52

LNG

INDUSTRY

OCTOBER

2016

There are also practical considerations for the vessel

arrangement. A 200 ft

2

vane cannot be expected to operate at

peak efficiency if it is 5 ft wide and 40 ft tall. Such an arrangement

would almost certainly have poor flow distribution and be prone

to unstable operation. In general, holding dimensions within a

2:1 ratio is sufficient to promote uniform flow distribution.

The gas velocity within themain body of the vessel should not

exceed the design gas velocity of themist eliminator, as doing so

increases the risk of flowmaldistribution.

If an 18 ft dia. vessel is considered, and reasonable allowances

for the housing installation aremade, then a single vertical bank

would be approximately 13 ft tall.

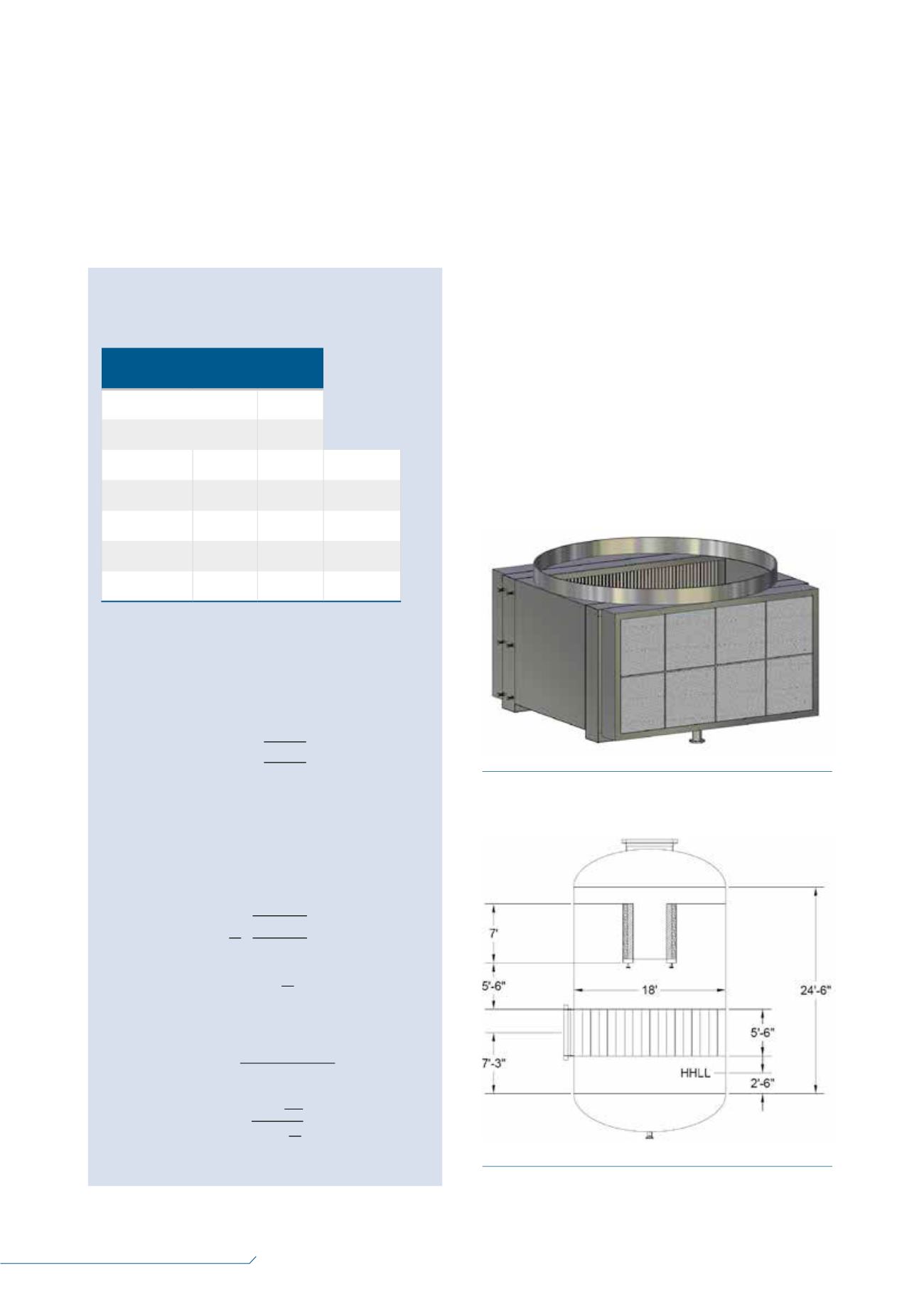

Alternatively, the vane bank may be split into two 7 ft tall

parallel banks, as shown in Figure 1. This twin box arrangement

requires an 18 ft dia. x 24 ft x 6 in. high vertical vessel, shown in

Figure 2. This is a significant reduction from the 34 ft dia. traditional

design. A vane type inlet device has been included as a

recommended practice for this example. The detailed discussion

of inlet device type selection and design is outside the scope of

this article.

There are dimensional guidelines that relate the

disengagement space between the high high liquid level (HHLL),

inlet device, vane pack entrance, inlet chord area, outlet area, and

above the vane to the vessel outlet.

It is possible to retrofit an existing vessel with this

arrangement, but doing so frequently requires welding the

housing structure to the shell. The vertical height required often

makes this option impossible. The vane will not fit within the

space available.

The twin box arrangement provides excellent capacity and

mist separation efficiency, but requires significant vertical height.

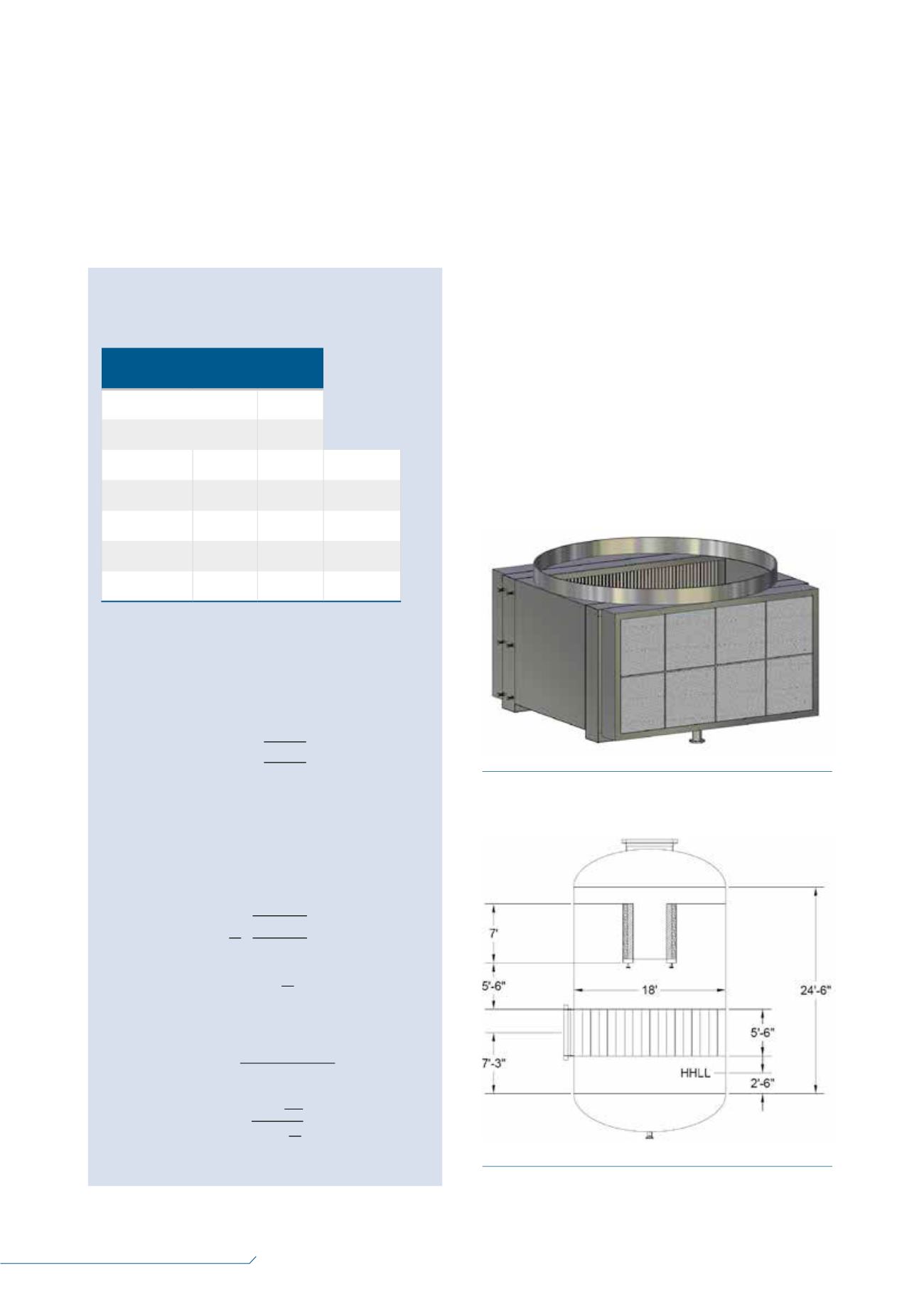

Figure 1.

Sulzer twin box vane with preconditioner.

Figure 2.

Twin box vane arrangement.

Low pressure MR suction

knock out

Table 1.

Low pressure suction knock

out design basis

Operating temperature

-45°C

Operating pressure

35.5 psia

Gas

Liquid

Units

Mass flowrate 3 million 30 000 lb/h

Density

0.30

36.2

lb/ft

3

Viscosity

0.008

0.20

cP

Surface tension N/A

15

Dyne/cm

Performance targets:

•

Removal of 99% of 10

µ

m droplets.

•

Pressure drop: 1.0 psi maximum.

Traditional design practice uses the Souders-Brown

equation to define a maximum design velocity:

ch 24, 2016

ign 2Stimization oI a /ow 3ressure Mi[eG 5eIrigerant Suction KnocN 2ut 'rum

Low Pressure Mixed R frigerant Suction Drum receives refrigerant vapor flow from the main

genic heat exchanger and sep rates entrained liquids to protect the mixed refrigerant

pressor from damage. Operationally, the LP MR Suction Drum is characterized by high gas

me with low liquid flow, ypically less than 1% by mass. The high gas flow drives the size

irements of the vessel, and as a result, these vessels tend to be quite large. This service is a

d candidate for optimization through careful selection of process internals.

sider the following design basis.

LP MR Suction Knock Out Design Basis

rating Temperature

-45°F

rating Pressure

35.5 psia

Gas

Liquid

Units

s Flow Rate

3,000,000

30,000

Lb / h

sity

0.30

36.2

Lb / ft

3

osity

0.008

0.20

cP

ace Tension

N / A

15

Dyne / cm

ormance Targets

oval of

99

% of

10

Micron droplets.

sure Drop

1.0 psi

Max

itional design practice uses th Souders-Brown quation to define a maximum design velocity:

ݒ

= ݇ඨ

ߩ

െ

ߩ

ீ

ߩ

ீ

GPSA Data Book section on Separators recommends that the gas load factor k = 0.28 ft. / s

compressor suction scrubber in a vertical drum with a wire mesh mist eliminator. We then

titute the gas and liquid density from above and find the maximum design velocity is

ݒ

= 0.2ͺ ඨ 36.2 െ 0.3 0.3

ݒ

= 3.063

minimum required flow area is

= ܸ݈

ݑ

݉ ݅ܿ ݈

ݓ

ܸ ݈ܿ݅

ݕ

The GPSA Data Book section on Separators

recommends that the gas load factor k = 0.28 ft/sec. for a

compressor suction scrubber in a vertical drumwith a wire

mesh mist eliminator. Next, substitute the gas and liquid

density from above to find that the maximum design

velocity is:

24, 2016

n 2Stimization oI a /ow 3re sur Mi[eG 5 Irigerant Sucti n KnocN 2ut 'rum

ow Pressure Mixed Refrigerant Suction Drum receives refrigerant vapor flow from the main

enic heat exchanger and sep rates entrained liquids to protect the mixed refrigerant

ressor from damage. Operationally, the LP MR Suction Drum is characterized by high gas

e with low liquid flow, typically less than 1% by mass. The high gas flow drives the size

ements of the vessel, and as a result, these vessels tend to be quite large. This service is a

candidate for optimization through careful selection of process internals.

der the following design basis.

LP MR Suction Knock Out Design Basis

ting Temperature

-45°F

ting Pressure

35.5 psia

Gas

Liquid

Units

Flow Rate

3,000,000

30,000

Lb / h

ty

0.30

36.2

Lb / ft

3

sity

0.008

0.20

cP

e Tension

N / A

15

Dyne / cm

mance Targets

val of

99

% of

10

Micron droplets.

ure Drop

1.0 psi

Max

ional design practice uses the Souders-Brown equation to define a maximum design velocity:

ݒ

= ݇ඨ

ߩ

െ

ߩ

ீ

ߩ

ீ

PSA Data Book section on Separators recommends th t the gas load factor k = 0.28 ft. / s

ompressor suction scrubber in a vertical drum with a wire mesh mist eliminator. We then

tute the gas and liquid density from above and find the maximum design velocity is

ݒ

= 0.2ͺ ඨ 36.2 െ 0.3 0.3

ݒ

= 3.063

inimum required flow area is

= ܸ݈

ݑ

݉ ݅ܿ ݈

ݓ

ܸ ݈ܿ݅

ݕ

ch 24, 2016

ign 2Stimization oI a /ow 3ressure Mi[eG 5eIrigerant Suct on KnocN 2ut 'rum

Low Pressure Mixed Refri erant Suction Drum receives refrigerant vapor flow from the main

genic heat xchanger and separates ent ained liquids to protec the mixed refrigerant

pressor from damag . Operationally, the LP MR Suction Drum is characterized by high gas

me with low liquid flow, typically ess than 1% by mass. The hig g s flow drives the size

irements of the vessel, and as a result, these ves els tend to be quite la g . T is service is a

candidate for optimization through careful selection of proc ss internals.

sider the following design basis.

LP MR Suction Knock Out Design Basis

rating Temperature

-45°F

rating Pressure

35.5 psia

Gas

Liquid

Units

s Flow Rate

3,000, 00

30,000

Lb / h

sity

0.30

36.2

Lb / ft

3

osity

0.008

0.20

cP

ace Tension

N / A

15

Dyne / cm

ormance Targets

oval of

99

% of

10

Micron droplets.

sure Drop

1.0 psi

Max

itional design practice uses the Souders-Brown equation to define a maximum design velocity:

ݒ

= ݇ඨ

ߩ

െ

ߩ

ீ

ߩ

ீ

GPSA Data Book section on Separators recommends that the gas load factor k = 0.28 ft. / s

compressor suction scrubber in a vertical drum with a wire mesh mist eliminator. We then

titute the gas and liquid density from above and find the maxi um design velocity is

ݒ

= 0.2ͺ ඨ 36.2 െ 0.3 0.3

ݒ

= 3.063

minimum required flow area is

= ܸ݈

ݑ

݉ ݅ܿ ݈

ݓ

ܸ ݈ܿ݅

ݕ

The minimum required flow area is:

rch 24, 2016

sign 2Stimizati n oI a / w 3 essure Mi[eG 5 Irigerant Suctio K ocN 2ut 'rum

Low Pressure Mixed Refrigerant Suc io Drum receives refrigerant v por flow from the main

ogenic heat exchanger and sep rates e trained liquids to prote t the mixe efrigerant

press r from amage. Operationally, the LP MR Suc ion Drum i charact rized by high gas

u w th low liquid flow, typically less than 1% by mass. Th high gas flow driv s th ize

uirements f the vessel, and as a result, these vessels tend to be quite large. This service is a

d candidate for optimization through careful selection of process internals.

nsider the following design basis.

LP MR Suction Knock Out Design Basis

erating Temperatur

-45°F

erating Pressure

35.5 psia

Gas

Liquid

Uni s

s Flow Rate

3,0 ,000

30, 00

Lb / h

nsity

0.30

36.2

Lb ft

3

cosity

0.008

0.20

cP

rface Tension

N / A

15

Dyne / cm

rformance Targets

moval of

99

% of

10

Micron droplets.

ssure Drop

1.0 psi

Max

ditional design practice u es the S uders-Brown equation to define maximum design velocity:

ݒ

= ݇ඨ

ߩ

െ

ߩ

ீ

ߩ

ீ

GPSA Data Book section on Separators recommends that the gas load factor k = 0.28 ft. / s

a compressor suction scrubber in a vertical drum with a wire mesh mist eliminator. We then

stitute the gas an liquid density from above and find the maximum design velocity is

ݒ

= 0.2ͺ ඨ 36.2 െ 0.3 0.3

ݒ

= 3.063

minimum required flow area is

= ܸ݈

ݑ

݉ ݅ܿ ݈

ݓ

ܸ ݈ܿ݅

ݕ

ry 24, 2016

Optimization of a Low Pressure Mixed Refrigerant Suction Knock Out Drum

of 7

= 2777

3

3.063

= 907

2

resultant vessel diameter is nearly 34 ft.! There must be a better solution.