20

LNG

INDUSTRY

SEPTEMBER

2016

on reduced timing, in order to put the vessel back into

operation within the shortest possible window. A

skid-mounted solution was chosen to comply with such

requirements, improving the delivery time and the

installation time.

The design steps were as follows:

Interface and basic data verification to fix the design

basis.

Basic design producing piping and instrumentation

diagrams (PIDs).

Basic design review with all parties (owner/shipyard/

class).

Part of the basic design review: implementation

of hazard identification study (HAZID)/hazard and

operability study (HAZOP) recommendations.

Detail design, including signal exchange and

automation.

3D review arrangement with a focus on safety and

maintenance access, including implementation of

recommendations from class and operators.

Failure mode and effects analysis (FMEA) with ABS

consulting.

Implementation of FMEA recommendations and

reviews.

High pressure system simulation used from the

beginning to verify functionality and automation of

the high pressure system, with a final ‘software in the

loop’ simulation test.

There was a particular focus on the integration of the

systems with the existing automation of the vessel. In this

regard, TGE’s engineering team closely cooperated with

the University of Cologne on the development of a control

system, which can cope with high speed load profiles

imposed by two-stroke dual-fuel main engines while

running on LNG as a primary fuel. Meanwhile, a European

patent has been granted for this control system with

patent application pending in many other countries. The

control system has been comprehensively tested on board

and is working perfectly under different profiles with two

main engines in operation.

Who is next?

Following the example of Nakilat, many other projects,

mainly with high pressure MAN ME-GI engines, followed,

for which TGE designed and delivered the fuel gas

systems and LNG tanks.

Navigator Gas ordered a series of ethylene tankers

with LNG fuel propulsion. The LNG will be stored in a

dedicated deck tank with polystyrene insulation slabs

(foam-insulated) and the fuel gas system will provide the

natural gas to both high pressure main engines and low

pressure auxiliary engines. The gas trial was held at the

end of June 2016.

Crowley Maritime Corp. ordered two ConRo ships,

which are some of the first LNG-powered, combination

container and RoRo (ConRo) vessels in the world. The

vessels will be in service between the US and Puerto Rico.

Rasheeda

Qatari shipping company Nakilat decided to convert

the high pressure main engine of its 266 000 m

3

Q-Max

vessel,

Rasheeda

. This led to a reduction in sulfur, SO

X

and

NO

X

emissions, as well as reduced fuel consumption.

In October 2015, Qatargas, together with engine

manufacturer MAN Diesel & Turbo and TGE Marine Gas

Engineering (who supplied the LNG fuel gas system),

announced that the commissioning of the Q-Max vessel

was successfully completed, setting new milestones and

benchmarks for LNG as marine fuel.

The vessel propulsion is provided by two MAN

two-stroke engines MAN B&W 7S70 ME-C, with a total

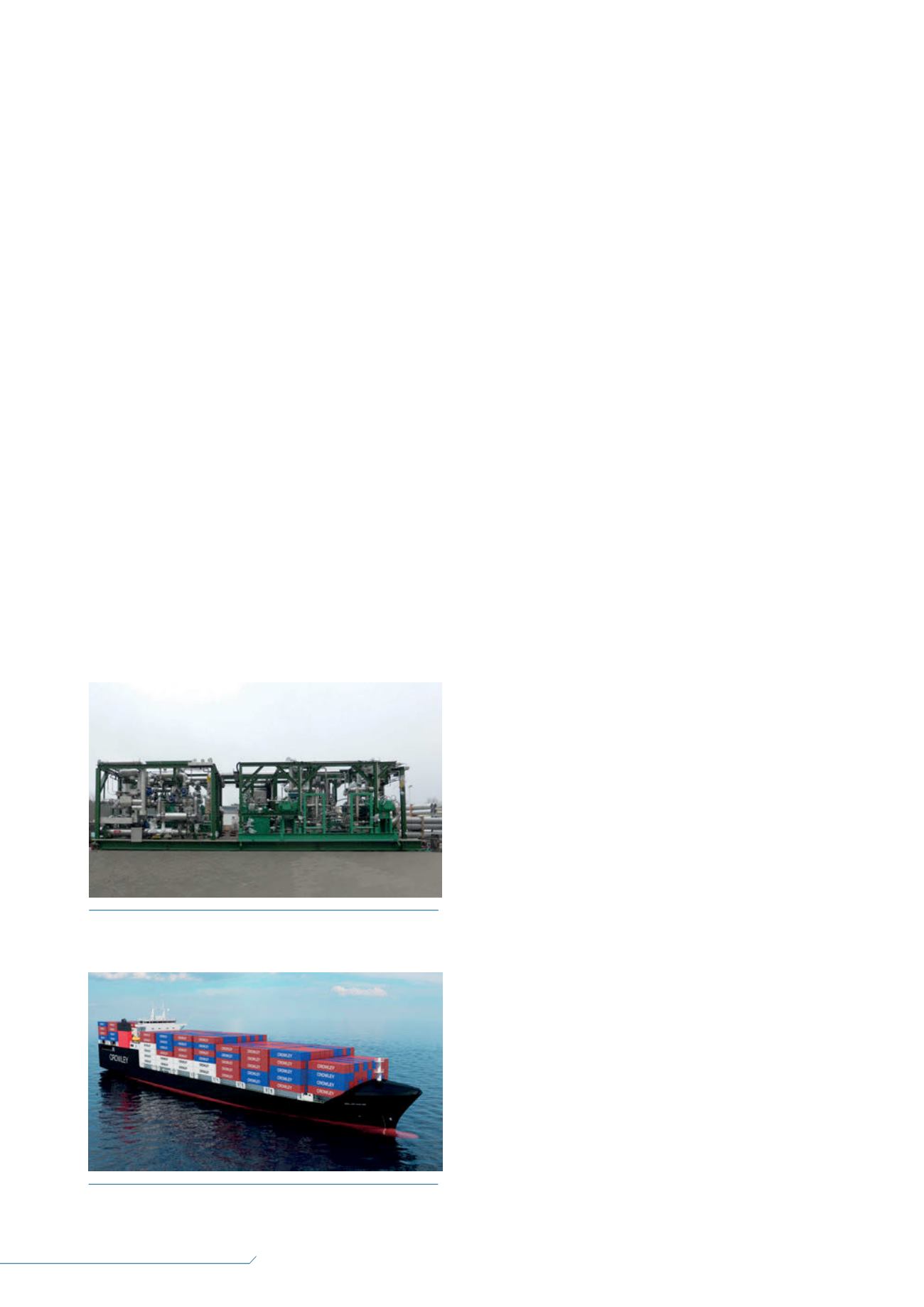

power of approximately 38 000 kW. The skid-mounted

fuel gas system, provided by TGE, consists of the

following:

Low pressure LNG pumps.

A buffer LNG tank.

High pressure LNG pumps.

A high pressure vaporising unit.

An integrated automation system extension.

The LNG will be taken directly from the main tanks

through the low pressure booster pump and sent to the

high pressure pump through a small deck tank. The LNG

fuel gas system has to provide the fuel gas at 300+ barg

to the engines.

The biggest challenge for MAN and TGE, according to

Nakilat requirements, was to complete the retrofit based

Figure 2.

TGE Marine Gas Engineering’s high pressure skid on

Rasheeda

.

Figure 3.

Crowley Maritime’s ConRo ship.