18

April 2020

speed, the controller calculates the required rotary motion

of each MLA rotation. Also, with Easy Drive, the operator

can tune the rectilinear speed by pushing more or less on

each remote control unit joystick (Figure 2). This allows

smooth displacement with virtually no oscillation of the

connection flange.

Easy Drive offers significant advantages over the

conventional on-off hydraulic control, especially for

exposed terminals experiencing ship wave induced

motions, or those with high operator turnover. Easy Drive:

z

Minimises operator’s training requirements as the

control is fully intuitive.

z

Minimises the risk of damage to the manifold flange

and seal, thanks to a smooth control of the MLA

connection flange motions.

z

Reduces connection time as the MLA connection

flange trajectories are straightforward (Figure 3).

z

Enables the MLA connection in more dynamic

conditions; tested at scale 1 using a test bench

reproducing the ship manifold motions.

All current MLA facilities can be upgraded to

Easy Drive with minimum hardware modifications and

downtime:

z

Replacement of slew, inboard arm and outboard arm

solenoid valves, generally located in a cabinet near

the base of each MLA by proportional valves.

z

Installation of slew, inboard arm and outboard arm

angular sensors (MLAs with position monitoring

systems need no upgrade).

z

Most of the remote control units (RCUs) in operation

are suitable for proportional control and do not need

to be replaced.

Easy Drive is patented and has been fully prototype

tested and witnessed by Lloyds Register, and can be

demonstrated in TechnipFMC Loading Systems’ facilities in

Sens, France. It has already been implemented on new

projects and several upgrading of existing installation are

currently ongoing.

Green and OPEX-effective

The e-MLA development was premised on maintaining

the same functionalities as the hydraulic MLA, but

changing hydraulic actuated functions to electric actuated

functions, i.e. arm manoeuvring, e-ERS and e-QC/DC.

A structured and risk-based approach was followed to

identify and address the novelty aspects of the e-MLA,

particularly where existing standards and guidelines were

not directly applicable and to develop a fit-for-purpose

design and operation philosophy. Off-the-shelf equipment,

induction gearmotors and motor controllers were selected

and integrated with particular attention paid to easing

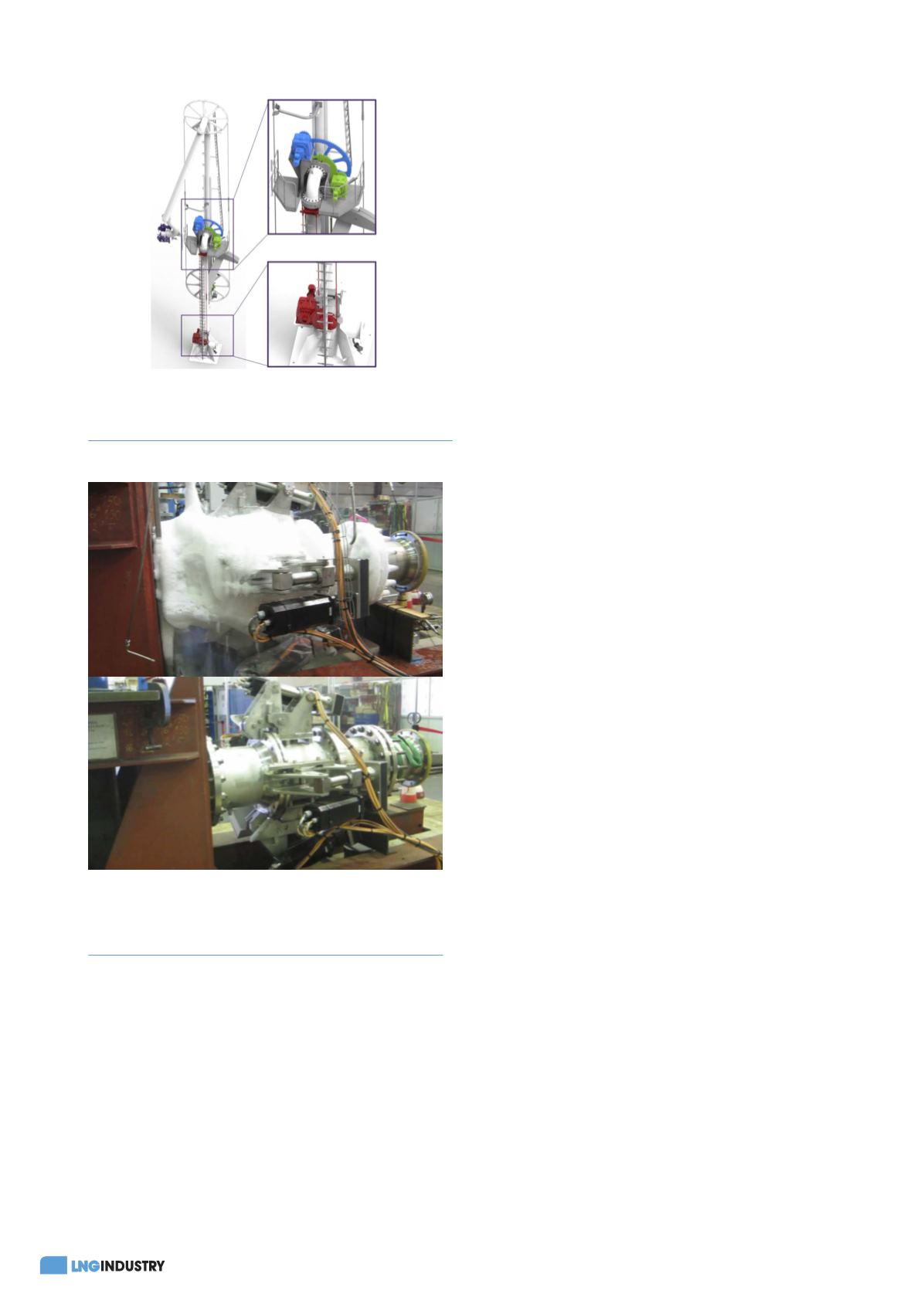

operator access to each actuator (Figure 4).

The ability to meet the expected performance standard

has been further confirmed through extensive prototype

tests of the new primary components – manoeuvring

actuator, e-QC/DC and e-ERS – under normal and

degraded operating conditions. A dedicated test bench

was used to apply designing load cases to the e-MLA

manoeuvring actuator (Figure 5), including manoeuvring

in balanced and unbalanced conditions, emergency

retraction and freewheeling. A climatic chamber was used

to perform tests under ambient temperatures up to -30°C.

These tests allowed the key parameters of the electrical

actuator (equivalent inertia, friction and damping) used in

the e-MLA finite element model to be characterised.

e-QC/DC and e-ERS have been prototype tested

against the same protocols used for hydraulic (‘Design and

Construction Specification for Marine Loading Arms’ –

3

rd

Edition 1999 – OCIMF and ISO 16904, Figure 5).

Compliance of the e-ERS with a SIL2 Safety Instrumented

Figure 4.

Electric MLA (e-MLA) manoeuvring actuators,

slew (red), inboard arm (blue) and outboard arm (green).

Figure 5.

Electric quick connect/disconnect coupler

(e-QC/DC) qualification test (ambient and cryogenic

temperatures).