36

With all of this to consider, the actual gas extraction

and processing seems somehow less challenging than the

logistics associated with delivering the LNG to European

and Asian markets. The LNG carriers and condensate

tankers will have to use the Northern Sea Route (NSR),

which is thick with ice for approximately nine months per

year. The vessels have to ensure safe, regular, and reliable

transportation year-round.

The number of transits during the open water season

(from July to November) along the NSR has increased

steadily from four vessels in 2010 to 71 vessels in 2013.

However, the traffic has remained static since then, at

approximately 40 ships per year.

In August 2010, the largest commercial gas condensate

shipment (71 000 t) was successfully carried out by

Novatek using the chartered tanker,

SCF Baltica

. In 2011,

Novatek was the primary user of the NSR, shipping nine

cargoes totalling more than 600 000 t of condensate from

Murmansk to Asia. On one occasion, it used the Suezmax

tanker,

SCF Vladimir Tikhonov

– the largest laden tanker to

transit the NSR. The number of large gas condensate

shipments through the NSR from 2010 (20 voyages) has

provided the necessary data to evaluate the feasibility of

using the NSR to ship LNG and gas condensate directly to

Asia during the summer months. By contrast, until today,

only two conventional LNG carriers have transited the NSR

during the open water navigation period in 2012 and 2013,

escorted safely by Russian nuclear ice-breakers.

The shipping side of the project

With the benefit of having this knowledge as a starting

point, and using some feedback from projects operating

year-round in the Barents Sea and Kara Sea (Varandey,

Prirazlomnoye, Dudinka) as a reference, the project’s

objective was to secure year-round export of LNG and

condensate (approximately 220 LNG cargoes per year,

when full production of three trains is reached).

Thus, the project’s shipping team had to consider the

following elements:

The development of an Arc7 ice-breaking LNG carrier

fleet, which would allow year-long shipments on an

independent basis (i.e. without ice-breaker assistance,

except for extreme or emergency situations) through

ice-covered areas towards Europe and, during summer,

using the NSR towards Asia.

The use of transshipment terminals for deliveries to

markets beyond the economical performance of the

ice-breaking LNG carriers. LNG cargoes would be

transferred from the Arc7 ice-breaking LNG carriers to

conventional LNG carriers, which would then deliver to

the final markets.

Using project marketing assumptions and simulations

for years of mild to severe ice conditions, the required total

fleet to export the LNG and condensates during the

plateau production of the plant (16.5 million tpy) was

determined to be:

15 Arc7 ice-breaking LNG carriers of 172 km

3

.

11 – 12 conventional LNG carriers (non ice-breaking, and

with smaller ice-class notation (ex: Arc4)), ranging from

155 km

3

to 165 km

3

.

Two Arc7 ice-breaking condensate tankers of 57 km

3

.

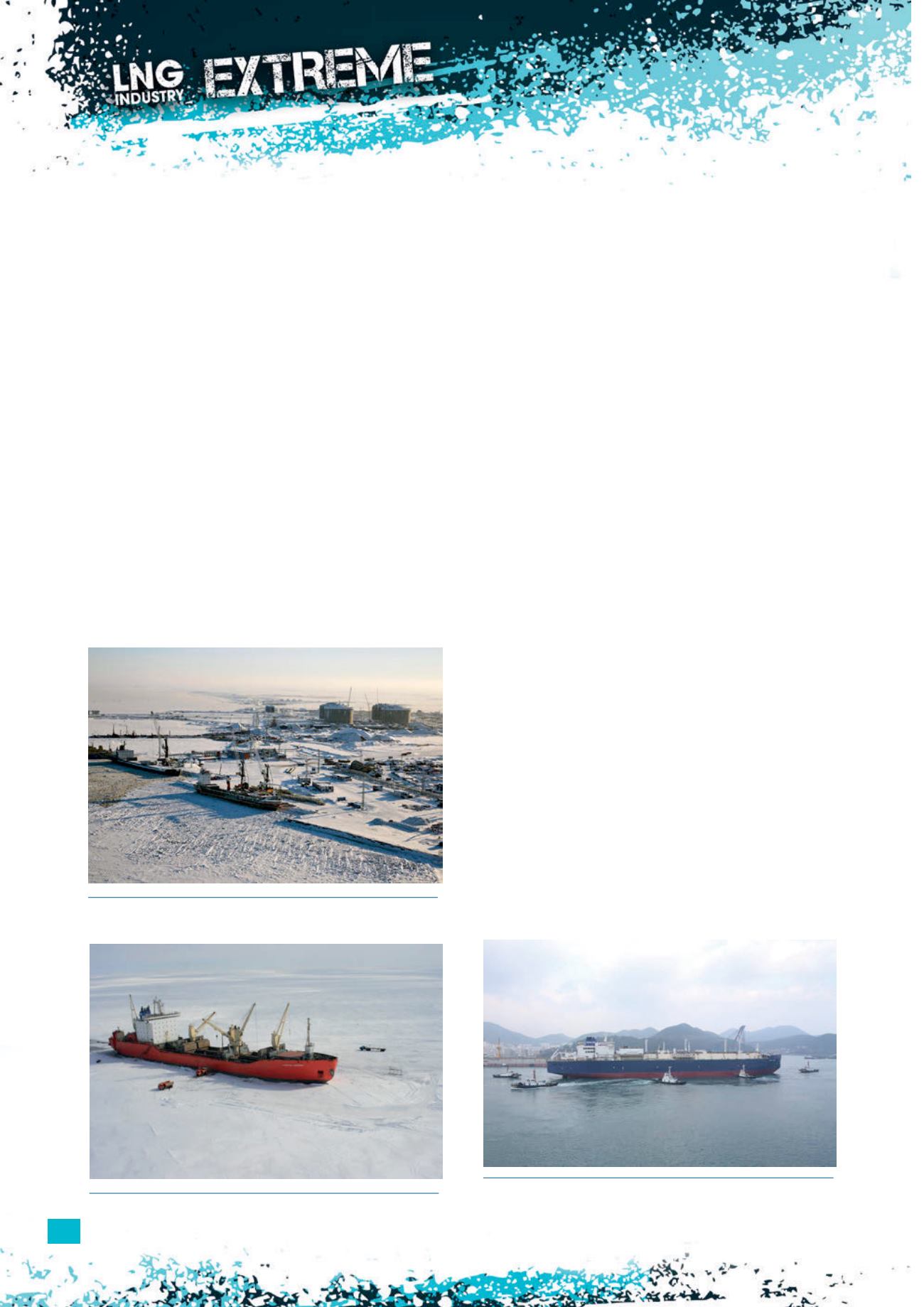

Figure 1.

The completed marine offloading facility (MOF).

Figure 3.

Launching of the first Arc7 ice-breaking LNG carrier at

Daewoo Shipbuilding & Marine Enginering’s (DSME) shipyard

(January 2016).

Figure 2.

Unloading onto ‘fast’ ice offshore at Sabetta, Russia,

with

Kapitan Danilkin – SA15

.