26

LNG

INDUSTRY

SEPTEMBER

2016

The larger volume of gaseous natural gas created by

this BOG will increase the tank pressure. To manage this,

pressure vessels are utilised to contain the pressure. For

longer storage periods, however, the pressure increases

might be too high, which will require alternative solutions

to handle the gas pressure.

Wärtsilä has extensively studied the handling of BOG

on board LNG-fuelled ships. This article is based on these

studies.

Pressure build-up

Pressure build-up depends on several parameters, including

ambient temperature and the amount of LNG in the tank.

Another aspect to consider is stratification, which may cause

a faster pressure rise. Stratification means that the LNG

is divided into layers with the higher density liquid at the

bottom and the lower density liquid on top. When the lower

layer is heated, it cannot evaporate because of the cover.

The densities of the layers are eventually equalised due to

boil-off from the top layer and heat transfer. The warmer

LNG from the bottom rises to the top and evaporates. This

is called rollover and causes a rapid increase in the boil-off

rate (BOR), which is difficult to predict.

Thermal stratification can be eliminated by agitating

the tank, which occurs naturally on gas-fuelled ships due to

the motion of the waves. Agitation of the tank may cause

an opposite reaction when warm LNG is mixed with colder

LNG, since the temperature at the surface will then

decrease and condensate the BOG. The result is a collapse

of pressure, which is followed by saturation at a lower

pressure.

BOG handling requirements

There are various means of handling the pressure build-up

in LNG tanks. One method is to contain the pressure for

the ambient temperature of the fuel. Other methods

include reliquefaction, thermal oxidation, and pressure

accumulation. The IGF code – the international safety

code for ships using gases or other low flashpoint fuels

– also accepts cooling of the fuel in a liquid state. For

reliquefaction, a direct system, where the evaporated gas

is compressed and condensed before being returned to

the tank, is one solution. The other alternative is an indirect

system, where the gas is condensed or cooled with an

external refrigerant, without being compressed.

Apart from handling the maximal BOR in the tank, the

selected method also needs to cope with zero or low BORs.

In the case of failure, the system must provide a redundant

system that can maintain the tank pressure. Venting gas to

the atmosphere is not an alternative for pressure control,

and is only allowed in emergency

situations.

Reliquefaction

Several licensed refrigeration

processes are available for the

liquefaction of natural gas. These

processes use one or more cycles

in order to imitate the cooling

curve of natural gas. A good match

of the curve will give the process

high efficiency and, therefore, low

energy consumption. Conversely,

a low temperature difference

between the refrigerant and the gas

will demand a larger heat exchange

area. Refrigeration process design

is about optimising the number of

cycles, the refrigerant composition,

and the heat exchange area.

The result depends on whether

simplicity, efficiency, a compact

footprint, or low cost is the key

boundary condition. Depending

on which refrigeration cycle is

used, liquefaction processes can

be divided into three categories:

cascade cycle, mixed refrigerant

(MR), and expander cycle.

Cascade cycle

The cascade process is defined

by several cascaded refrigeration

cycles, based on the reversed

Rankine cycle, using pure two-phase

refrigerants. The idea is to reduce

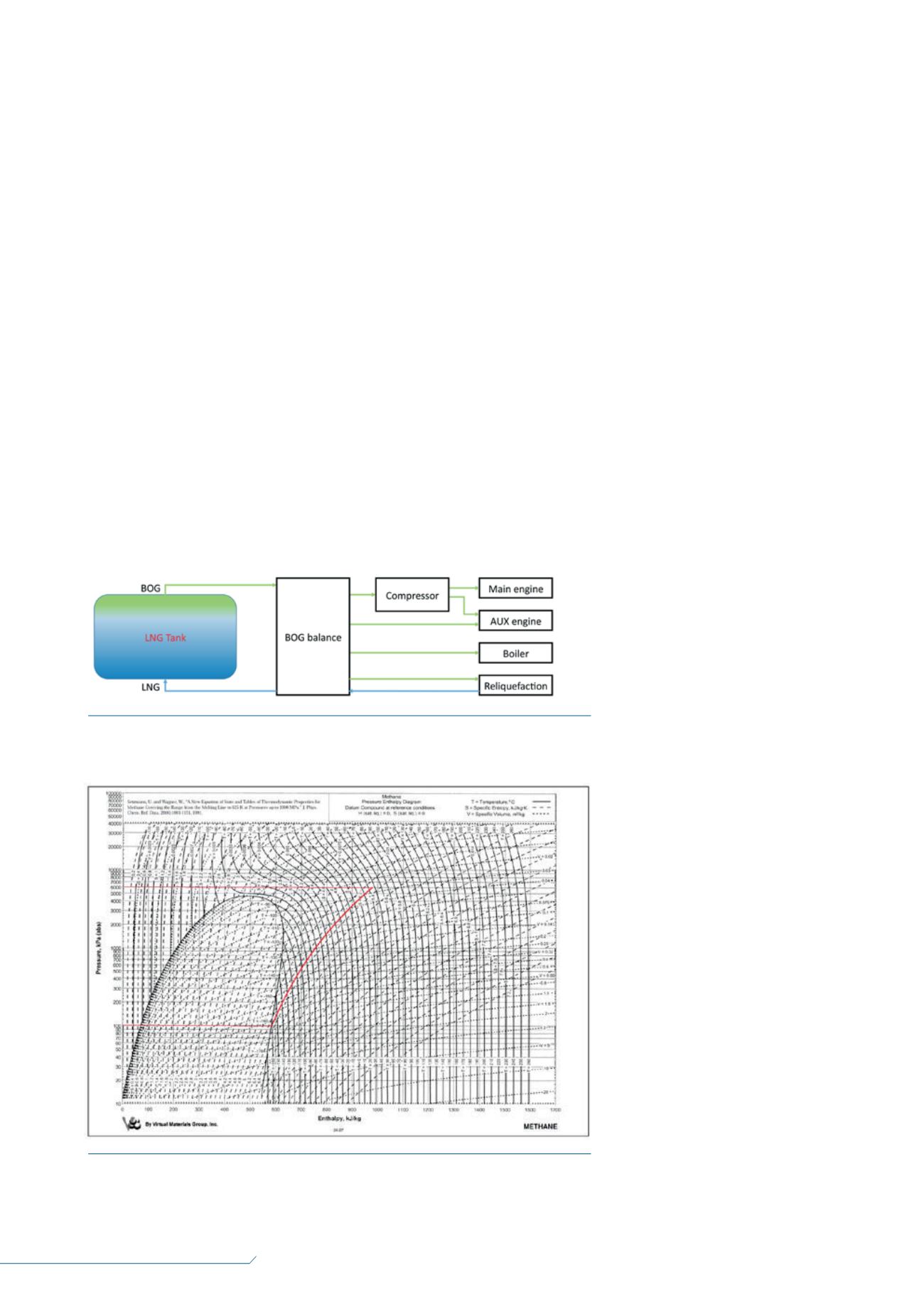

Figure 2.

Illustration of an isochoric temperature increase of methane from -162°C at

atmospheric pressure to 45°C (upper design temperature for worldwide service). The result is

a pressure of approximately 60 bar.

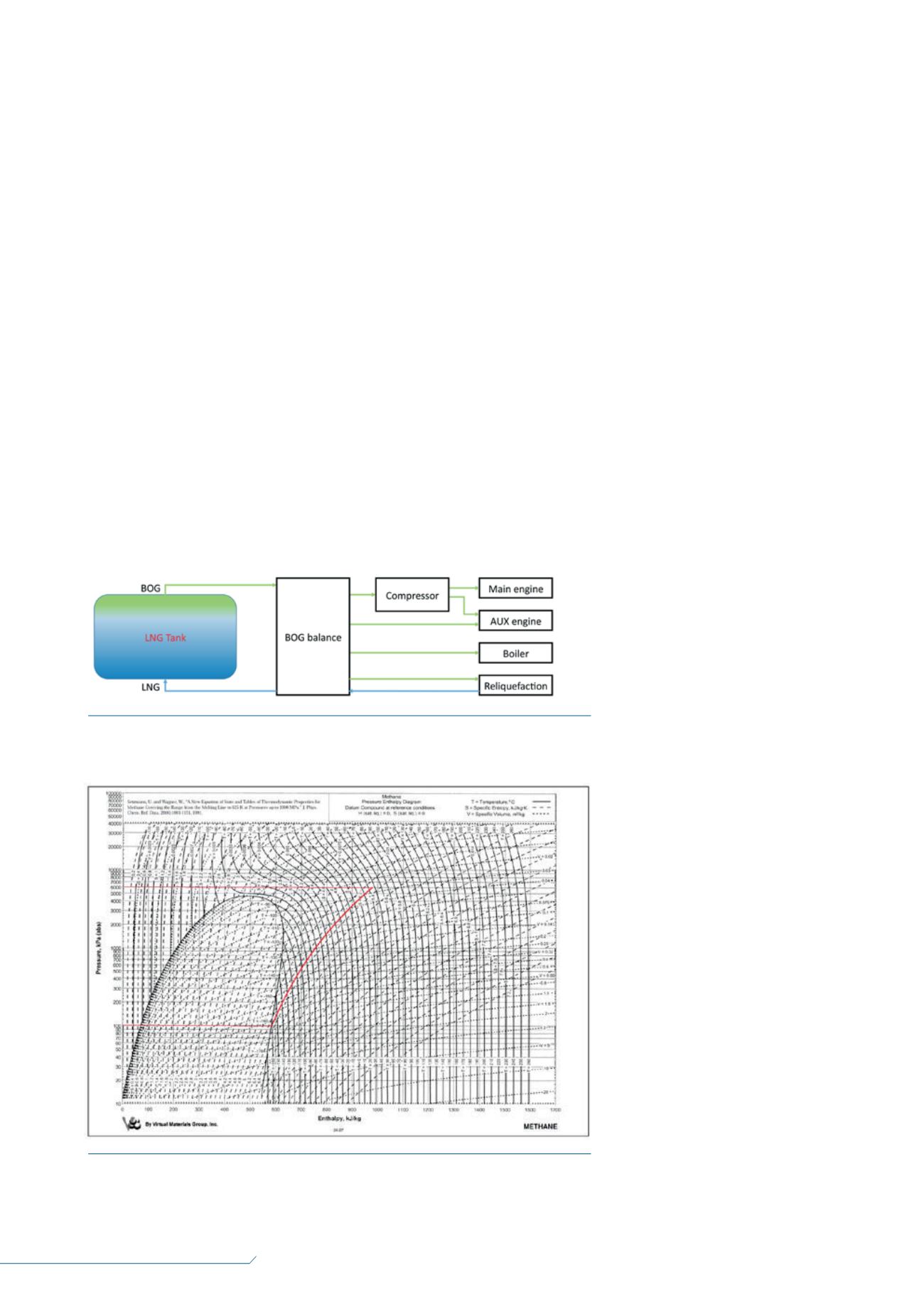

Figure 1.

Simplified system layout for boil-off gas (BOG) handling, when using two-stroke

main engines and four-stroke auxiliary engines. Ideally, consumption should match boil-off

rate (BOR), resulting in a BOG balance of zero.