20

January 2020

becomes an issue, which has to be reflected in the design

of the tank shell and tank supports, as well as the design

of the insulation and the connecting piping. Depending on

the tank diameter, the tank will see a shrinkage in height

of up 40 mm. With this shrinkage, the diameter of the tank

will also shrink between warm conditions and cold loading

conditions. The design of the supports, therefore, will have

to consider that the tanks will shrink ‘out of’ the support

during operation. For bilobe type tanks, this phenomenon

is intensified in the knuckle between the two tank halves.

For the early designs of the bilobe type LNG Type C tanks,

TGE Marine has applied a patented design, which moves

the interface between the hull and the tank from the

circumference of the tank into the horizontal plane of the

support. The application of this patent will ensure longevity

of the support, wooden blocks and insulation over the

lifetime of the vessel.

Type C tanks in the FSRU market

The development of Type C tanks has not stopped with

their application to the small scale fleet. Two other areas

of application are the small scale LNG floating storage and

regasification unit (FSRU) market, as well as the LNG fuel

gas market. In the FSRU market, regasification barges can

be equipped with Type C tanks as storage, either sized for

small scale LNG parcels, or to increase the storage volume

in combination with a floating storage unit (FSU). Usually,

older LNG carriers are used as FSUs, but because they are

smaller in volume than modern LNG carriers, they would

not be able to complete parcels out of the supply chain as

a standalone solution. This can be achieved in combination

with added storage on the regasification barge. For this

application, the largest ever cylindrical LNG Type C tank

was recently fabricated by TGE Marine. The volume of this

tank is 14 000 m³, with a length of 74 m and a diameter

of 16 m. Type C tanks have generally increased in volume,

and the boundaries been pushed further by the newly

established ethane trade out of the US to Europe or Asia

calling for a new segment of large or very large ethane

carriers (VLECs). For large ethane carriers with a storage

capacity of 35 000 – 37 000 m³, the largest bilobe Type C

tanks with 12 000 m³ of single tank capacity have been

delivered. One particular design of the delivered VLECs

with a total capacity 84 000 m³ is equipped with trilobe

type tank design.

Application for LNG fuel

As stated above, size is not an issue for Type C tanks.

However, in the smaller range, volume efficiency and

therefore shape become the main challange. This smaller

range of Type C tanks with volumes of 300

–

3000 m³ has

found a new market in the application as LNG fuel tanks.

Here the tanks are used to store LNG as fuel on merchant

vessels of any kind. These can be cruise vessels, container

vessels, bulk carriers, car carriers, or any other type of vessel.

For this reason, Type C tanks have been integrated in the

IGF Code as one possible solution for fuel gas storage.

From a size of 300 m³, conventional insulated Type C tanks

are the most economical solution compared to vacuum

insulated tanks. Vacuum insulated tanks are further limited

in size and shape. While for a ship type with sufficient deck

space, conventional cylindrical tanks are used, this becomes

difficult for container vessels (for example), where lost space

is equivalent to loss in cargo capacity.

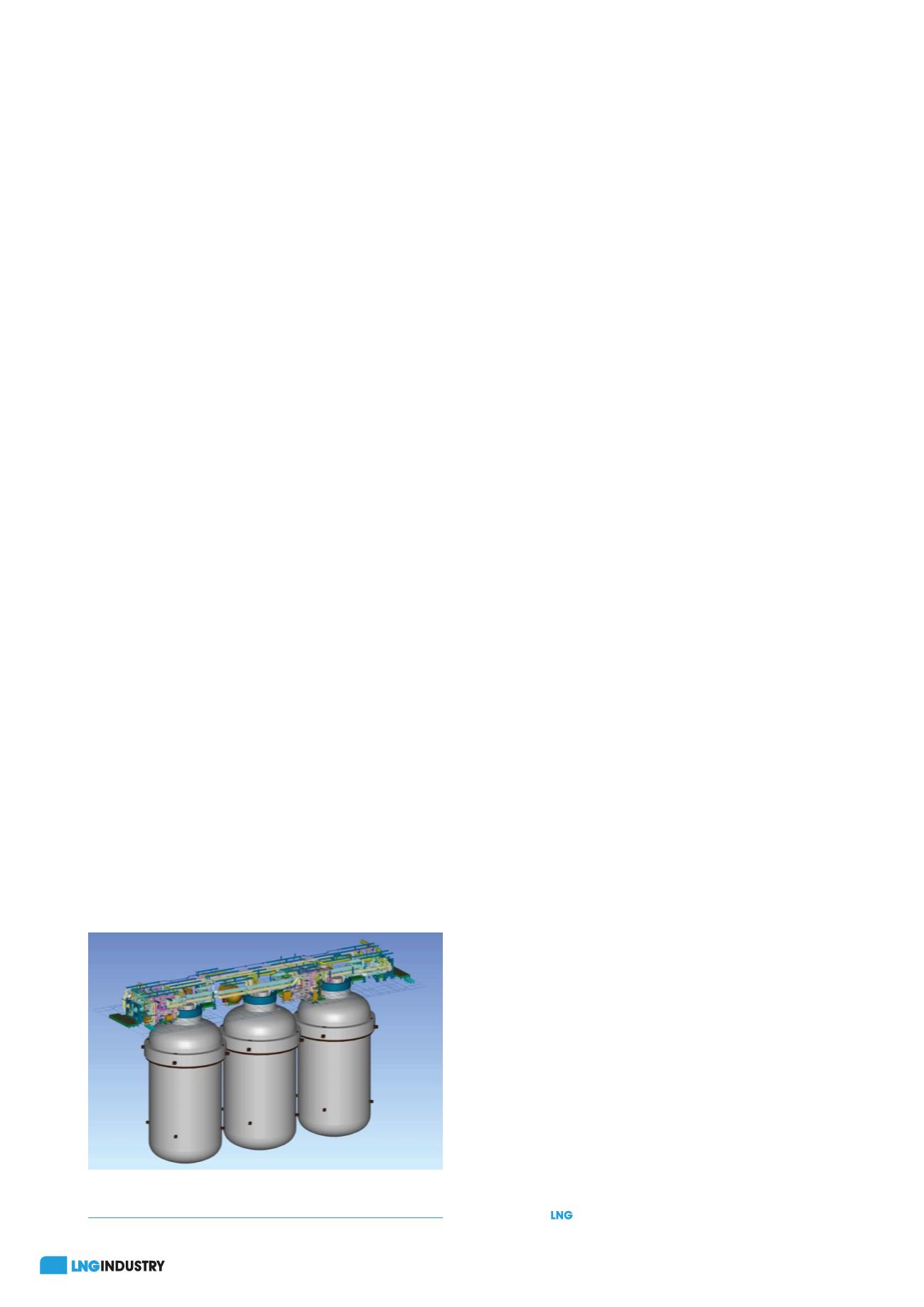

Trilobe shapes and vertical

arrangment

For the conversion of the 1000 TEU container vessel

Wes Amelie

, a solution could be found with the installation

of the cylindrical fuel tanks in the forecastle, minimising

the loss in cargo space. For a 1400 TEU vessel, however,

TGE Marine took a more innovative approach. The three fuel

tanks on this vessel were installed in a vertical arrangement

suspended into a fold space, essentially representing one

container bay in the hull, and supported by a ring type

support. The upper ring type support is used to keep the

stresses on the topside piping connections to a minimum.

The tanks experience the main part of the shrinkage below

the ring type support. The same concept has been used

for the eight vertical Type C tanks used as fuel tanks on

Heerema’s crane platform,

Sleipnir

. The volume of each

fuel tank amounts to 1100 m³, providing a total capacity of

approximately 8000 m³ of LNG as fuel.

Taking the shape of LNG Type C fuel tank one step further,

TGE Marine has recently developed a trilobe Type C tank. The

three cylindrical parts of the tank are arranged horizontally in

transverse direction to the ship’s longitudinal axis. The tank

has been developed with the restrictions of larger container

vessels in mind. Losing only one container bay, a total volume

of 6000 – 8000 m³ can be achieved. A benchmark in

volumetric efficiency has shown that these tanks can achieve

a similar volumetric capacity to membrane type tanks, while

keeping all the benefits of a Type C tank design.

Re-invention of the Type C tank

The development and extension of Type C tanks is not

surprising given the advantages of the Type C tank design

in terms of inherent safety, operational safety and ease of

project execution. Type C tanks are not an ‘old dog’, but can

rather be described as an established technology supporting

newly developed markets, such as the LNG fuel market, with

a long reference list and reducing the risks associated with

the application of new technologies. With new developments

and the adaption of existing technologies to new markets,

the ‘trick’ is to find the right solutions. The developments

in terms of size, shape and arrangement of Type C tanks

can fairly be called a re-invention of this long established

technology.

Figure 4.

Vertical fuel tank arrangement for a 1000 TEU

container vessel.