28

LNG

INDUSTRY

SEPTEMBER

2016

entropy production by using several refrigeration cycles

for each liquefaction stage. By evaporating the liquid

refrigerants, high thermodynamic efficiency can be

achieved. However, the process is complicated and

requires a large number of components, meaning that the

size requirement is large and the capital cost is high. The

high efficiency and high investment cost makes it suitable

for large land-based liquefaction plants.

Mixed refrigerant

MR liquefaction is also based on the Rankine cycle.

However, contrary to cascade cycles, a blend of

refrigerants is used to obtain a close following of the

natural gas cooling curve. By mixing refrigerants, a

temperature glide can be attained, which means that the

temperature at phase change will not be constant. This

is because the components in the mixture evaporate at

different temperatures, causing a change of concentration,

which can be adapted to the process gas cooling curve.

In reality, the MR will cause a curved temperature profile,

which will lower the thermodynamic efficiency, compared

to the cascade cycle. The MR process is suitable for

small scale liquefaction plants where the low equipment

count and simplicity can be a substitute for high efficiency.

Expander cycle

The expander cycle differs from the other liquefaction

cycles by using an expander instead of a Joule Thomson

(JT) valve. The expander is connected to the compressor,

and extracts useful power from the compressed gas.

The refrigerant used is a pure gas, and is only in gaseous

phase, making it insensitive to motion. This also

eliminates issues relating to the distribution of liquid

refrigerants in the heat exchangers, thereby allowing

rapid start-up. A gaseous phase refrigerant, however,

has a limited enthalpy difference, and requires a higher

refrigerant flow than two-phase refrigerants, which limits

the capacity. The process does not follow the cooling

curve of the process gas very well, which results in lower

efficiency than with other technologies. This, on the other

hand, makes the process more forgiving to variations in

the gas composition.

Most expander processes utilise the reversed Brayton

cycle (either closed or open loop) to generate cooling. This

is done either in a single or dual stage or with precooling.

By using an open-loop expander cycle, a fraction of the

process gas is utilised as a refrigerant. This eliminates the

need for excess refrigerants.

The reversed Stirling cycle is another type of expander

process used for liquefaction. The Stirling cycle is a

modified Carnot cycle, where heat from the compression

stage is utilised in the expansion stage, making it a

regenerative cycle.

Offshore reliquefaction

The selection of liquefaction technology for offshore

applications differs from the onshore equivalents. Space

on marine vessels is limited, which increases the need for a

compact solution.

The use of hazardous hydrocarbons has to be limited

for safety reasons.

Small scale offshore reliquefaction is, from a capacity

perspective, quite similar to onshore peak shaving plants.

The expander cycle is a proven technology for these

small scale plants and is a viable choice for offshore

reliquefaction.

Thermal oxidation

Another method for handling BOG is thermal oxidation

(i.e. combustion). This is primarily done by feeding the

excess gas to the consumers (i.e. the ship’s engines). Two

and four-stroke internal combustion engines are normally

used for propulsion and power generation, while two-stroke

engines usually have a high power output and are used for

direct propulsion. Four-stroke engines can be used both as

main and auxiliary engines, the latter being used while in

port, as well as when at sea. Additionally, auxiliary boilers

can be used to produce steam or hot water. If the amount

of BOG does not correspond to the rate of consumption,

the gas can be fed to a gas combustion unit (GCU). The

GCU is a burner which combusts the BOG in a controlled

manner without the risk of releasing unburned natural gas

to the atmosphere. Although a possible solution for BOG

handling, no useful energy can be recovered from a GCU,

which is why it should primarily be recovered by other

means.

Compression

Feeding gas to the engines is one way of handling BOG in

the tanks. Four-stroke engines usually have a suitable fuel

pressure need for Type C tanks and can consume the gas

at tank pressure. Two-stroke engines, however, demand

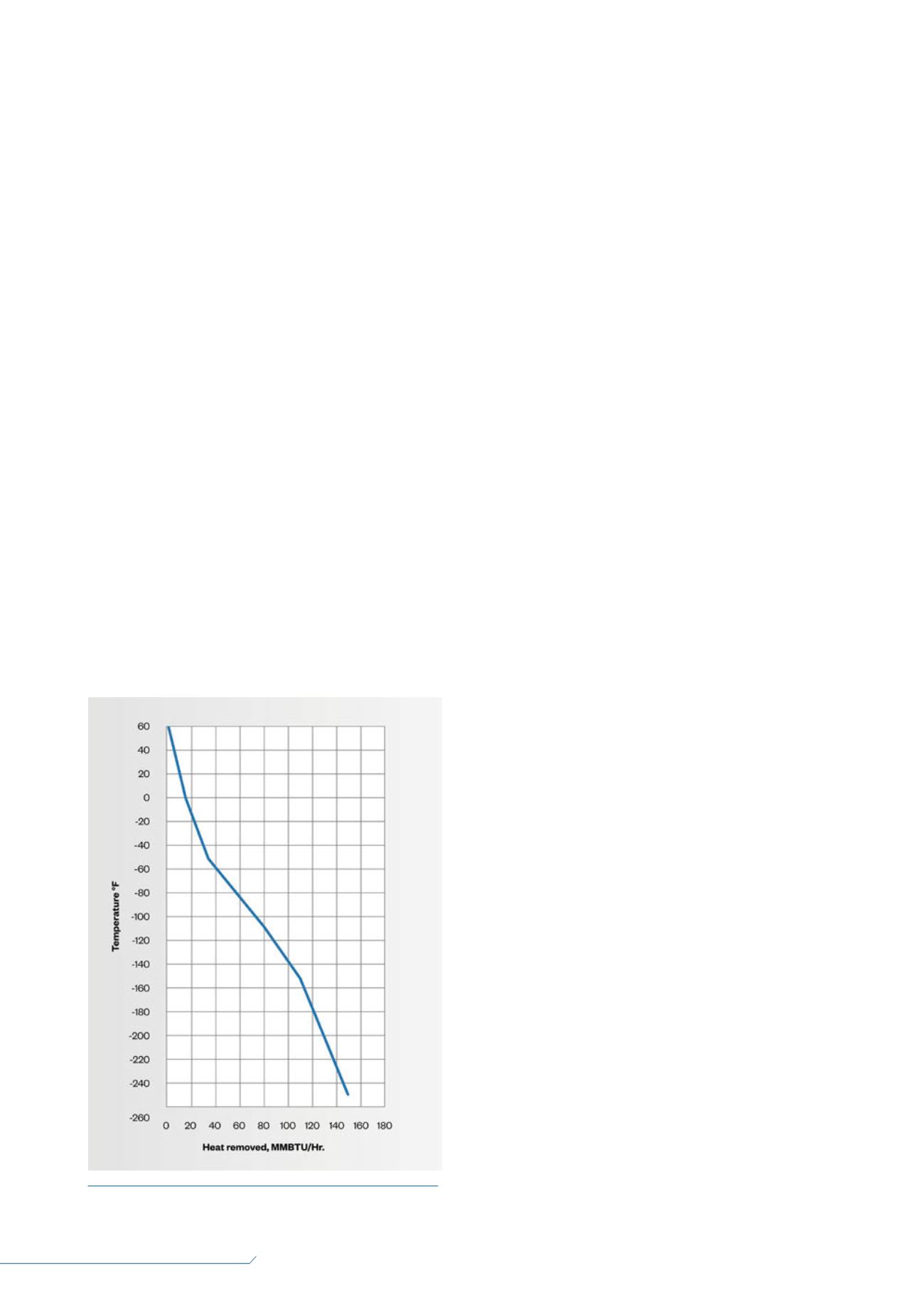

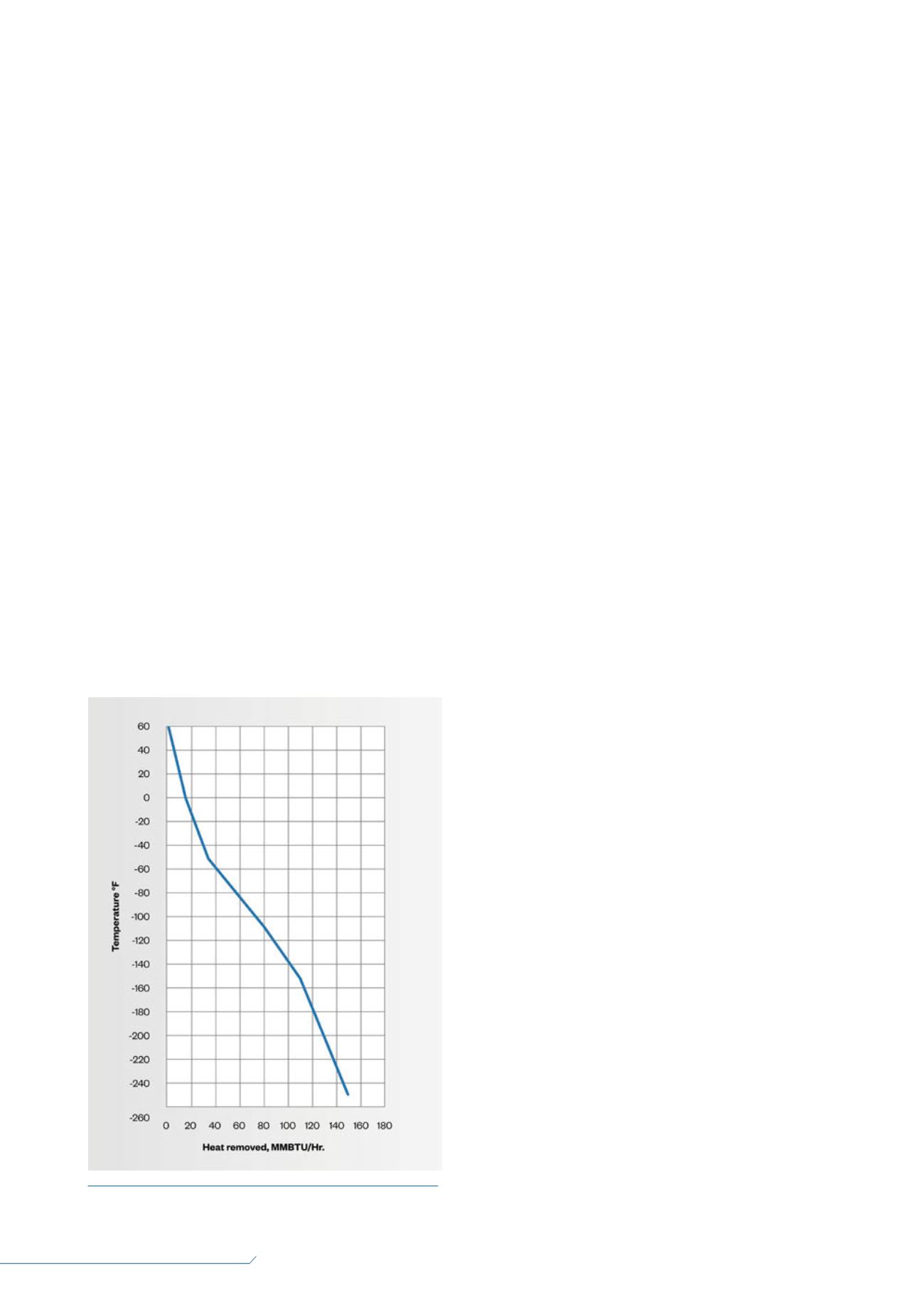

Figure 3.

The three-stage cooling curve of natural gas

(15 – -161°C) with precooling, liquefaction and subcooling.