22

January 2020

drive train and to include auxiliary equipment that is not

always adding efficiency when the vessel runs in its

different operational modes.

Optimise according to conditions

Recently, drive trains with permanent magnet (PM)

machines and frequency converters have started to

gain momentum, because they have proved to offer

overwhelming technical advantages for distributed

power generation. The benefits are manifested in better

power production, wider speed operational range, better

electricity quality, as well as more stable voltage and

frequency.

Specifically with today’s small LNG tankers, the benefits

of these advanced drive trains based on PM technology are

bringing shipowners considerable added value.

One application that has caught the attention of the

industry, in particular, is the shaft generator. In this

application, the main engine is connected to a PM machine,

either via a gearbox or directly to the main shaft, to provide

electric power. The power created by the shaft generator is

then fed through a frequency converter, ensuring a stable

grid.

Some operators prefer to take the most from the use of

a shaft generator on board. They have realised that the

machine can be used additionally to boost power in icy

waters or harsh marine conditions or for peak shaving with

the use of batteries, prolonging the life of the main engine.

If this extra functionality is considered already during the

design phase, the main engine size can be smaller when a

shaft generator is used.

When flexibility is needed most

This application also allows a vessel to take full advantage

of various operational modes to achieve top performance

and efficiency on the job.

Operational modes offer a unique opportunity to

optimise and adjust how a ship is run according to the

existing conditions at hand. Moreover, they support the

main engine in special conditions when flexibility is

needed most.

For instance, a vessel can save energy when it has more

time available. Conversely, it can save travel time when

under pressure to reach its next destination.

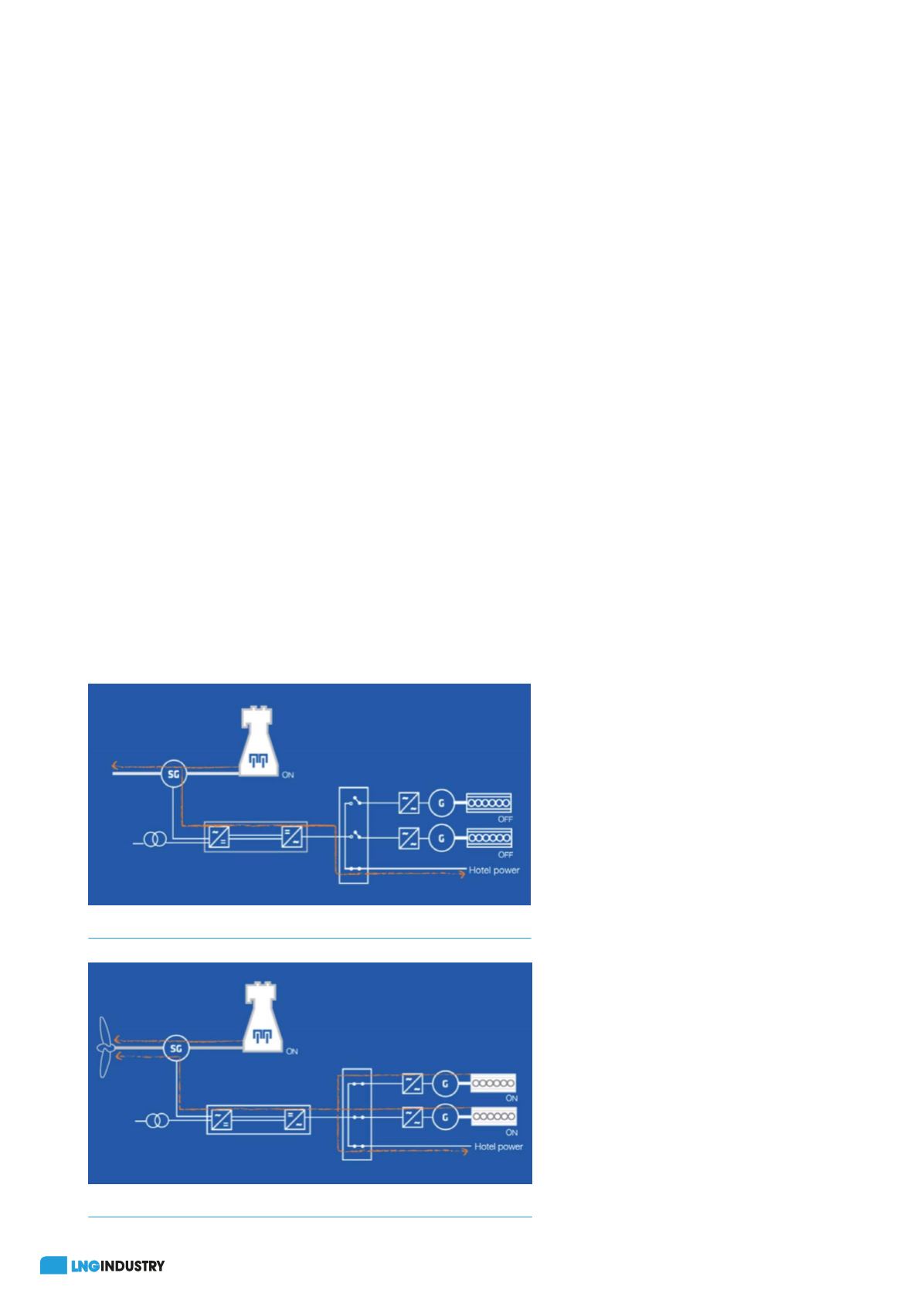

Power take out

The easiest and cheapest way to use extra power from

the main engine is to capture it with the power take out

(PTO) operational mode, which focuses on helping a vessel

improve its energy efficiency in power production. While

the main engine works as the power plant for the entire

ship, the PM machine works as a generator. The frequency

converter creates the electric grid by transforming the

variable frequency and voltage into constant frequency and

voltage. This constant, high-quality electricity can then be

used by all the consumers connected to the vessel’s grid.

The advantage of the PTO operational mode for LNG

tankers is that the auxiliary gensets can be shut off,

because the shaft generator and main engines produce the

power. This reduces the number of running hours for the

auxiliary generators, or can decrease their size, and cuts

back significantly on maintenance. Fuel efficiency, too,

improves considerably. Even better, the genset can be

completely replaced by a battery.

Especially for a small LNG tanker, this can

lead to more efficient performance at partial

loads, where the vessel spends most of its time

operating in any case, due to the nature of its

task.

Power take in

When extra propulsion power is needed, the

power take in (PTI) mode takes over as an

extra bonus. PTI offers additional flexibility,

increasing both safety and redundancy through

the use of the boost or take me home (TMH)

modes. Boost mode temporarily provides the

main engine with extra power, while TMH

mode kicks in during an emergency if the main

engine is not operational.

The main idea behind PTI mode is that it

can provide an additional or alternative source

of mechanical power for the propulsion. This

raises the level of redundancy in the propulsion

system and increases overall safety.

The PM machine works as a motor, and a

converter ensures the smooth operation of the

PM machine.

Boost mode comes into play when power

peaks are needed, for example, when a small

LNG tanker requires extra auxiliary power to

boost the main engine in demanding

operational conditions, such as sailing in icy

waters or against strong currents.

Figure 2.

Boost mode.

Figure 1.

Power take out mode.