46

Modular, mammoth project

A key challenge of the project is not its spatial and technical

size or the material used, but rather project coordination across

national borders and cultural differences. Other important

factors include a strict time schedule between engineering input

and acceptance, as well as additional design modifications

that must be made in time for subsequent operations. Project

management, coordinated from Brühl, synchronised the

numerous interrelated process steps over several years, enabling

successful implementation.

From the initial planning phase to the

final acceptance

Prior to the start of the contract, HIMA’s experts and the basic

process control system (BPCS) supplier tested and validated

hardware and software functions. The company’s team dealt

primarily with the engineering and the design of the project. The

aimwas to clarify specifications in order to minimise subsequent

plan corrections and the additional time that this would involve.

Specific applications and various interconnection possibilities of

field devices were considered from an upstream perspective.

The onshore and offshore facilities and the pipeline are

connected to a total of 25 000 safety related input and output

points. Safe networking was implemented using the company’s

safeethernet protocol. Cybersecurity and network management

includes the installation of associated hardware and

components, e.g. smoke detectors in employee living

accommodation. Numerous workstations and servers, along

with an additional recovery system, are other components of the

safety solution.

In addition to ensuring safety, HIMax

®

safety controllers

provide uninterrupted systems operations, maximising system

availability and productivity. The safety systems comply with

IEC 61508 and IEC 61511 standards and meet SIL 3 and SIL 4

requirements. HIMA Planar4 controllers used on the project can

achieve SIL 4 – the highest possible safety standard – in

compliance with IEC 61508.

Worldwide coordination

Of the company’s five locations involved in the project,

Singapore is second only to Brühl in strategic significance.

In terms of worldwide coordination, Singapore offered the

shortest routes for all parties involved. In addition to INPEX

representatives, HIMA safety engineers and the control system

manufacturer, the three contractual partners for engineering,

procurement and construction (EPC) are represented on site. All

contractual partners have occupied one building

complex in order to communicate directly and

efficiently.

In Singapore, function tests of all safety systems

were performed on more than 1200 control

cabinets. In addition to the cabinets supplied by the

company, 800 cabinets were supplied by the BPCS

supplier and contractual partners. At the same time,

safety engineering activities were distributed over

three floors – one floor each for the

semisubmersible platform, the liquefaction facility

and the onshore facility. All facilities achieved 100%

acceptance in the prescribed time.

Prepared for the future

Changing with the times also meant developing

modular, commercial off-the-shelf (COTS)

systems. During large scale projects and under

extreme working conditions, COTS systems

ensure higher production quality, lower prices,

shorter implementation times and less effort at the

construction site.

Today’s new complexity applies to more than

technology. In the case of functional safety, the

operator must also comply with a multitude of

constantly changing laws, guidelines and standards.

A functional safety management (FSM) system

must be established over the entire lifecycle of a

project – from the initial design and

implementation, through to the production process.

Tailor-made safety solutions can provide the

operator with higher system availability and lower

maintenance costs, as well as better insurance

terms.

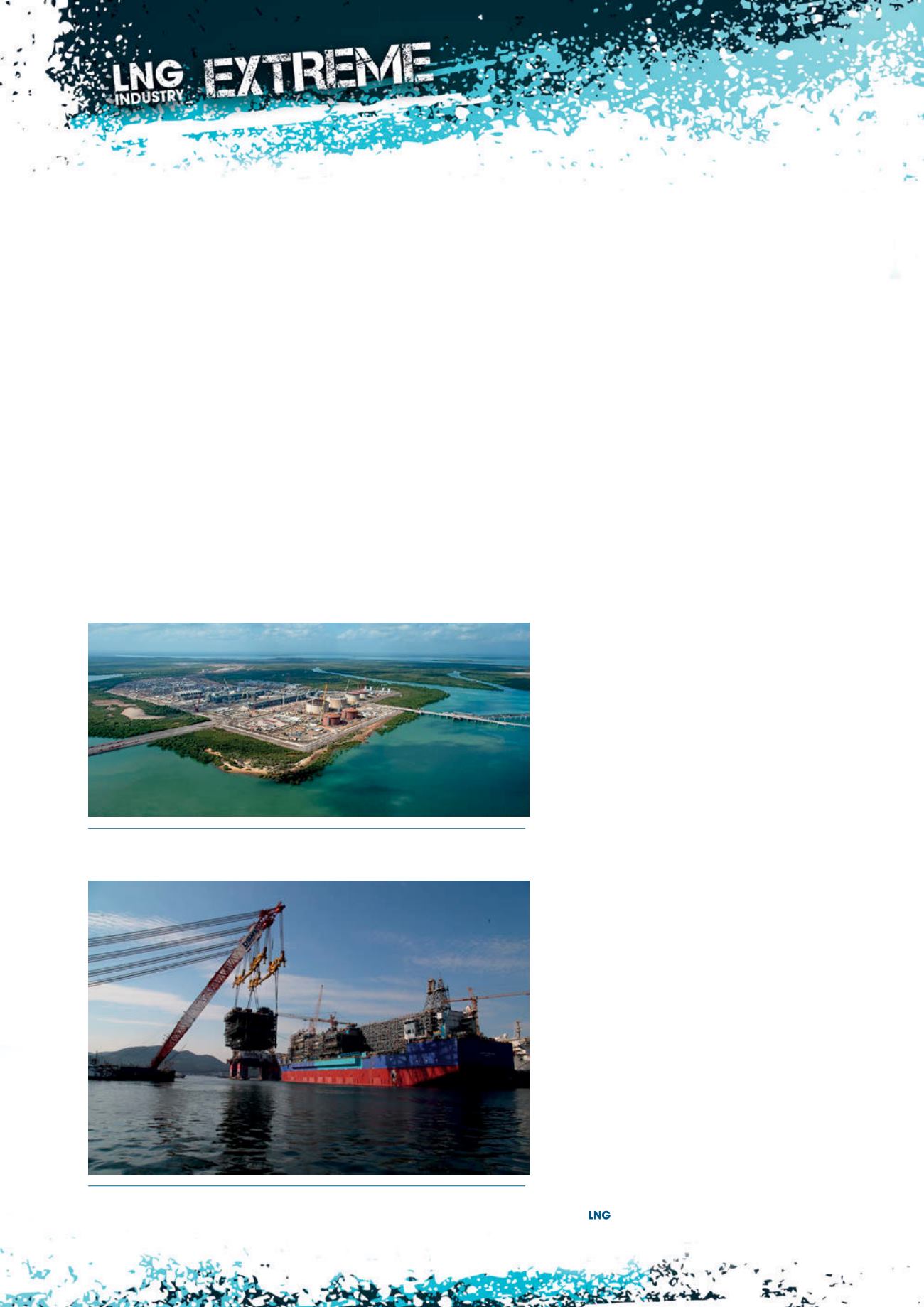

Figure 3.

The monoethylene glycol injection module is lifted and installed onto

the floating semisubmersible platform.

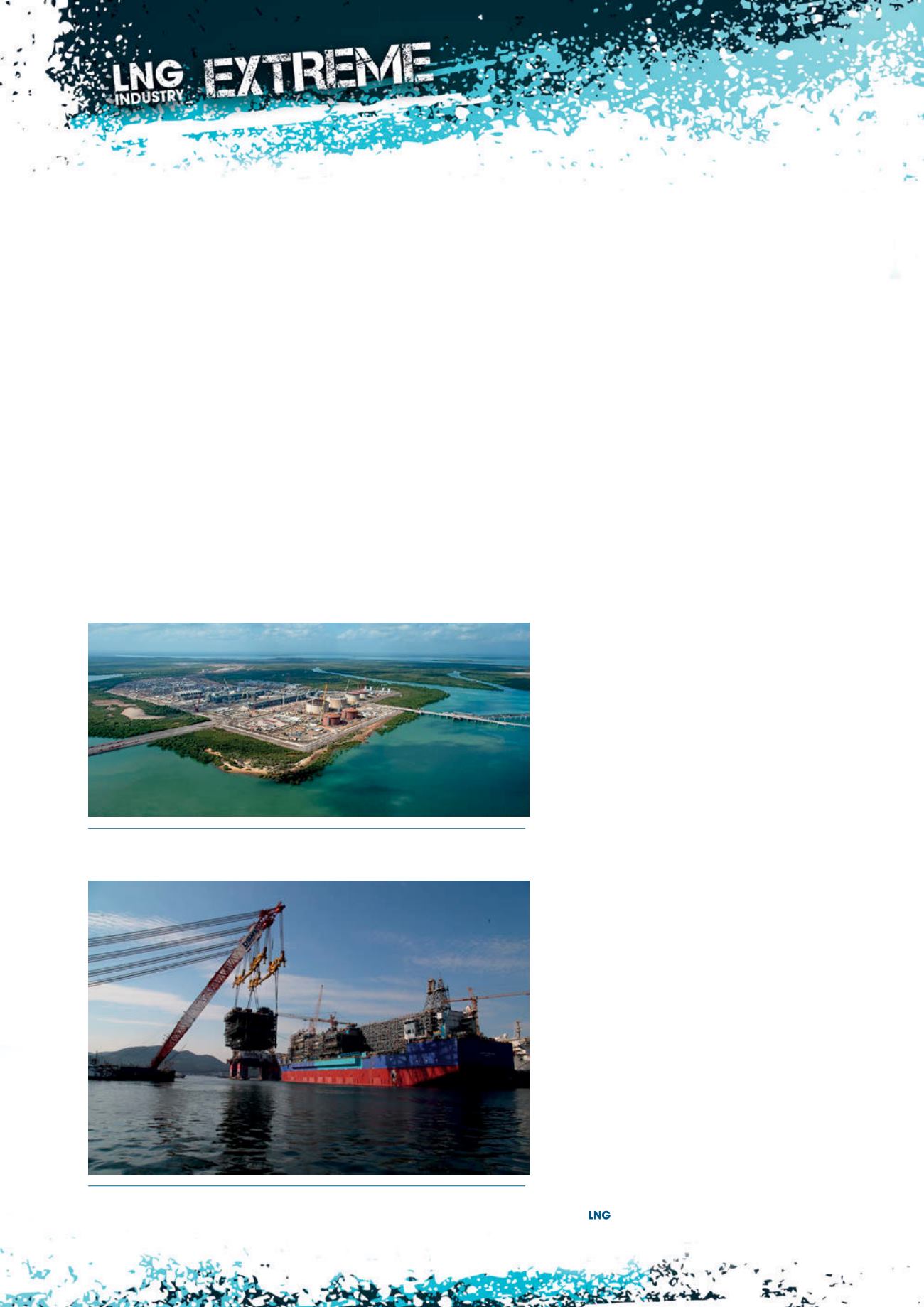

Figure 2.

Construction progress of the onshore facilities of the Ichthys LNG

Project in September 2015.