39

The cargo containment system

Feasibility studies were performed for three cargo containment

systems considered proven in Polar conditions (spherical

tanks from Moss, the membrane type from Gaztransport &

Technigaz (GTT), and the Self Supporting Tank Type B (SPB)

from IHI Corp.). However, the ultimate choice was determined

by the cargo containment system’s behaviour when subjected

to the vibrations induced by the conditions in the ice-breaking

LNG carrier’s ahead and astern modes of operation, to induced

fatigue, and to ice collision. One of the systems seemed to

require anti-rolling keels, which are not appropriate for ice. In the

end, the GTT NO96 GW (with GlassWool replacing the perlite

inside the plywood insulating boxes of the cargo containment

system) was chosen after additional studies and laboratory

testing, with a guaranteed boil-off rate of 0.13% vol./d.

Further to this, a series of ice and open water model tests

were performed in Finland, Canada and Germany to optimise the

design of the hull and the propulsion plant configuration, plus the

performance required by the technical specification (e.g. speed in

1.5 m thick level ice: 2 knots in ahead mode, 5 knots in astern

mode, and 19.5 knots in open water).

Greenlight for the ice-breaking

LNG carrier and condensate tanker

This investigative work resulted in the basic outline specification

for the Arc7 ice-breaking LNG carrier. Some of the technical

solutions were also applied to the condensate tanker. In

parallel, a prequalification, followed by a selection process, was

performed for potential shipyards and shipowners for the total

fleet of 15 Arc7 LNG carriers.

The final choice was awarded to Daewoo Shipbuilding &

Marine Engineering (DSME) for the construction of the full fleet

of 15 vessels plus the option for an additional vessel, and to four

experienced shipowners (Sovcomflot: one unit; Teekay: six units;

Dynagas: five units; and Mitsui O.S.K. Lines (MOL): three units), in

venture with Chinese partners.

The first ice-breaking LNG carrier was launched in

mid-January 2016 in Okpo, South Korea. A joint task force was

created between the ship operators and the charterer,

Yamal Trade, in order to maximise and share the experience of ice

navigation, and set a common approach for the future operations

along the NSR in the various disciplines of plan approval and

construction follow-up; health, safety, quality and environment

(HSQE); crewing and training; operations and depot spares; and, of

course, the application of the new Polar Code, which will enter

force in 2017.

The delivery of the first ship is scheduled for 4Q16 before the

start-up of the first liquefaction train at the plant. This will allow

crews to train and carry out ice trials in the Kara Sea’s actual ice

conditions.

In parallel, two Arc7 ice-breaking condensate tankers with the

double-acting system were ordered at the end of 2015 by two

other shipyards (Archtech in Finland, owned by Russian OSK, and

GSI in China) with the same owner, Dynagas, for delivery at the

beginning of 2018.

This is, with the ongoing chartering of other conventional

LNG carriers, the unique solution to export LNG and gas

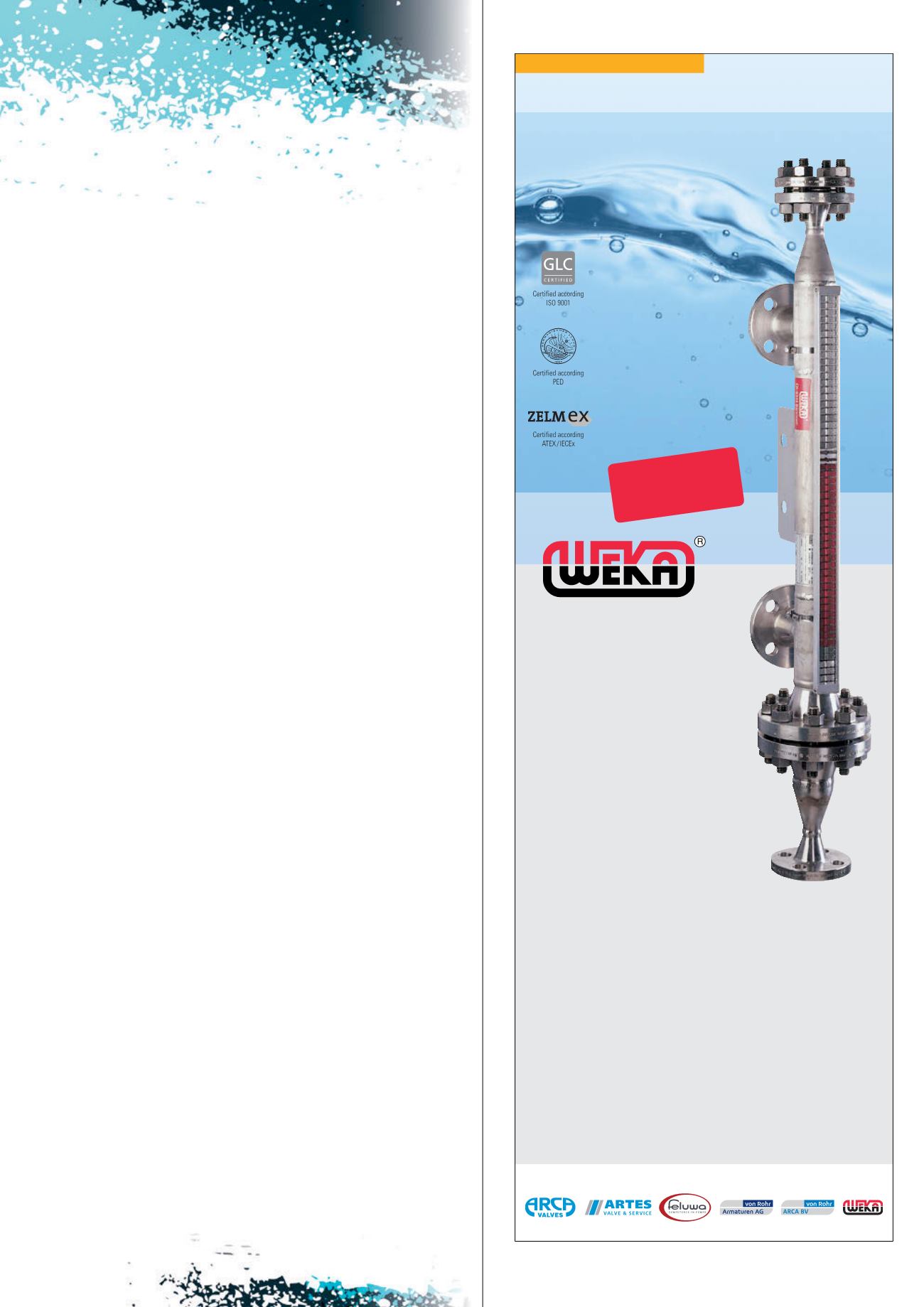

Meets the design standard of the

oil & gas, petrochemical, hydrocarbon

and LPG/LNG industries:

– Fully ANSI/ASME design

– Includes NACE requirements

Reliable level indication without external

power with three functions in one device:

– Liquid level indication

– Liquid level switch

– Liquid level transmitter

Equipment with optional bi-stable change over

or on/off switches and linear or non linear

transmitters (also as 2-wire systems

with 4…20 mA output, optional with HART

®

)

CE-conform and Ex-approval

For operating pressures from vacuum up to 400 bar and higher,

operating temperature from –196 °C up to +400 °C

Densities > 0.3 g/cm

3

Closed floats for condensing liquids up to 350 bar operating pressure

Construction in stainless steel grade 316/316L as standard.

Also possible in higher grades of stainless steel like 904L or Hastelloy

®

and Inconel

®

/Incoloy

®

alloys

Casing of indication rail in stainless steel

WEKA AG · Switzerland · Schürlistrasse 8 · CH-8344 Bäretswil

Phone +41 43 833 43 43 · Fax +41 43 833 43 49

·

ARCA Flow Group worldwide: Competence in valves, pumps & cryogenics

Level Measurement

Please visit us

a