26

LNG

INDUSTRY

JULY

2016

Increases in the richness of the gas reduce DNE’s advantage,

especially at higher capacities, while DMR becomes more

attractive.

Applicability range of FLNG

conversions

It has been seen that if the available layout space is limited

and the gas is average or lean, then DNE technology may

offer a higher capacity for a fixed available layout area. In

particular, a single tanker conversion offers approximately

6000 – 8000m

2

available, while a double tanker conversion, such

as SBMOffshore’s FLNG Twin Hull

TM

concept, offers approximately

12 000 – 15 000m

2

, resulting in a production capacity of

approximately 0.6 – 0.8million tpy and 1.5 – 1.7million tpy,

respectively.

Conclusion

The main application of DNE for FLNG is for projects that fall in the

mid scale range and that do not require fractionation. However,

this technology loses its advantage when fractionation is required.

Looking at CAPEX, the DNE process is cheaper thanMR

processes, mainly due to differences in safety gap requirements,

which impact hull size. However, under certain conditions, such as

rich gas and premium LPG prices, the higher CAPEX can be justified

by higher revenues.

For near-shore applications, fractionation is typically not

required as themake-up refrigerant can be bunkered. In this case,

the SMRmay also be applied to lean gas.

In the small scale capacity range (below 1 million tpy), an

FLNG investment is only viable for near-shore applications where

a tanker conversion or a simple barge is used. When moving

further offshore, the minimum CAPEX requirement is such that

the revenues from such small plants will hardly justify the

expenditure.

In themid scale capacity range (1 – 2million tpy), and inmild to

moderate environmental conditions, an FLNG conversionmay

represent themost attractive solution when dealing with lean or

average gas. If capacity is higher than 2million tpy, or the gas is

rich, then the ideal solution can be a newbuild hull and anMR

process.

In the large scale capacity range (above 2million tpy) requiring

four refrigeration compressor sets, DMR becomes a more

economical choice. At this large scale though, adverse weather

conditions can lead to costly hull andmooring system

requirements, which canmake CAPEX a financially limiting factor,

even if the economies of scale provide for a profitable

performance.

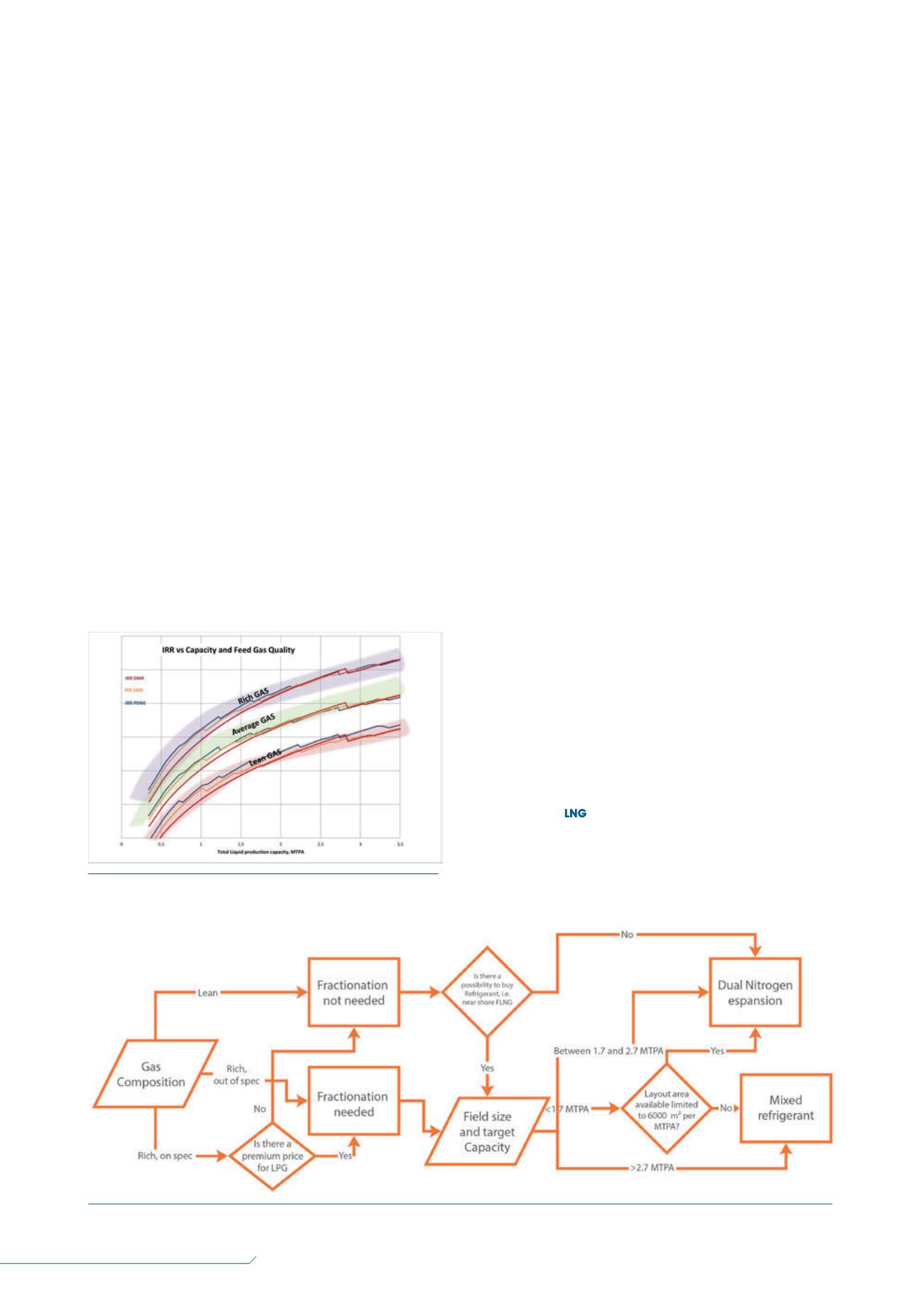

Figure 8 aims to summarise the findings of this study, but it is

difficult to make generalisations. The main conclusion is that each

individual FLNG project must take into consideration a range of

specific factors, including market conditions, gas quality, the

environment, and client specific targets, before selecting the best

solution for the project.

Overall, SBMOffshore concludes that DNE will typically be

preferred for the following types of projects:

Lean gas offshore.

Average gas offshore, where there is no immediate LPG

market.

Conversion projects, where deck space is limited and LPG

storage is not readily available.

Small capacity plants (<2million tpy).

On the other hand, SMR and DMRwill typically be preferred

for the following:

Average to rich gas projects offshore, where fractionation is

required.

Large capacities (>2million tpy).

Lean gas near-shore, wheremake-up refrigerant can easily be

bunkered.

Reference

1. CRIMINISI, F., WIJNGAARDEN, W., and

DAHOE, S., ‘FLNG Hazard Perception’,

LNG Industry

,

(November/December 2014), pp. 31 – 34.

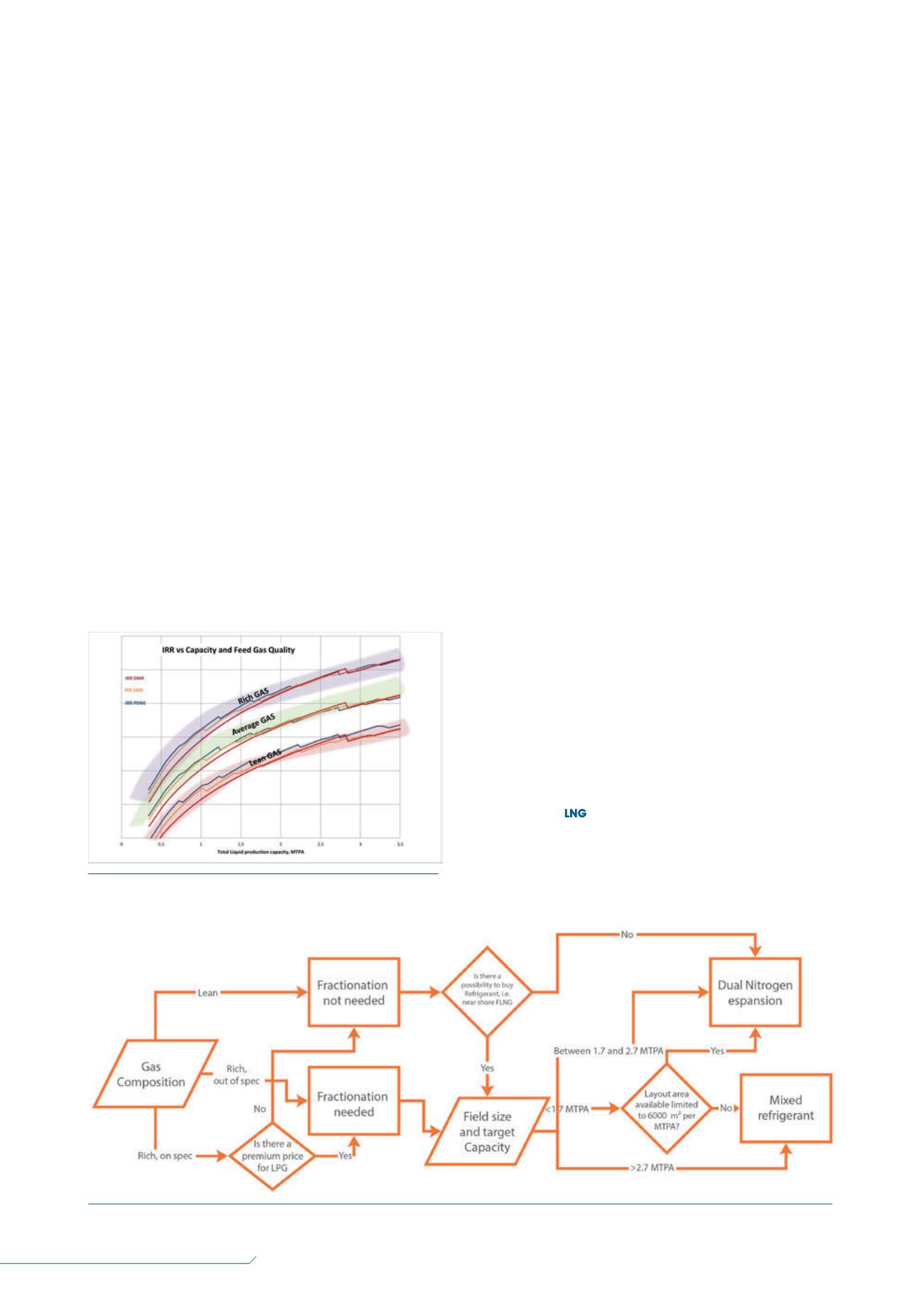

Figure 7.

Internal rate of return (IRR) vs production capacity for

different liquefaction technologies.

Figure 8.

Proposed algorithm for the technology selection for FLNG.