26

LNG

INDUSTRY

OCTOBER

2016

Felguera-IHI and Balzola. Main subcontracts

have been placed with IHI Corp. (Japan) for the

compressors, Industeel (Belgium) for the 9%

Ni-steel plates, Amec Foster Wheeler (Spain) for

process engineering, Solétanche-Bachy (France –

Belgium) for the diaphragm walls, Esteyco (Spain)

for the civil engineering, and SMM (Portugal) for the

tank mechanical works.

The first activities on site were the construction

of the diaphragm wall and the tank pit. A major

challenge during the construction of the diaphragm

walls was the removal of about 150 rocks that were

approximately 14 m below grade level. These

remnants of the construction of the port in the late

1970s needed to be removed before the wall could

be constructed. Therefore, it was necessary to

execute an extensive detection campaign, a

pre-drilling campaign to drill through the rocks from

grade level in order to weaken them, and a chiselling

(hammering) campaign to break the rocks into

smaller pieces.

The tank’s foundation is now finished, whilst the

outer tank wall and metallic roof are still under

construction (Figure 5). The roof’s airlifting is

scheduled for mid-February 2017, whilst the tank

itself is scheduled to be commissioned by the end of

2018. The compressors are scheduled to arrive from

Japan in early 2017, and to be commissioned in 1H18.

BOG management

Every unloading, loading or direct STS

transshipment operation causes a significant heat

increase to the already-boiling LNG, resulting in

the generation of BOG and leading to an increase

in pressure. The key to an optimal transshipment

process thus lies in the BOG management system.

In a terminal with two jetties, four major customers

and additional berthing rights and reloading services

for both small scale and large scale vessels, a

multitude of operational scenarios exist. Dozens of

scenarios were analysed in order to calculate the

required compressor capacities needed in line with

all contractual requirements.

The traditional way of managing BOG in an

import terminal is to recondense it in the send-out

flow by sending it through a recondensor, which is

operated at a higher pressure than inside of the LNG

storage tanks and the ship, and then sending it

through the high pressure pumps and vaporisers.

This process causes approximately 25% of the ship’s

cargo to be vaporised into the gas pipeline grid as a

combination of liquid flow being vaporised and

recondensed BOG. However, in the case of

Yamal LNG, only ‘pure’ transshipment services are

required, in which the volume to be reloaded needs

to be maximised. Therefore, the aforementioned

method is not the optimal solution and instead, the

generated BOG is directly compressed into the

transport grid by a battery of compressors, limiting

the volume of non-reloaded LNG to the BOG alone.

Safety measures

Several safety measures are implemented in order to

ensure safe operations. A retention wall will be added

on top of the diaphragm wall, making it possible for the

outer layer to accommodate the full volume of the LNG

tank. The area between the outer layer and the storage

tank is also protected by high expansion foam systems,

which can flood the entire impounding area with foam

within a couple of minutes. All storage tanks on the

Zeebrugge LNG terminal are also equipped with deluge

systems protecting them in case a neighbouring tank is

on fire. Furthermore, the LNG pipelines run over concrete

impounding, which is designed to collect all LNG in case

of an LNG leakage.

Figure 4.

Construction of the diaphragm walls – segment

under bentonite.

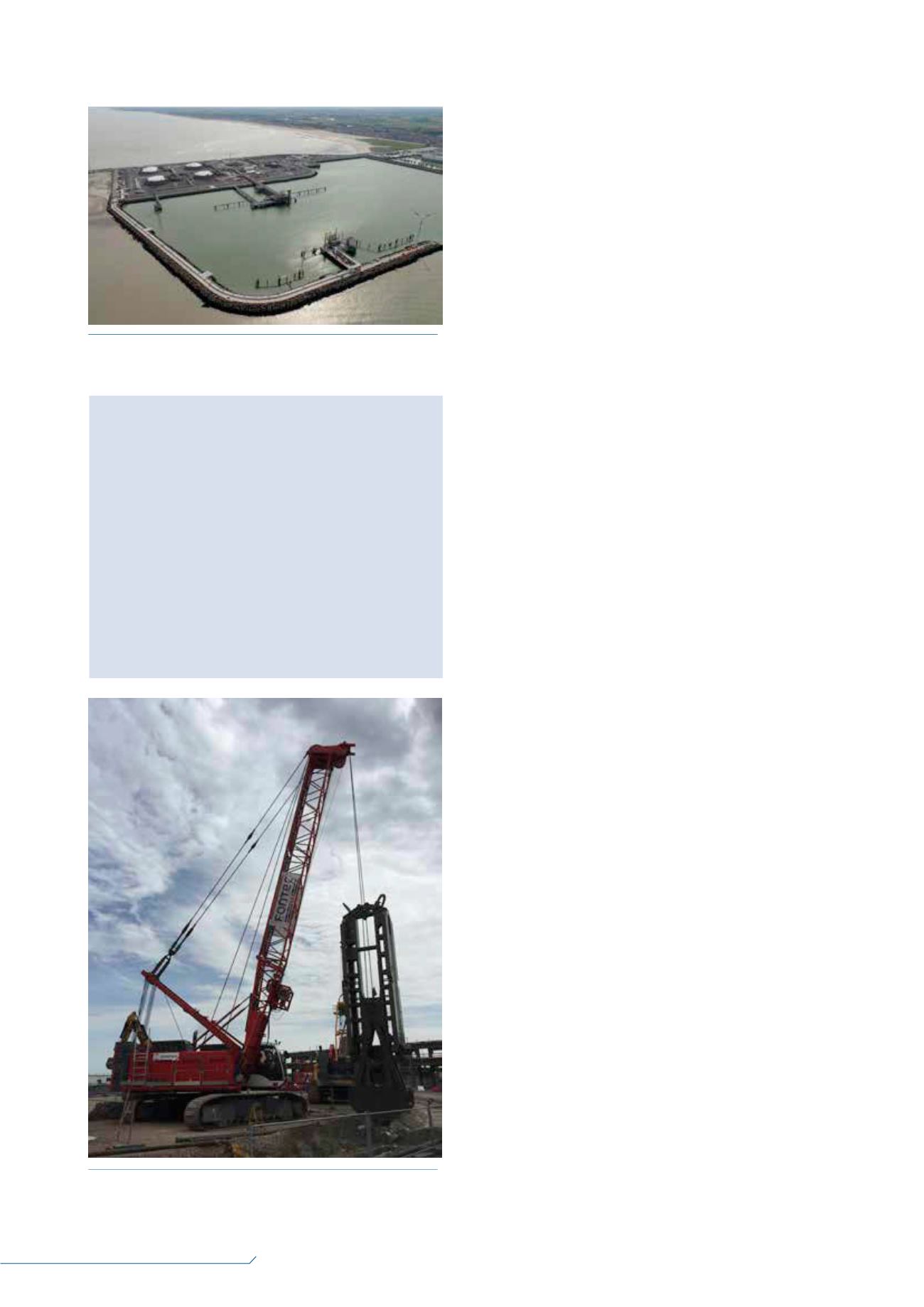

Figure 3.

Overview of the Zeebrugge LNG terminal with two

jetties and fifth tank currently under construction (Fluxys Belgium

– P. Henderyckx).