SEPTEMBER

2016

LNG

INDUSTRY

35

engineering, procurement and construction (TEPC) teams. With

the facility requirements, the TEPC teams will next develop

competing conceptual (FEP-1) and preliminary (FEP-2) designs

and cost/schedule estimates. The developer will then evaluate

these proposals to see which solution best fits the project needs.

The successful bidder is then awarded a firm price contract for

detail design, procurement and construction in FEP-3. Typically,

technology providers team up with engineering, procurement

and construction (EPC) contractors to provide proposals. The

TEPC teammodels followmultiple structures, such as a joint

venture (JV) or a consortium. Certain TEPC organisations can

come from one single entity as well.

An alternate approach is for the developer to solicit

competing unfunded FEP-1 work from TEPC teams. At the end of

FEP-1, two TEPC teams are funded to develop FEP-2 packages

and compete to be chosen for FEP-3 and beyond activities. With

the estimates and preliminary documents developed in FEP-2 by

each team, the developer will confirm the project economics and

make a final selection of the TEPC team to proceed with detail

design (FEP-3). Finally, the selected TEPC team executes the

procurement and construction of the facility using a target price

with incentive model contracting method.

This alternate approach typically requires less overall time

and minimises time to market. The cost optimisation risk of

selecting a TEPC earlier is offset by the schedule optimisation

and faster time to market.

This alternate approach will result in the following:

A clearer understanding of the project objectives by the

developer and the TEPC.

The development of mutually beneficial contracting terms.

Value engineering to effectively lower costs.

To initiate FEP-1 and FEP-2, the basic performance

requirements for the facility need to be defined by the developer.

These include:

Feed gas composition and variability.

Required LNG output

(flowrates, pressures).

LNG delivery method

(truck fill, cryogenic

pipeline to berth for

ship or bunkering

barge).

Facility location and

footprint constraints.

FEP-1:

concept

During this sub phase,

proposals are solicited from

the technology providers.

Based on submissions,

facility information is

further developed and

refined. Capital costs,

schedule and operating

costs are parametrically

estimated, and competing

ROI models for each

technology are prepared.

Items completed may include options to reserve identified

potential plant property while additional evaluations are made,

and additional geotechnical data to firm up foundation design

recommendations.

At the end of FEP-1, the developer selects the technology

that best furthers his/her business interests and identifies at least

two technology vendors, and, secondly, has a rough order of

magnitude estimate of costs (+50%/-30%).

FEP-2: detailed scope

During this phase, suppliers are invited to provide technical and

commercial proposals based on any changes and/or revisions

resulting from the balance of plant. Upon receipt and evaluation

of the proposals, the facility design and process can be finalised

so that it can be handed off for detailed engineering. FEP-2

outcomes include a +/-30% EPC cost estimate, an operating

cost estimate and a preliminary project schedule.

FEP-3: design

Once the FEP-2 or front end engineering design (FEED) teams

are selected and contracts placed, the teams will begin

preliminary designs. Key decisions by each team include the

following:

Liquefaction processes.

On-site buffer LNG storage to meet the required throughput.

Sizing of major equipment, such as gas pretreatment,

compressors, heat exchangers and pumps.

Initial facility layout.

Utility demands.

The main deliverables include the following preliminary

documents:

Process flow diagram (PFD).

Piping and instrumentation diagrams (P&ID).

Plot plan.

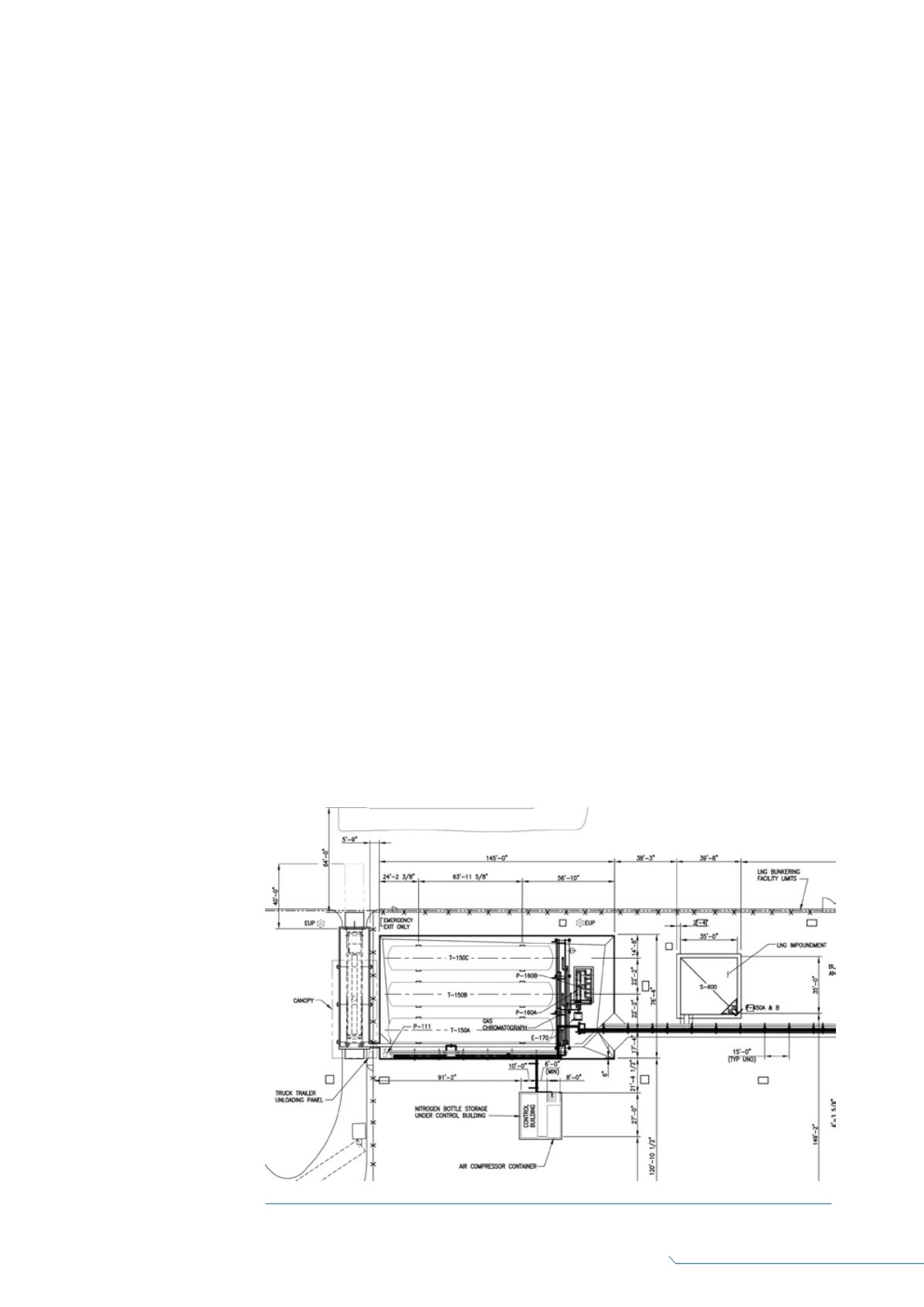

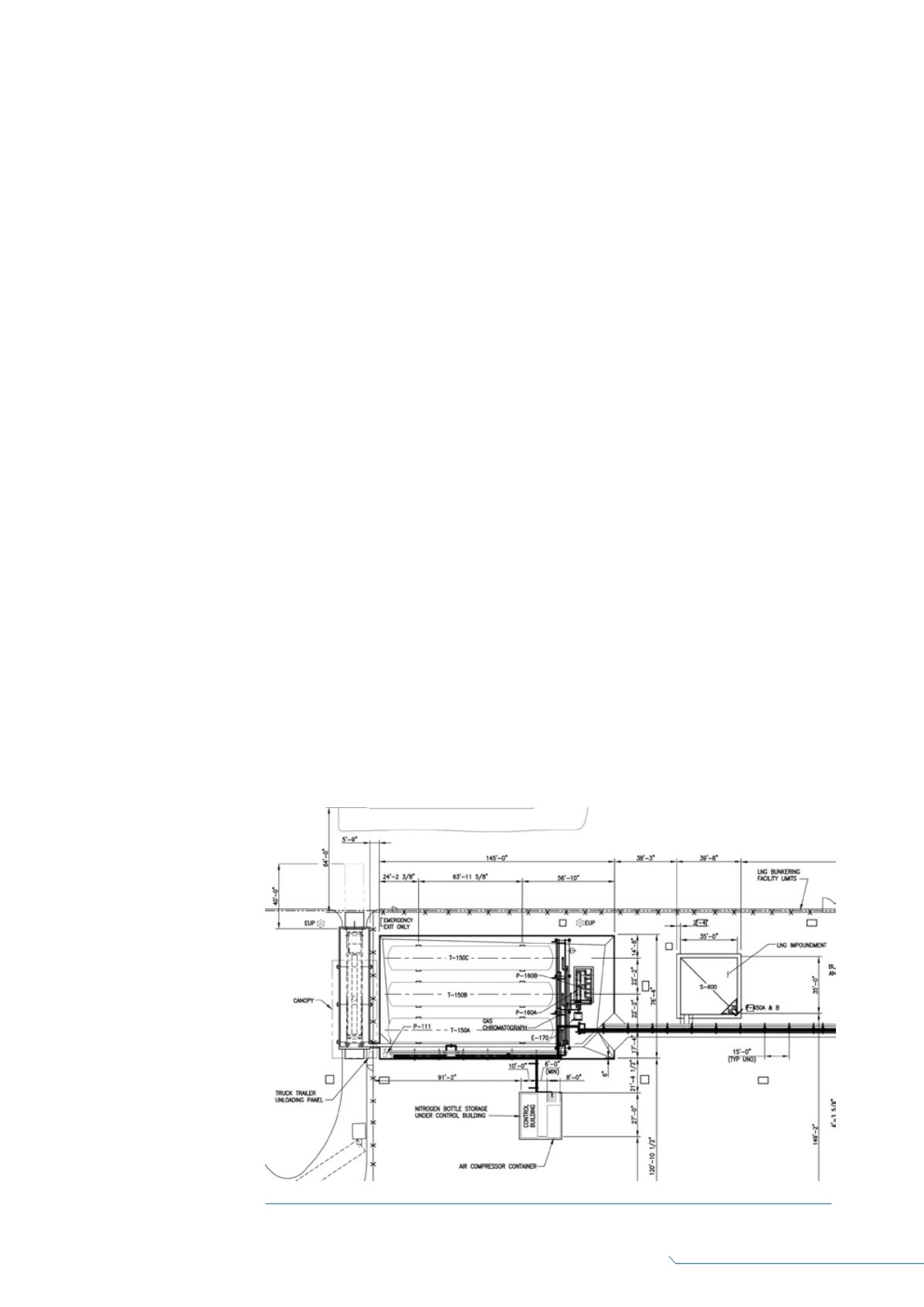

Figure 4.

The plot plan: LNG bunkering facility.