22

LNG

INDUSTRY

SEPTEMBER

2016

They will be equipped with vacuum-insulated tanks

installed below deck, and the fuel gas system will deliver

the natural gas to both high pressure main engines and

low pressure auxiliary engines.

United European Car Carriers (UECC) ordered two

dual-fuel, LNG-driven, pure car and truck carriers (PCTCs)

with 1A super Finnish/Swedish ice class with Kawasaki

Heavy Industries (KHI). The vessels will be constructed at

the NACKS shipyard in Nantong, China. They will be

capable of operating on LNG fuel or heavy fuel oil (HFO)

and marine gas oil (MGO), providing greater flexibility and

efficiency. They are the first PCTCs of their kind to be fitted

with LNG fuel propulsion systems, and can complete a

14 day round voyage in the Baltic using solely LNG fuel,

including main engine and auxiliary power generation. The

fuel gas systems will be capable of delivering natural gas

for both the high pressure MEGI engines and the low

pressure auxiliary engines. The LNG will be stored in a

Type C tank below deck with polystyrene insulation slabs.

Figure 4.

United European Car Carriers’ (UECC) pure car and

truck carrier (PCTC).

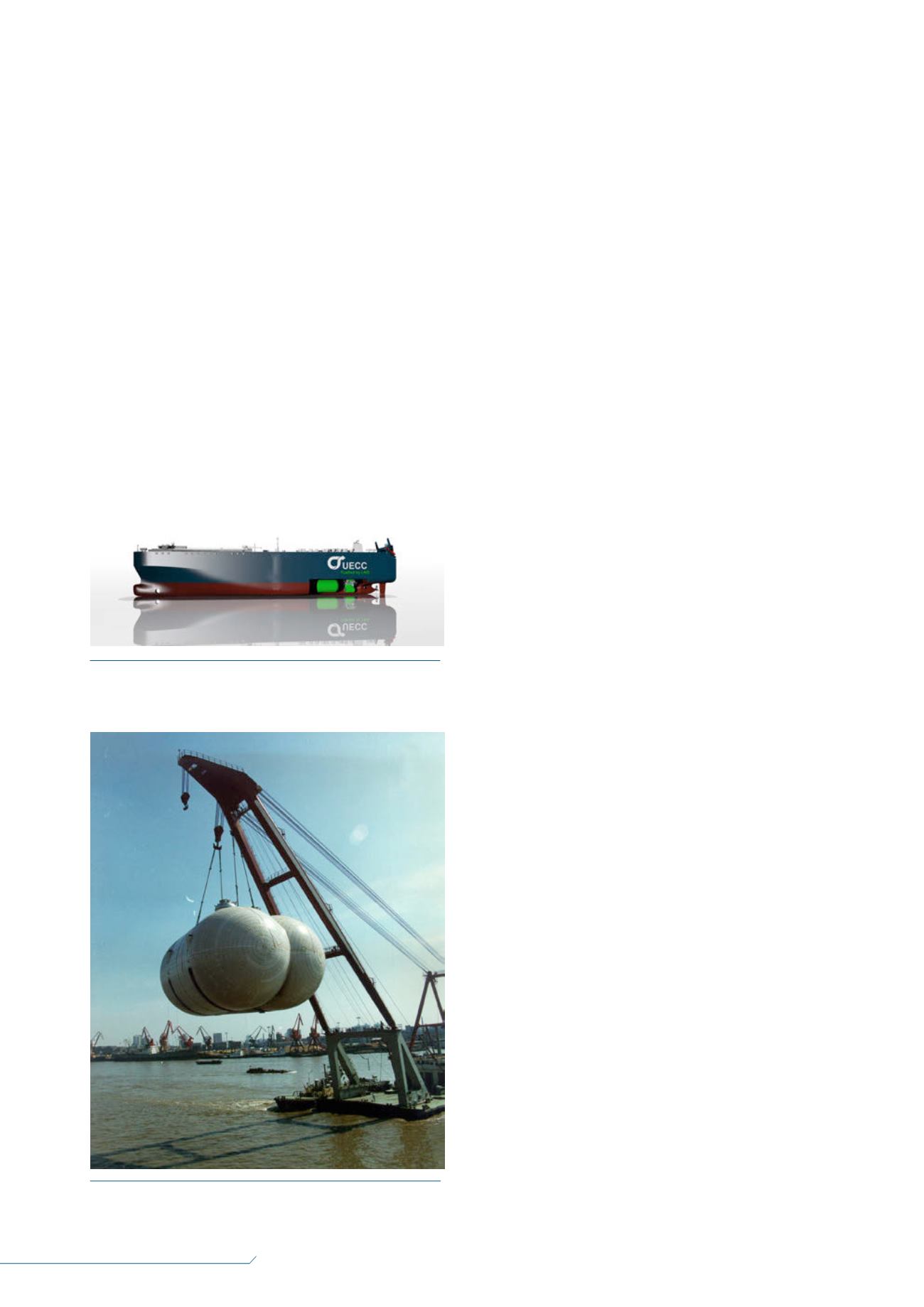

Figure 5.

Type C bilobe tank handling.

LNG containment system

The containment systems that store LNG on board ships

follow design principles familiar from gas carriers. The

three examples described in this article (except for the

Q-Max vessel, which had the LNG available from the

main cargo tank) clearly show the market trend. To

date, LNG as fuel applications in non-gas carriers have

used Type C pressure vessels only. There is a whole

range of technology solutions appearing in the market,

such as membrane tanks, Type B and Type A tanks.

Each solution may show its benefits in dedicated niche

applications, but have not been used to date.

A reliable choice for ship owners/shipyards,

emerging from a detailed analysis of the advantages/

disadvantages of each technology, is the pressurised

Type C tank solution, which offers the following

advantages:

Holding time: typically, the design pressure of

Type C tanks is set at 4 – 10 barg. These pressurised

vessels allow a longer holding time and further

flexibility to the running profile of the engines

considering periods of zero consumption.

Boil-off gas (BOG) management: the pressurised

vessel in combination with a simple BOG

compressor allows for the punctual control of the

gas flow and pressure inside of the LNG storage

tank. This technical solution provides the vessels

with great flexibility in terms of BOG management

and bunkering planning. Other tank concepts cannot

take pressure build-up of BOG, which leads to more

complicated gas handling systems and alternative

ways of burning the excess gas in a safe way.

Installation time: the tanks are delivered to the yards

ready for installation, with consequential advantages

in the planning for the retrofit or the newbuilding of

the vessel.

Investment: Type C tanks are relatively cheap

compared to other types of LNG storage tank

technologies.

Excellent safety records: Type C tanks are designed

to be inherently safe. They have been used as cargo

tanks for gas carriers for decades and no failure of

these tanks is known to date.

On the other hand, there is still no clear direction on

the choice between vacuum-insulated tanks and

foam-insulated tanks. In the small and medium scale

LNG carrier market, the foam-insulated tanks are the

only used solution. In the fuel gas system market, the

situation is slightly different due to smaller LNG

containment requirements. Vacuum insulation is still

considered to be a valuable solution. However, the

foam-insulated tanks offer weight advantages (due to

the double shell and perlite insulation, a

vacuum-insulated tank weighs twice as much as a

foam-insulated tank) and also give slightly less holding

time compared with the vacuum-insulated tanks. Where

the weight and investment are driven by cost,

foam-insulated Type C tanks are more widely used.