability. The

Air Products compander design package utilises rugged

oil bearing technology and robust passive thrust

balancing systems to enhance reliability and limit

operational constraints for a compact, robust and

maintainable package.

Conclusion

There are additional challenges when designing an LNG

plant for floating applications. A number of liquefaction

processes are available (each with their own unique

features) to address these challenges. AP-SMR and

AP-DMR are efficient liquefaction processes that use

boiling hydrocarbon refrigerants. The AP-N liquefaction

process uses a non-flammable single-phase refrigerant

and the rotating machinery is highly integrated for

increased efficiency. One similar aspect of each of

these three processes is that the natural gas is liquefied

in a robust coil wound heat exchanger for safety and

reliability. All are suitable for floating plant service and

each has its own attributes, which project developers

may find attractive for their specific application.

References

1. BUKOWSKI, J. D., LIU, Y., PILLARELLA, M. R.,

BOCCELLA, S. J., and KENNINGTON, W. A.,

‘Natural gas liquefaction technology for floating

LNG facilities’, 16

th

International Conference and

Exhibition on Liquefied Natural Gas, Houston, Texas,

US, (2010).

2. BUKOWSKI, J. D., LIU, Y., PILLARELLA, M. R.,

BOCCELLA, S. J., and KENNINGTON, W. A., ‘Take to

the seas’,

LNG Industry

, (January/February 2014),

pp. 34 – 40.

3. BRONFENBRENNER, J. C., PILLARELLA, M. R.,

and SOLOMON, J., ‘Selecting a suitable process’,

LNG Industry

, (Summer 2009), pp. 17 – 25.

4. ROBERTS, M. J., et al., ‘Liquefaction method and

system’, U.S. Patent: 8464551, 2013.

Figure 5.

Cooling curves for AP-N liquefaction process.

Figure 6.

Turboexpander for FLNG service.