16

April 2020

drive MLA, and is ready to deploy this new technology to

its product range, including LNG.

With the same objective to improve efficiency and

reduce lifecycle costs, TechnipFMC has developed a

systematic MLA drone inspection method that has

performed more than 20 inspections since 2018.

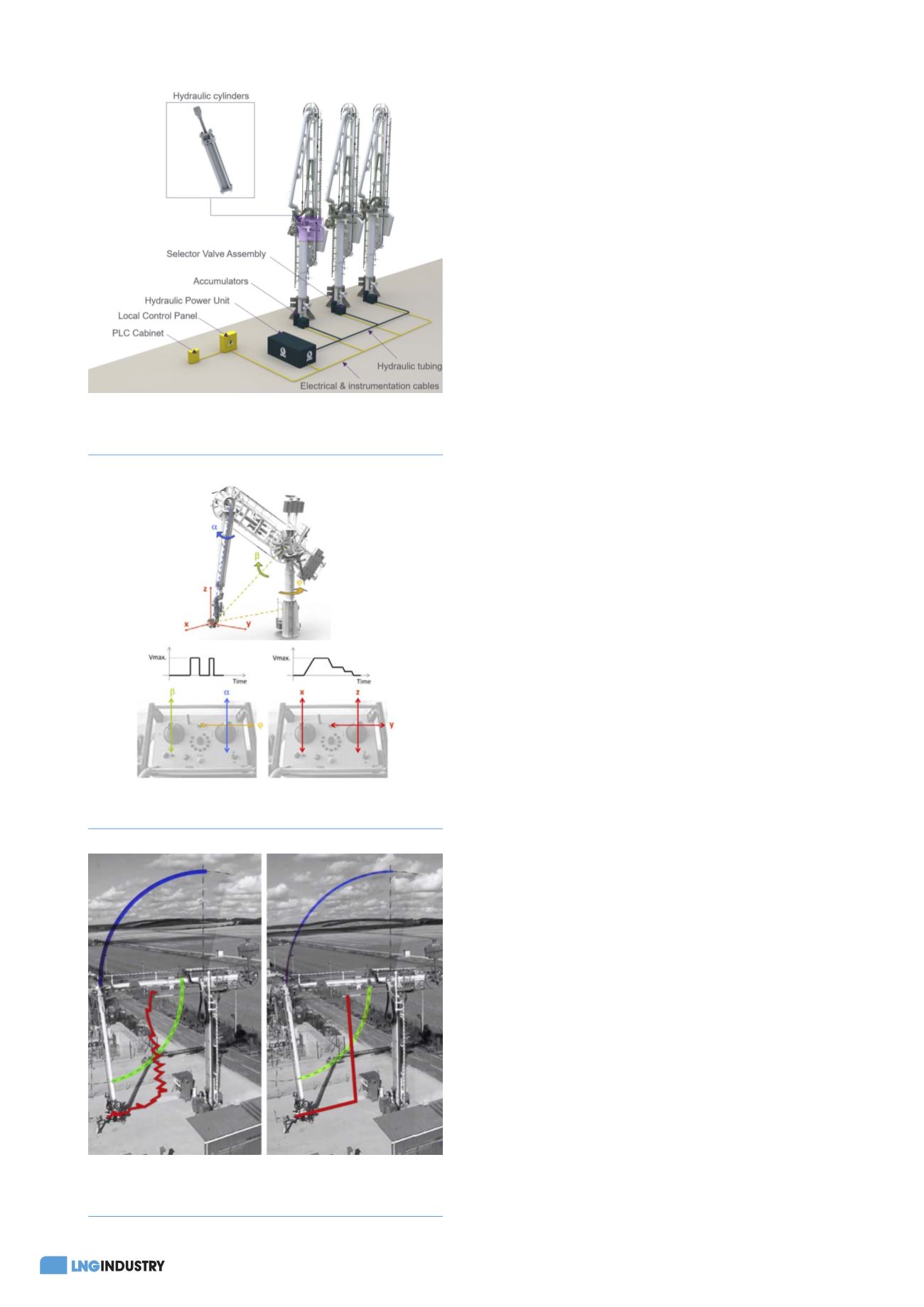

Conventional MLA control

A typical hydraulic arrangement of a bank of MLAs

(Figure 1) consists of an electric motor powering a

hydraulic pump in a hydraulic power unit (HPU) and

providing pressure hydraulic oil to a network of hydraulic

tubing and hydraulic valves, which is converted into

mechanical energy. Hydraulic accumulators may be used

to provide hydraulic energy in case of electrical power

blackouts.

The three main rotary motions of the MLA – slewing,

inboard luffing and outboard arm luffing – are actuated

with hydraulic cylinders. In the majority of cases, the HPU

provides a constant hydraulic flow to each actuator, which

is controlled with a solenoid type valve (i.e. ‘on’ or ‘off’). A

single-speed motion is then achievable (i.e. ‘stop’ or

‘full speed’). The HPU may be fitted with a two-level flow

setting (‘low’ and ‘high’), allowing the operator to

manoeuvre the MLA at a reduced single-speed motion.

Using a remote control unit, the operator controls

each rotary motion – slewing, inboard luffing and

outboard arm luffing – to move the MLA connection

flange at the desired position, e.g. for

connection/disconnection to or from the ship manifold. ln

practice, controlling the MLA connection flange position is

not easy, requiring intensive training for the operator.

Plus, as the motions are generated by actuators with the

on-off control at a fixed speed, the MLA movements are

jerky and inexact.

Terminals and refineries with high operator turnover

may come to a situation where operators have limited or

no training on loading arm operations. As such, equipment

damages may result with ill-trained operators controlling

the loading arms. For instance, seals could be damaged

from shocks with the ship’s flange or delays could result

from lengthy connection/disconnection operations.

Finally, when a ship is impacted by waves in an

exposed jetty or offshore, connecting a loading arm may

be nearly impossible. TechnipFMC supplies a field-proven

targeting system that enables connection/disconnection

operations under up to 2.5 m significant wave height (Hs)

conditions. However, the system is overkill for terminals

only slightly exposed to waves.

Improved control

With conventional on-off hydraulics, the operator directly

commands the MLA rotations – slewing, inboard arm

luffing and outboard arm luffing – to indirectly control

the MLA connection flange. TechnipFMC’s Easy Drive

allows the operator to directly command the rectilinear

motions of the MLA connection flange – right/left,

forward/back, up/down – and indirectly act on the

MLA rotations through a controller. Based on a current

MLA position provided by angular sensors measuring

the angle of each MLA rotation (slew, inboard arm and

outboard arm) and the targeted rectilinear direction and

Figure 1.

Conventional hydraulic arrangement of a bank of

marine loading arms (MLAs).

Figure 2.

Conventional (left) versus Easy Drive (right)

remote control unit.

Figure 3.

Conventional (left) versus Easy Drive (right) MLA

connection flange trajectories.