54

LNG

INDUSTRY

OCTOBER

2016

High capacity vane efficiency

Standalone single and double pocket vane performance is

typically in the range of 15 – 50

µ

m. A mesh type preconditioner

enhances the mist eliminator performance. This design is

often sufficient to meet the common performance target of

the removal of 99.9% of 10

µ

m

droplets and larger, but only

with the inclusion of the preconditioner, which operates in the

flooded regime, saturated with liquid. Mist-laden gas enters the

preconditioner, which intercepts and collects the fine droplets.

The collected droplets coalesce into much larger droplets. The

larger droplets are entrained into the vane mist eliminator and

removed.

The total flange-to-flange pressure drop for this application is

less than 0.75 psi.

The difference between the gas and liquid density provides

the driving force for the collection of suspended droplets. The

physical properties of the liquid – particularly density, viscosity

and surface tension – have a significant impact on the retention of

collected liquid.

For example, an exceptionally high viscosity liquid will drain

slowly, which will reduce the total liquid load that the vane

pockets may accept before filling completely. The vane

performance decreases dramatically if the drain pockets are full of

viscous liquid or solid fouling. Since liquid viscosity is directly

related to themaximumdrainage rate, the designer should

consider splitting the vane bank into shorter vertical sections with

intermediate drainage troughs. Themaximumheight of a single

vane pack should be between 4 and 8 ft.

Another example is a low surface tension liquid. Here, the

liquid droplets impinge upon the vane surface andmay shatter,

sending small droplets that are difficult to capture back into the

gas stream. The filmof liquid that remains on the vane surface is

also at risk of shearing into the gas stream. Gas load factors are

empirical values developed by themanufacturers for their own

specific products. It is important to reduce the design k-value if the

liquid surface tension is exceptionally lower than the test liquid

used to develop the data.

Vanes experience a sharp decline inmist removal efficiency

upon flooding. Once the gas velocity is sufficient to shear liquid

from the blade surface, or the liquid drain path is choked, liquid

can no longer reach the drain trough. This means that the liquid

exits the vane with the discharging gas, in the formof

re-entrainment.

A new approach

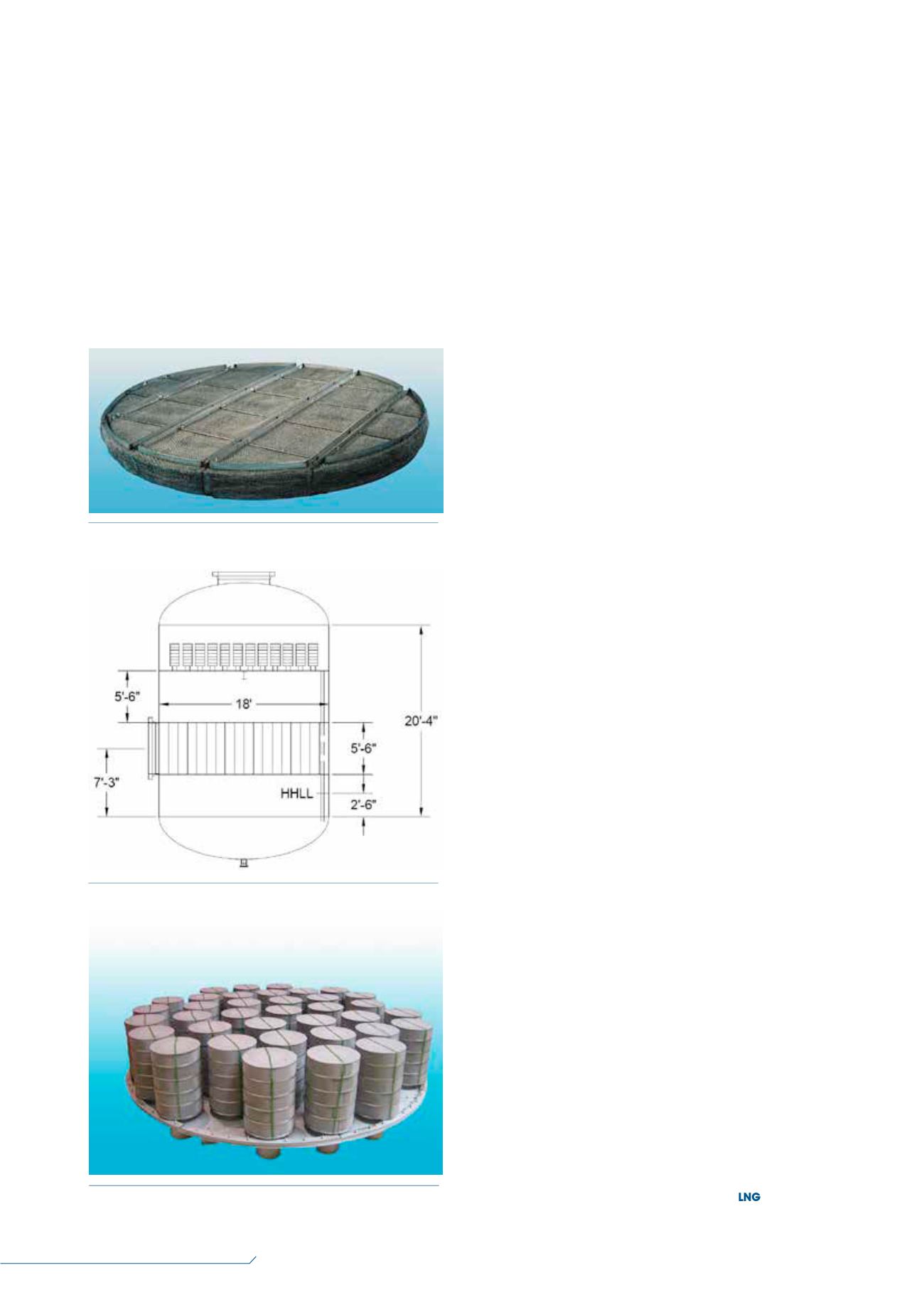

A bank of cartridgemist eliminators is another option. The

Sulzer MKSMulti Cassette

TM

mist eliminator uses stacked

cassettes in parallel to providemore flow area than the vessel

cross section. The design gas load factor is similar to a mesh pad,

but the outer surface area of each cassette can be considered. The

required flow area can be achieved with 864 cassettes that will be

stacked on a minimumnumber of individual cylinders.

In this example, themist eliminator requires a similar diameter

as the twin box vane arrangement, but reduces the required vessel

height by 50 in. compared to the twin box vane arrangement.

To fit within an 18 ft dia. vessel with a 3 in. wide perimeter ring,

the cylinders aremounted on a support tray with a centre support

beam, and the support tray is split into panels to pass through the

vessel manway.

TheMulti Cassettemist eliminator can provide collection

efficiency of 99.9%of 8 – 10

µ

m droplets. Amesh preconditioner

may augment efficiency. Unlike vanes, there is no limitation on

operating pressure.

The total flange-to-flange pressure drop for this application is

less than 1.0 psi.

This design has been successfully retrofitted into existing

knock out drums without welding. The supplier designed the

internals to utilise the existing support ring and fit within the

available vertical space. One of the retrofit vessels has been in

operation since 2009.

Sulzer uses a thorough design review for all separator

optimisation operations, including several low pressureMR

suction knock out drums currently in fabrication.

Figure 5.

Sulzer MKS Multi Cassette mist eliminator.

Figure 4.

Sulzer MKS Multi Cassette elevation.

Figure 3.

Sulzer knitmesh mist eliminator.