The exact amount of heat input and BOG generated

and to be managed depends on a range of parameters.

The following are the most important:

The saturated vapour pressure of the LNG in the

unloading vessel.

The targeted saturated vapour pressure of the LNG

in the reloading vessel, which, in turn, depends on

the voyage the ship has to make, whether the ship

consumes BOG or not, and the maximal saturated

vapour pressure on its unloading point.

The composition of the LNG.

The LNG infrastructure itself, which is determined by

pressure losses during loading and unloading, and

thus heat input from the piping system, as well as the

required pump energy and the associated heat input.

In order to optimise the terminal’s BOG management

system, four additional reciprocating four-stage six-cylinder

compressors from IHI are being added on top of the

compressor capacity that has already been installed. These

compressors can be used either in low pressure mode (from

tank pressure up to 4 barg) or in high pressure mode (from

tank pressure up to 80 barg). When running in high pressure

mode, the gas runs through the four stages of the

compressor. In low pressure mode, the first two stages are

switched to stage one, while the cylinders of stage three

and four run idle.

Pluto LNG, image courtesy of Woodside

Our clients count on us to provide quality end-to-end

LNG services, on time and on budget.

Our 20,000 strong Oil & Gas professionals offer capabilities in:

›

Liquefaction plant build

›

Completions and commissioning

›

Non-process infrastructure

›

Marine infrastructure

›

Operations and maintenance

›

Telecommunications

›

Re-gasification and receiving terminals

›

Off-sites and utilities

›

Gas processing and handling

›

Pipelines and compressor stations

Proven LNG

Capabilities

SNC-Lavalin Kentz Field Operations is world

renowned for providing multi-disciplinary

construction and technical field services.

snclavalin.com

1290_SL16_OG_AD_IndustryLNG_V02_print.pdf 1 9/28/2016 1:53:06 PM

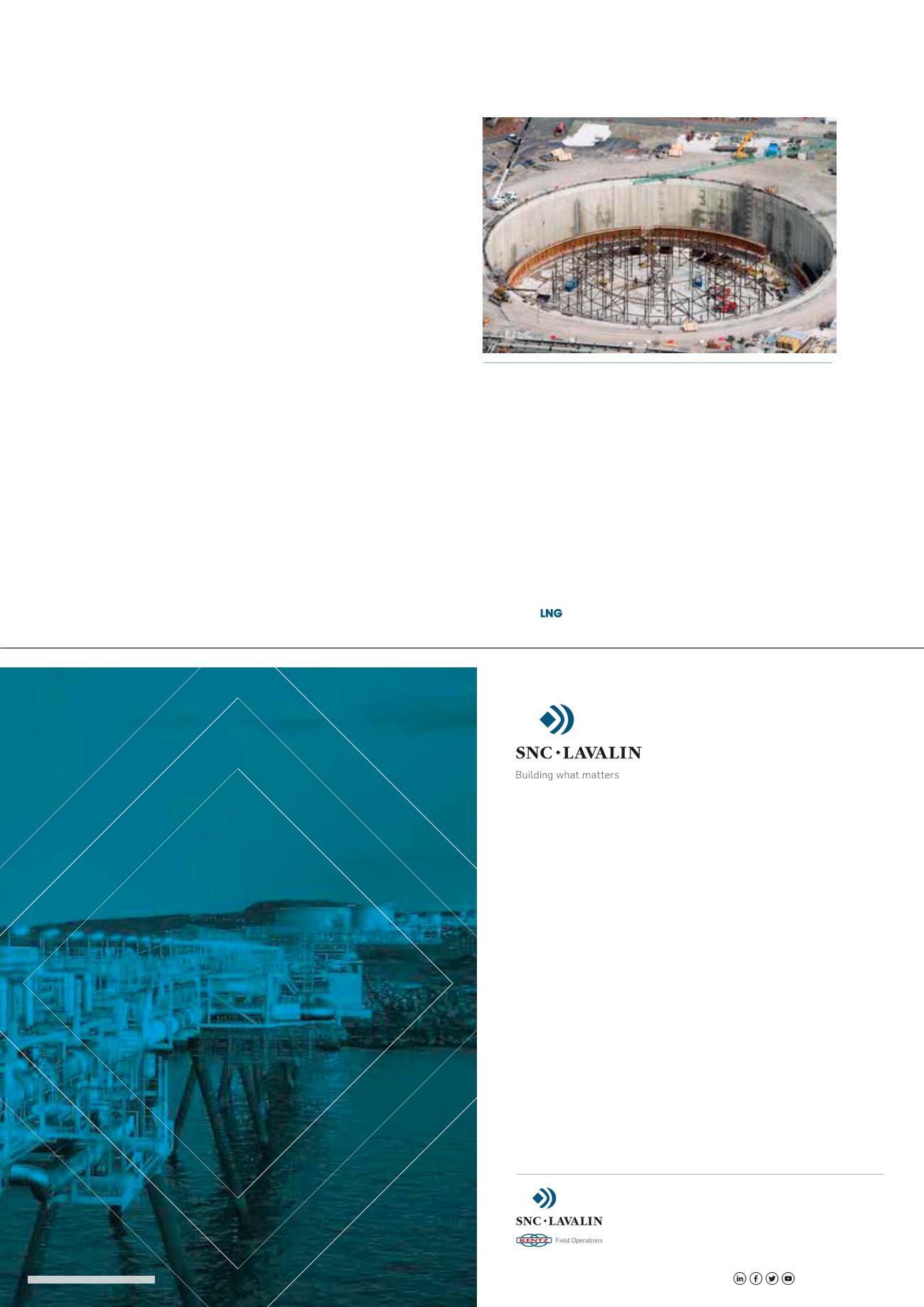

Figure 5.

The fifth tank pit, with construction of the outer tank

wall and metallic roof (Fluxys Belgium – P. Henderyckx).

Conclusion

Today, ship loadings with a loading rate of more than

5000 m³/hr are common business at the Zeebrugge

LNG terminal. With the second jetty coming into

operation in 4Q16, a multitude of services will be

added, including STS transfer. As from 2018/2019,

the LNG terminal will be ready for large scale

transshipments, either STS or ship-to-storage-to-ship,

with loading rates similar to those in an export

terminal.