70

LNG

INDUSTRY

JULY

2016

boxes can be loaded on and under deck). In this article, only the

geometric counting method will be used.

For a given commercial trade, the vessel speed is a function

of the weekly sailing (time interval between two calls of the

vessels from a given commercial service) vs the number of

vessels on the trade. Depending on arbitration between market

needs and other parameters, such as OPEX (including bunker fuel

costs), the commercial vessel speed might be adapted from

approximately 10 knots to more than 20 knots. As a result, the

propulsion must be optimised for a wide range of speeds.

Reference ship

As references for this study, two designs of 19 000 TEU class

container vessels were retained: one running on HFO, and

another running on natural gas.

The following are the most relevant design parameters used

for this study:

Length overall (LOA): 400m.

Beam: 59 m.

Depth: 30.2 m.

Container capacity: approximately 19 000 TEU (11 tiers on

deck; 11 tiers in hold).

Single screw layout, shaft line driven by a two-stroke diesel

engine without gearbox.

Propulsive power: 65 MW.

Design speed: 22 knots at scantling draft.

The aim of this study is to compare the different layouts of

diesel, dual-fuel and COGAS propulsion. The COGAS concept

strictly sticks to reference designs. Only the propulsion driver and

power generation plant are changed.

General description

As mentioned previously, the following two axes drive this

concept: increase the cargo capacity and decrease the ship’s

OPEX.

To achieve these goals, Marine Assistance and GTT decided

to investigate further in the following directions:

Replace the large and heavy two-stroke piston engines

(direct mechanical drive) with slow speed, in-line electric

motors powered by a power plant consisting of several gas

and steam turbines.

Use an electric propulsion system to remove the funnel

casing and replace it with container tiers.

Use membrane type tanks to bunker LNG.

Adopt a new layout with electric production and LNG tanks at

midship and electric propulsion aft.

The most interesting principle about electrically propelled

ships is to dissociate power generation from power consumption.

This provides a lot of flexibility and additional freedom for the

ship designer on the general arrangement of the vessel.

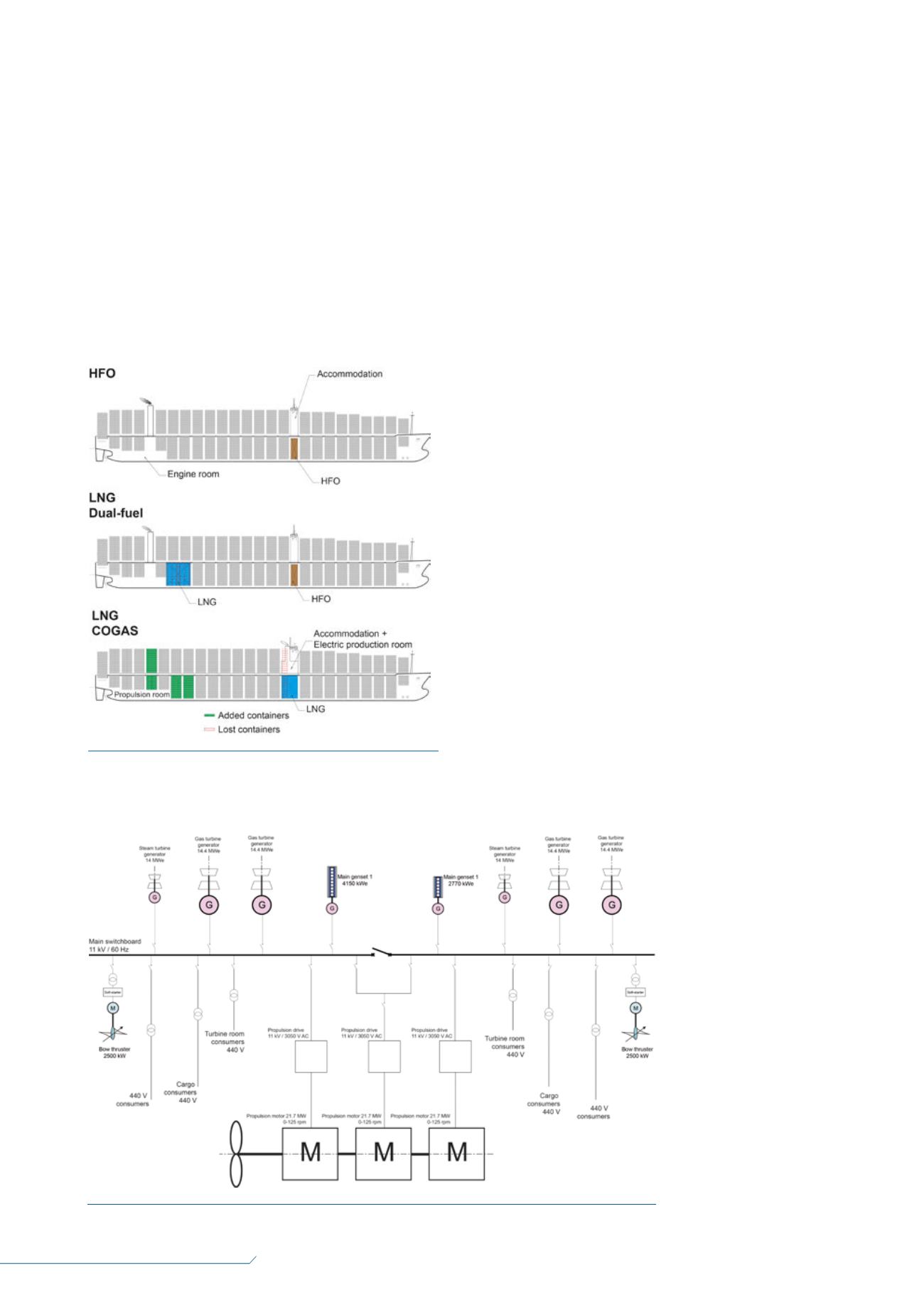

As can be seen in

Figure 1, the power

generation and the LNG

tanks are located below the

accommodation block in a

volume that cannot be used

for the cargo. At the aft of

the container carrier, a small

propulsion room replaces

the engine room, while the

funnel is suppressed,

enabling the vessel to carry

more containers.

LNG bunker

tanks

For a given volume of

bunker tanks, the amount of

energy contained in LNG is

only 60%of that contained

in HFO.

The consequence for an

LNG-fuelled vessel is

Figure 1.

Schematic layout of the combined gas electric

and steam (COGAS) concept vs diesel and dual-fuel reference

vessels (

©

Marine Assistance).

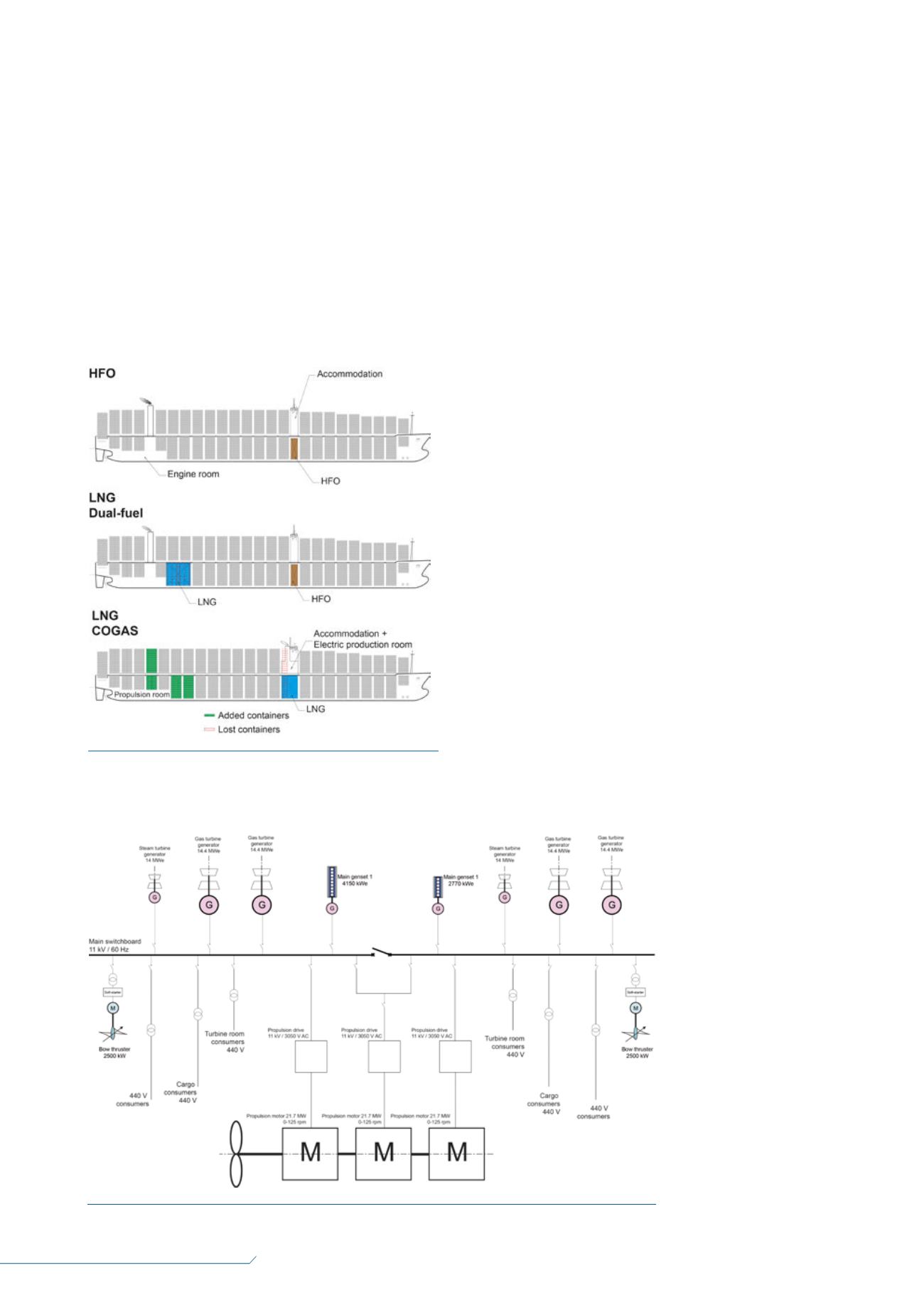

Figure 2.

COGAS preliminary electrical single line diagram (

©

Marine Assistance).