30

LNG

INDUSTRY

OCTOBER

2016

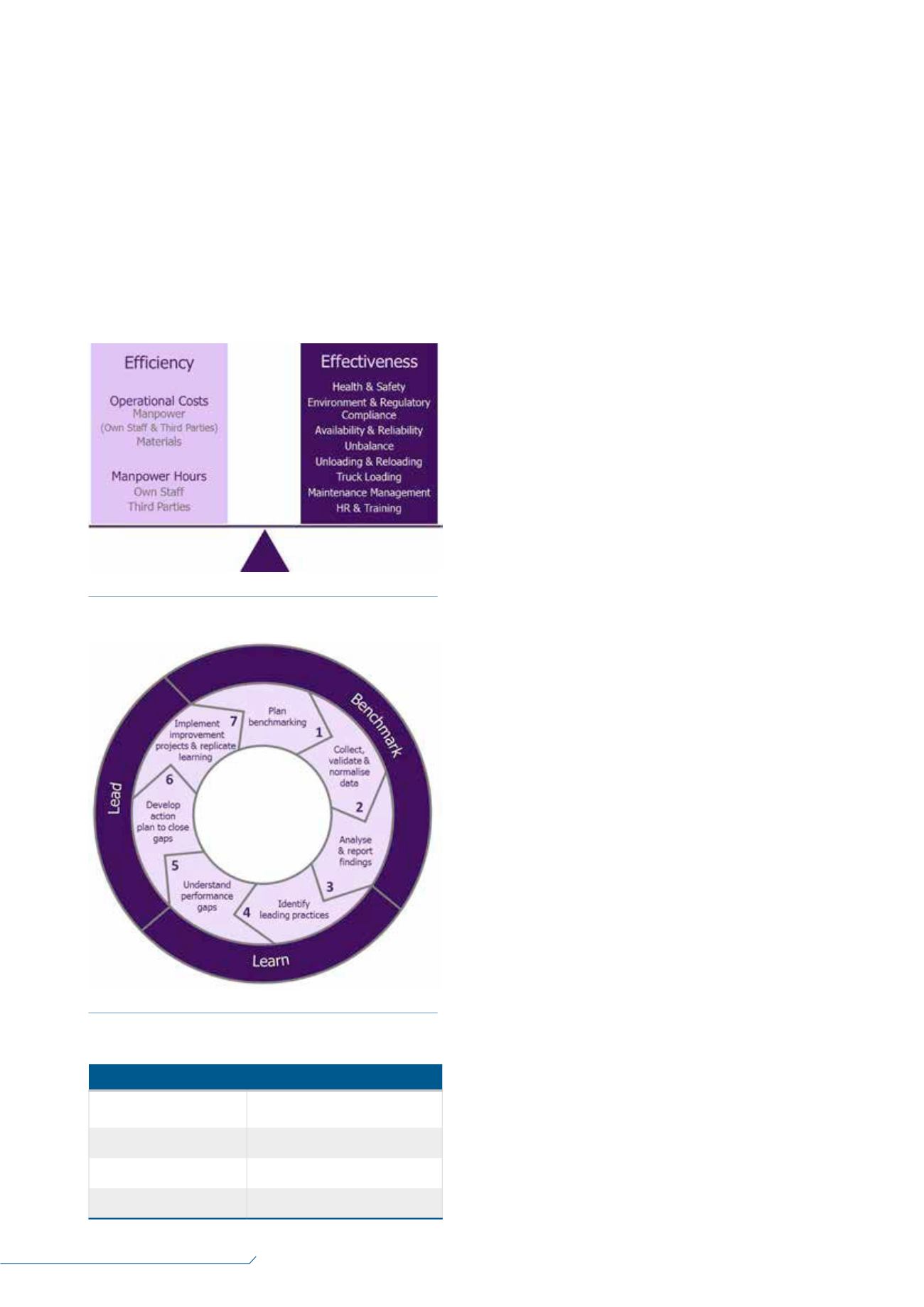

The scope of the benchmarking includes a detailed

analysis of both the efficiency and effectiveness of terminal

operations, maintenance and related support functions

(Figure 1). Efficiency considers OPEX for manpower and

materials, as well as manpower time expended. Costs and

manpower time for each terminal are analysed for each

performance-driving area, including the following:

Operations.

Maintenance.

Functional support services.

Energy consumption.

Effectiveness is determined by a suite of KPIs reflecting

the quality of outputs, including health, safety, environment,

availability, reliability, integrity and maintenance

management, etc.

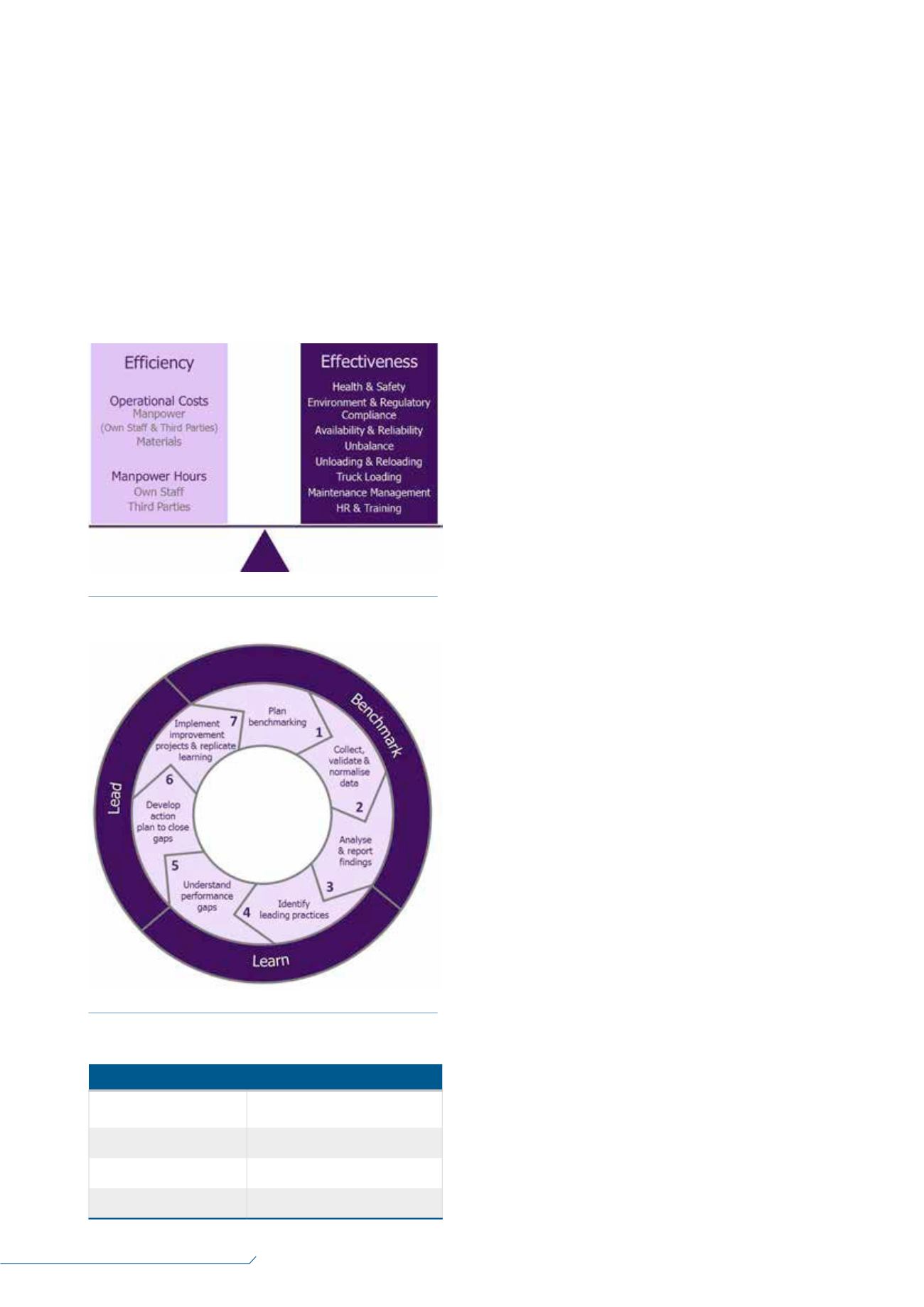

Performance analyses are made between terminals and

performance gaps determined. The process follows the

Juran Benchmarking Cycle

©

(Figure 2), which provides a

robust, systematic approach, commencing with

benchmarking planning, through data collection, validation,

analysis and reporting. The output of this analysis enables

improvement opportunities to be targeted, whilst

formulating appropriate deployment activities in order to

implement change and realise improvements in

performance.

Like-for-like comparison

Central to effective benchmarking is the need to be able to

compare different processes, functions, or, as in this case,

LNG receiving terminals on a like-for-like basis. No two

terminals are the same, so it is essential that an appropriate

methodology is used to account for the differences so that

valid performance comparisons can be made. If this is not

achieved, then any subsequent analysis is of limited value.

To enable this, it is necessary to normalise performance data

in a way that allows like-for-like comparisons.

One approach often seen is to use volumes of send-out

gas or terminal capacity as normalising factors. However,

these are crude approaches and there is no correlation

between them and either expenditure or manpower time.

Therefore, a unique and innovative methodology was

incorporated that enabled like-for-like comparisons of costs

and manpower levels between terminals of differing size

and design – the Juran Complexity Factor

®

, which is based

upon the technical complexity of a terminal and the

corresponding effort required to operate and maintain it. The

methodology has an excellent correlation with both OPEX

and manpower time and, therefore, provides a robust

methodology for enabling direct comparisons of different

terminals.

Operational context

Global changes in the LNG market have resulted in a marked

impact on the operating environment of European LNG

receiving terminals during the four years that the consortium

has been working together. Table 1 illustrates the average

changes in terminal utilisation, send-out volumes and

vessels unloaded between 2012 and 2015, based upon data

obtained from the participating terminals. The reduction

in utilisation has seen natural gas send-out volumes fall to

minimum levels, bringing with it significant challenges both

technically and commercially. All terminals recognised the

need to minimise cost, whilst adjusting to new operational

envelopes with minimum delivery, which became a key

focus for the consortium in the initial years.

Rising to the challenge

The participating terminals have used the benchmarking

to support them as they strive to meet the increasing

challenges of operating during these difficult times. The

comparative measurement of efficiency conducted in the

benchmarking enabled the identification of cost gaps and

savings potential for each participating terminal, should

Figure 1.

The benchmarking scope.

Figure 2.

The Juran Benchmarking Cycle

©

.

Table 1.

Performance averages for the benchmarking group

Peformance area

Change in performance

(2012

–

2015)

Terminal utilisation

38% decrease

Terminal send out

44% decrease

Number of vessels unloaded 25% decrease